Moldboard Lift Cylinders

1. Park the grader on a level surface in a designated

area where oil does not touch or run off onto the

ground.

2. Lower the moldboard to the ground.

3. Engage the park brake, shut down the engine and

place wheel chocks on wheels for safety.

4. Use a sling or other means of supporting the

moldboard lift cylinders.

5. Disconnect, plug and tag the hydraulic hoses

connected to bottom of one cylinder, being very

careful to prevent any contamination when plugging

the hydraulic hose ttings.

NOTE: Inspect the hydraulic ttings. Replace any

damaged or worn ttings.

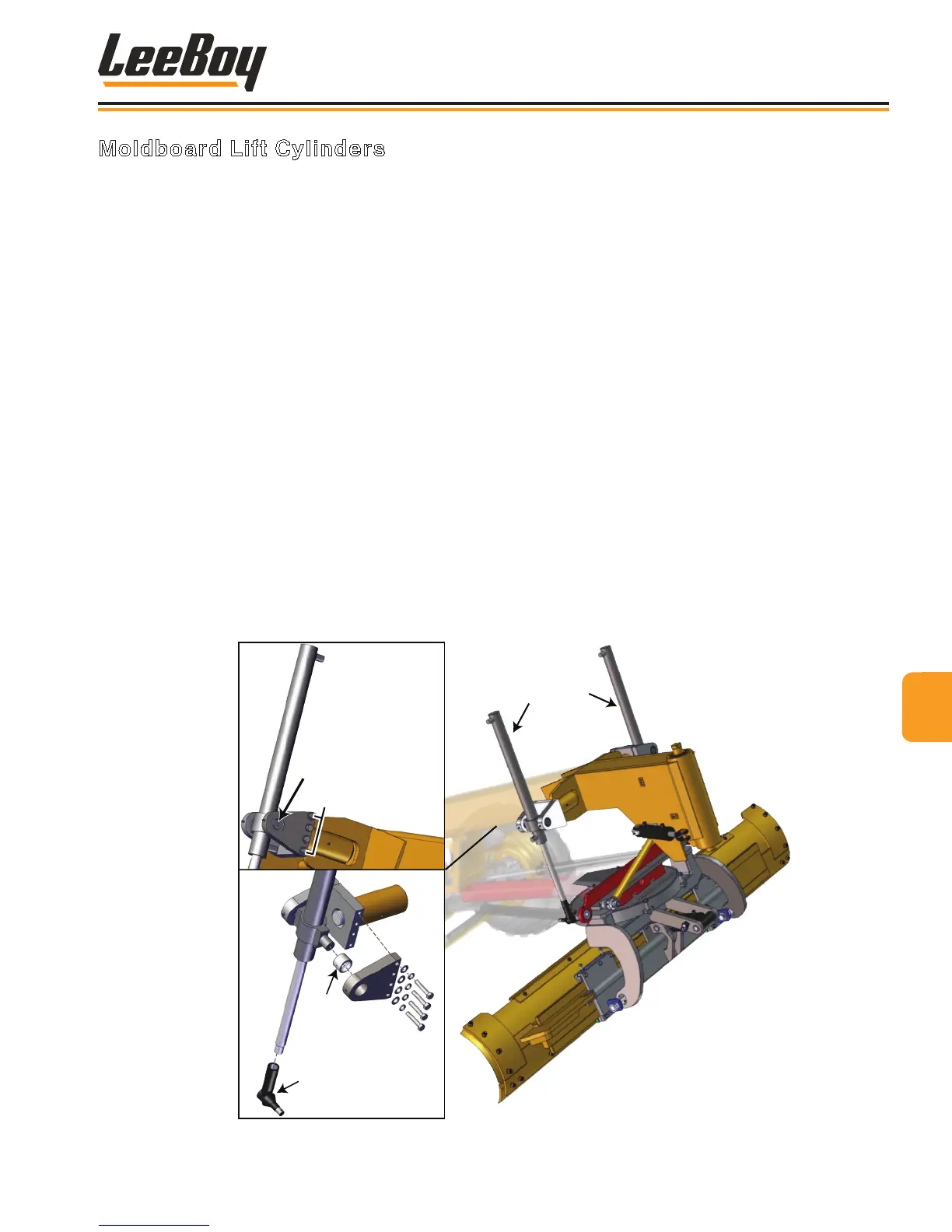

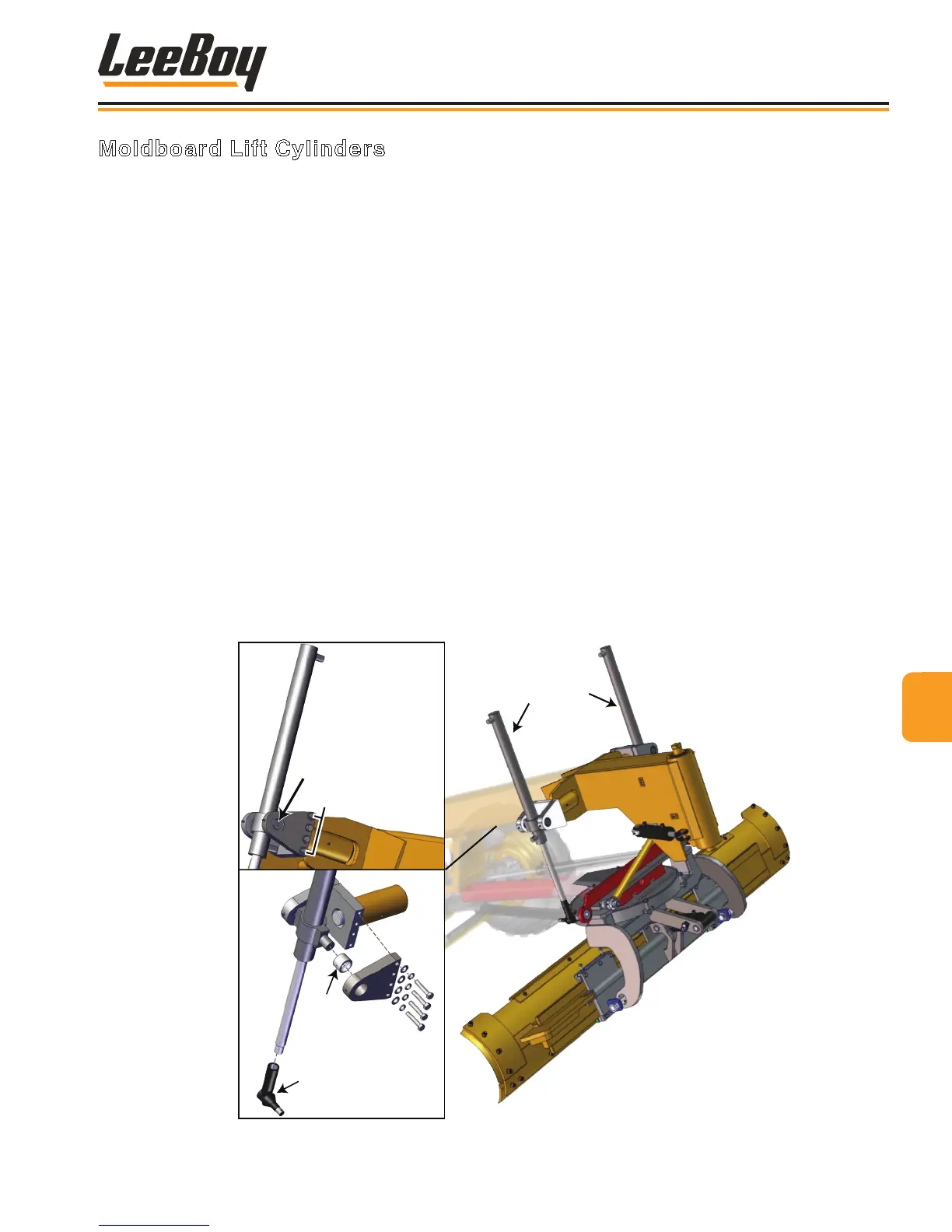

6. Use ats on cylinder rod to unthread cylinder rod

from ball joint. If the ball joint needs to be replaced,

separate tapered ball joint stud from turntable and

remove. (Figure 5-41)

7. Remove the four (4) bolts and washers on the front

side of the lift cylinder, then the lift cylinder mount

slide plate as shown in Figure 5-41.

8. Remove the bushing inside from the cylinder pin.

9. Remove the bushing inside from the cylinder pin.

Carefully remove the lift cylinder from the frame

to remove it. Clean the area thoroughly before

installing new cylinder.

10. Position the new moldboard lift cylinder into place.

11. Insert bushing (ensuring the grease tting is in

place), then position the side plate and secure with

washers and bolts. Torque bolts. (See Torque

Tables, Section 2)

12. Repeat Steps 4 - 11 on the other lift cylinder if

needed.

13. Reconnect the hydraulic hoses according to the

tags for correct reconnection.

14. Using a grease gun, lubricate the rods on each

cylinder.

15. Start the engine and idle for a few minutes to ensure

the hydraulic oil has warmed in the system.

16. Raise and lower the moldboard several times to

ensure proper operation and check for leaks.

Lift

Cylinders

Bolts

Cylinder Pin

(Front Side

of Cylinders)

Bushing

Ball Joint

Figure 5-41. Moldboard Lift Cylinders

5

Maintenance

LeeBoy 685D Motor Grader 5-35

Loading...

Loading...