HYDRAULIC SYSTEM

The hydraulic system is composed of two major

component groups--the hydrostatic drive and the

auxiliary hydraulic group. The hydraulic motors and

cylinders use the same hydraulic oil reservoir and

hydraulic oil supply. Solenoid valves, ow-control valves,

dividers and other components allow simultaneous

function and control of all hydraulic systems. A

30-gallon hydraulic tank with suction strainers, charge

pressure and return lters stores and cleans the

hydraulic uid. An oil cooler is mounted with the engine

radiator to complete the hydraulic system.

The hydrostatic drive group consists of an axial piston

hydrostatic pump coupled to the rear of the diesel

engine. A hydraulic motor drives the rear axle. The

auxiliary hydraulic group consists of a two-section

gear pump mounted on the rear of the drive pump. If

equipped with the AWD option, a second axial piston

drive pump is installed and connected to the front wheel

drive motors.

ALWAYS use an equivalent grade of

hydraulic uid. Using hydraulic uids that do not

have equal characteristics can result in substandard

performance or possible failure of the hydrostatic

system. Contact your authorized LeeBoy dealer if

you need assistance.

Always wear eye protection when

inspecting for leaks in the hydraulic system. Never

use your hands to locate leaks as hydraulic uid

under pressure can pierce the skin and cause

serious injury and toxic reaction.

Never attempt makeshift repairs using

tape, clamps or cements in the hydraulic system.

The system operates under extremely high pressure

and such repairs could fail, causing serious injury.

Inspect the motor grader for hydraulic leaks daily.

Check that all ttings are secure and tight weekly. If

leaking uid is found, it is probably on the pressure

side of the hydraulic system. DO NOT OPERATE the

machine until the hydraulic leak is repaired.

Leaks on the suction side of the hydraulic system are

more difcult to nd and more serious since air or dirt

introduced into the system causes rapid component

wear and eventual failure. Some symptoms of suction

leakage are:

• Hydraulic uid “foaming.”

• Sluggish system operation.

• Unusual noises in the hydraulic pumps or motors.

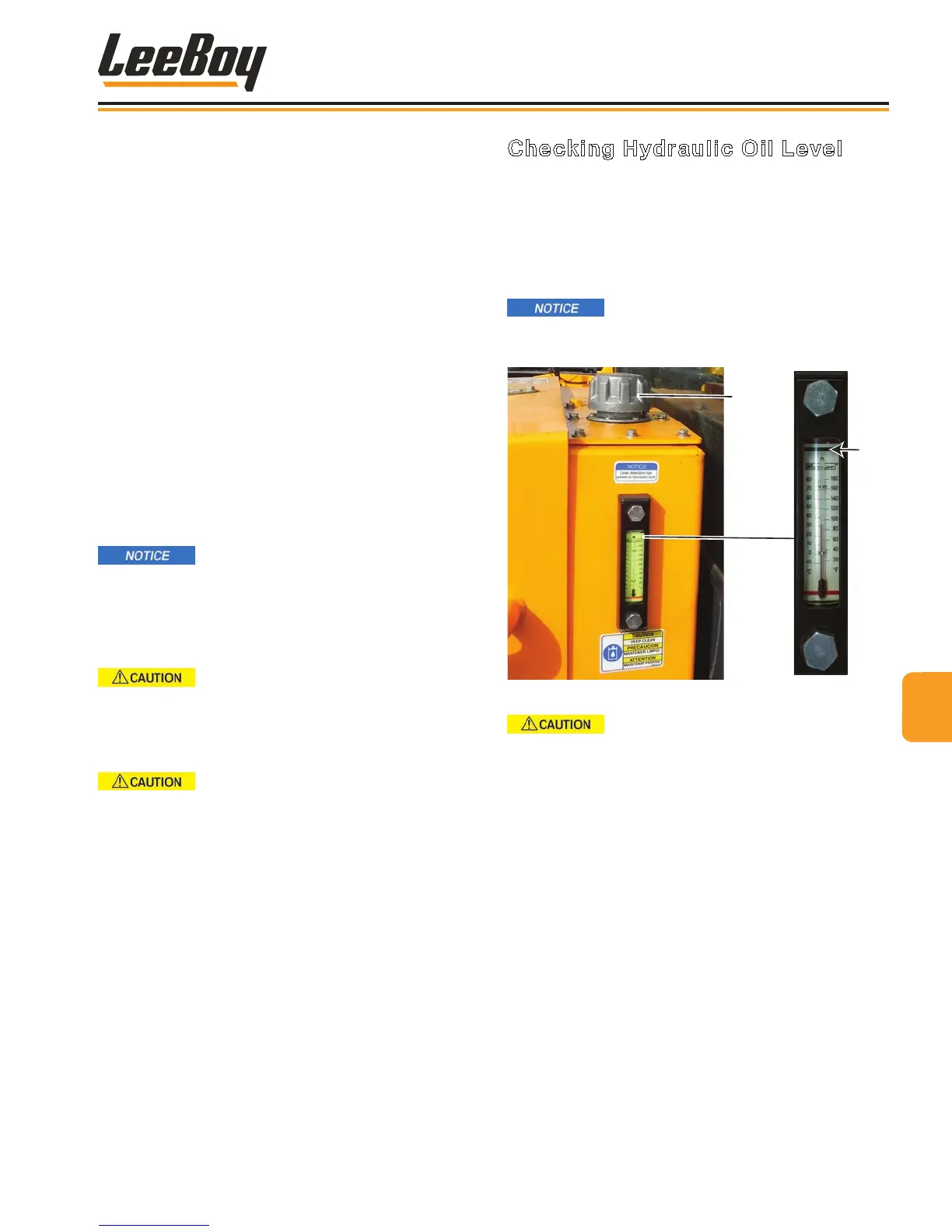

Checking Hydraulic Oil Level

The hydraulic oil tank and sight gauge is located on the

right side of the machine. The hydraulic oil ll cap is

accessed on the right side of the grader just behind the

operator platform. (Figure 5-28)

NOTE: Wait 10 minutes after engine has been shut

down before checking hydraulic oil.

Oil level is determined by sight gauge.

Hydraulic oil should be added if the oil level falls

below the ll line. Never ll above the black ll line.

Hydraulic

Oil Cap

Sight

Gauge

Fill

Line

Figure 5-28. Hydraulic Sight Gauge and Filler Cap

Use extreme caution when removing

the ller cap to prevent foreign matter from entering

the hydraulic tank.

If hydraulic level is low:

1. Clean around the hydraulic oil ller cap before

removing to add hydraulic oil to the tank.

2. Fill tank to the black ll line on sight gauge.

3. Screw the hydraulic oil ller cap back onto the

hydraulic tank.

5

Maintenance

LeeBoy 685D Motor Grader 5-25

Loading...

Loading...