Axle Lubricants

Check the gear box, tandem box, axle and hydraulic

motor oil levels quarterly, shown in Figures 5-1 and

5-2). Add more gear oil if needed. Change the oil on

these components every year for optimum performance.

NOTE: The manufacturer recommens axle lubricant

that meets API GL-5/MT-1 or SAE J2360

specication.

Use the following procedure to change oil at the various

oil plug points as shown:

1. Park machine on level ground.

2. Remove the oil plug(s) shown in Figures 5-1 and

5-2.

3. Add oil until it starts coming out of the level plug.

4. Replace the level plug.

5. Allow the axle to sit level for at least ve minutes to

allow the oil to ow throughout components.

6. Remove the level plug and check oil level.

7. Add more oil if needed.

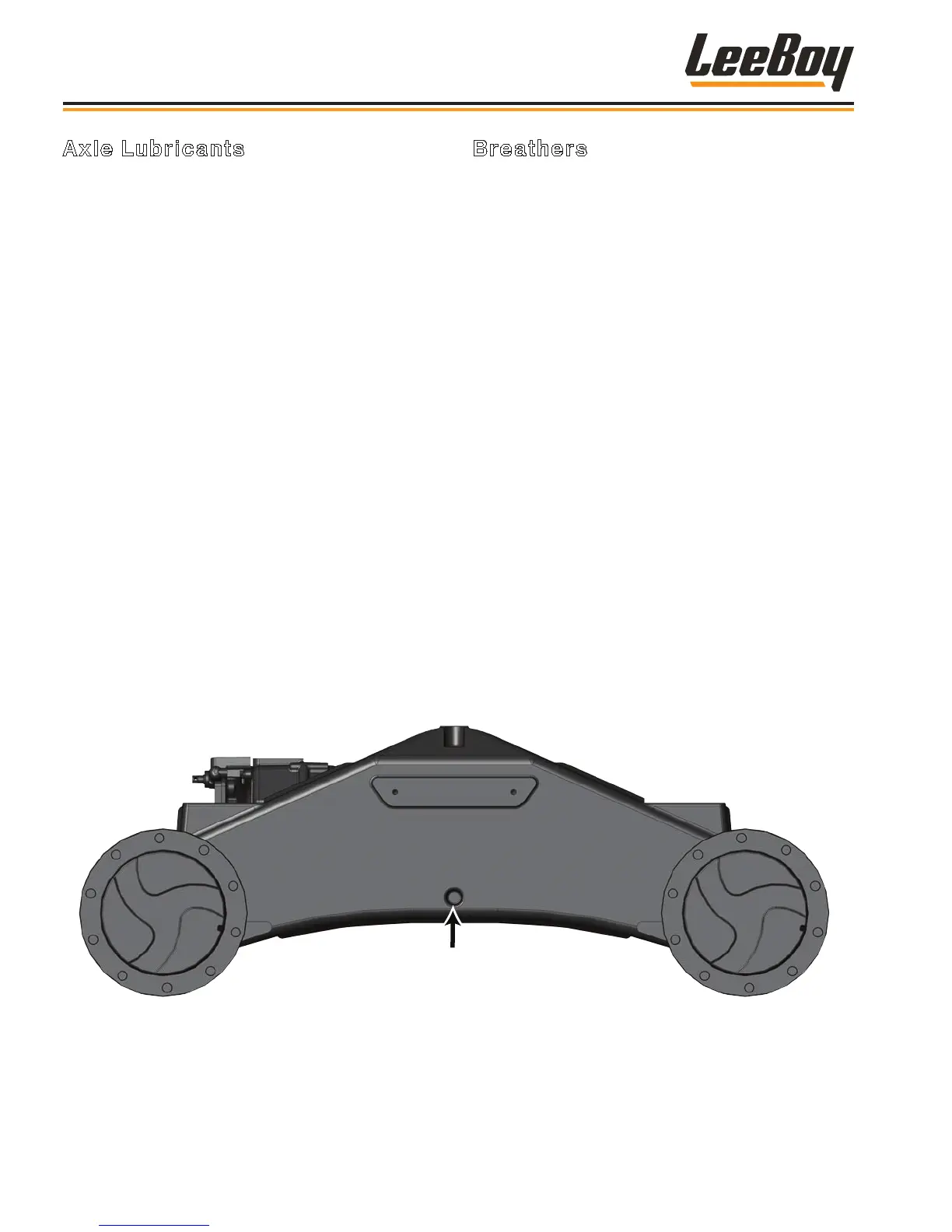

Side View

Tandem Oil

Level Plug

Figure 5-1. Side View of Bogie Axle

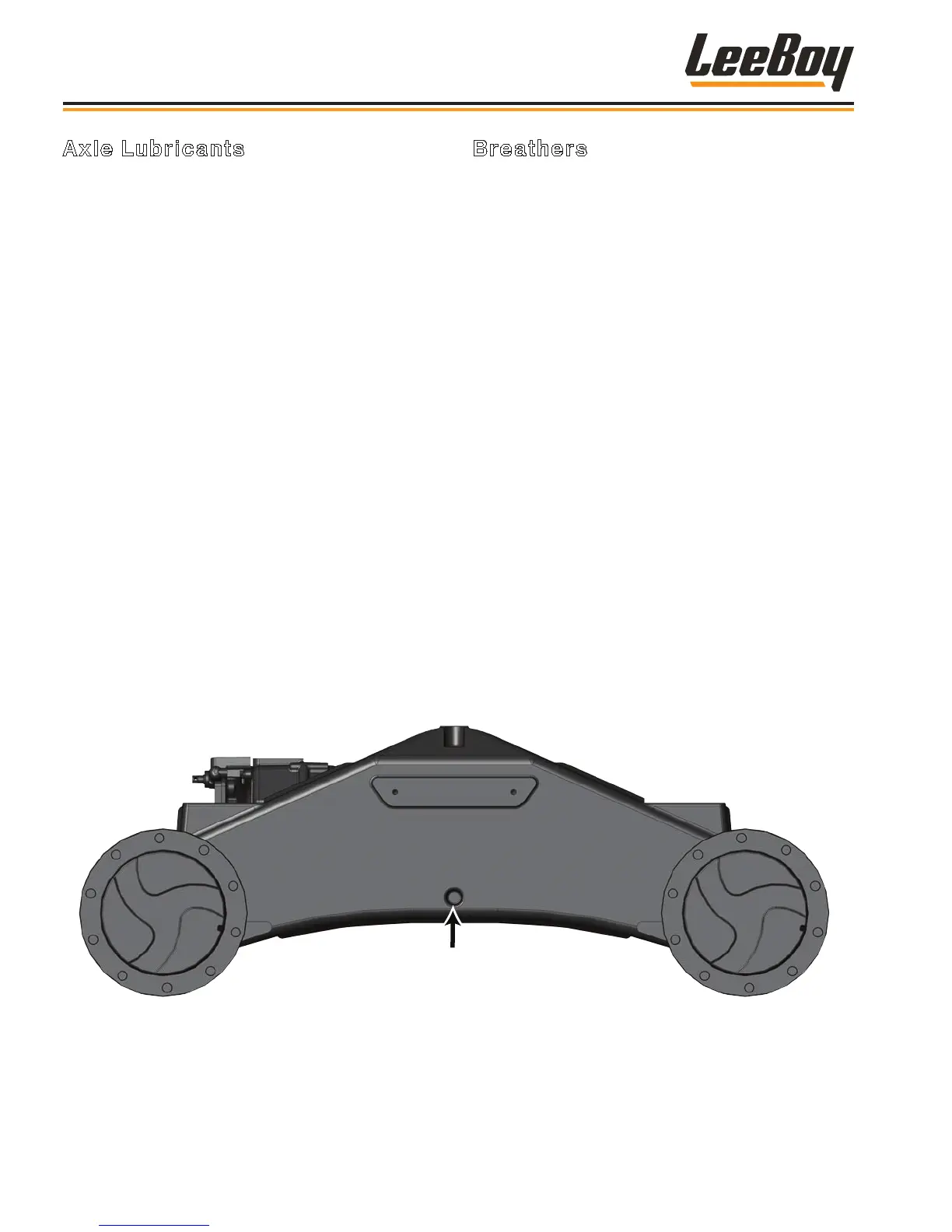

Breathers

Hydraulic gear boxes, axles, pumps and tanks need to

“breathe” as air is drawn in when hydraulic components

activate. Breathers stop water, dirt and debris from

contaminating the oil. If the breathers are clogged, the

resulting heat and pressure increase will force lubricant

to escape through seals and joints in the housing,

leading to bearing or gear failure. To prolong the

operational life of a bogie axle, regular inspections and

maintenance of the breathers is essential. (Figure 5-2)

• Always inspect the breathers when checking oil levels.

Simply dusting and brushing off the gear breathers

regularly will keep out dirt and debris that can clog the

breathers.

• Check for oil leaks. Leaks indicate that seals

have failed, thus allowing dust, debris and water to

contaminate the oil.

• If the breathers and/or seals are damaged, they

should be replaced without delay to prevent internal

contamination and inadequate lubrication.

• To replace, simply unscrew the breather and discard,

then reinstall the new breather.

Maintenance

LeeBoy 685D Motor Grader5-8

Loading...

Loading...