COMPONENTS OVERVIEW

The LeeBoy 685D Motor Grader is a compact motor

grader with the functionality of a large motor grader.

It’s versatility and specialized applications include

spreading base materials, ditch and shoulder projects,

ne grading, medium cutting and even snow removal.

Graders can also be used for bank sloping, leveling,

crowning, and road/runway maintenance. This self-

propelled, wheeled grader has an adjustable, 11-foot

(3.35 meter) moldboard blade positioned between the

front and rear wheels. An optional 12-foot (3.65 meter)

moldboard is also available. Optional attachments

include an 8-foot (2.4 meter) front blade, front or rear

scariers or a blade-mounted, ip-down scarier. Be

familiar with all the grader’s components and optional

attachments purchased before operating this machine.

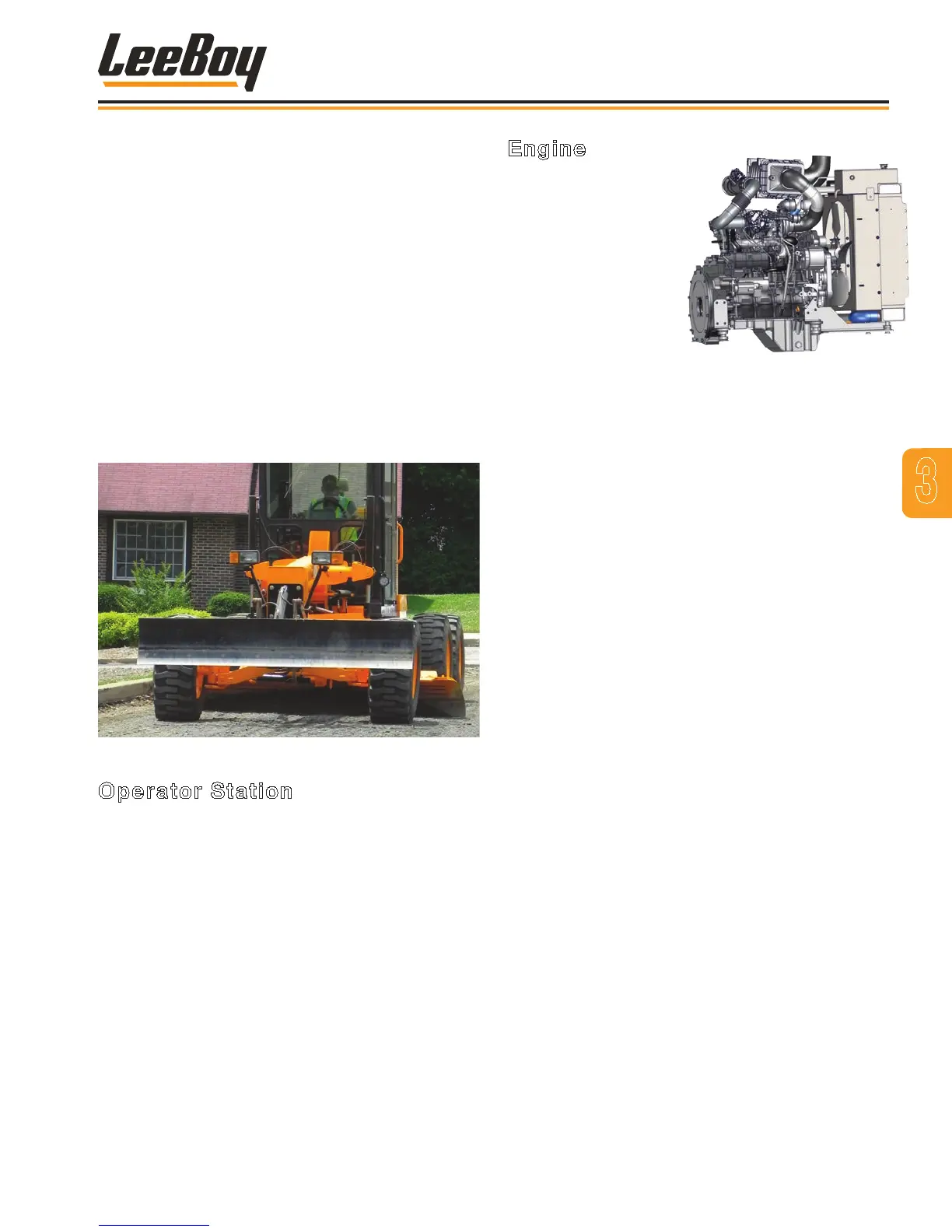

Operator Station

The 685D Motor Grader is equipped with a canopy, but

an optional fully-enclosed cab version offers additional

operator comfort on the job site. Air conditioning,

heating, and other options are also available for a cab

model.

Levers, control switches and joystick controls are within

easy reach for operator comfort. The PV485 digital

controller unit on the steering control panel includes

throttle control, tachometer, fuel gauge, oil pressure

gauge, coolant temperature, voltmeter and hour meter

along with gauges and warning alerts. The steering

column can be tilted for comfort. Complete control

panel information is described in the following pages.

Engine

The 685D Motor Grader

is equipped with a

Cummins QSF3.8 Tier

4F diesel engine. This

Tier 4 Final fuel-efcient

engine offers the latest

in innovative emission

solutions to reduce diesel

particulate matter (DPM)

and other toxins released

into the air.

Advanced emission-control devices and low-sulfur fuel

requirements--only Ultra-Low Sulfur Diesel (ULSD)

can be used in this engine--combine with new after-

treatment methods. The SCR system is an efcient,

effective means of ltering dirt and other contaminates

for optimum engine performance and reducing air

pollution from exhaust emissions. The Selective

Catalytic Reduction (SCR) system precisely injects

Diesel Exhaust Fluid (DEF) into the engine’s exhaust

system to transform those toxic exhaust gases into

harmless water vapor and nitrogen. SCR technology is

also cost-effective and fuel-efcient.

The High-Pressure Common Rail (HPCR) fuel system

offers a new level of cleanliness, performance and

fuel economy. The fuel lter removes contaminants

from diesel fuel before it ows into the injection pump,

providing better protection against harmful particles.

The Direct Flow™ air ltration system holds 30 percent

more dust particles than conventional lters, enabling

longer service intervals and reducing maintenance

costs. The radiator cools the engine. A mechanically-

driven fan removes heat, saves horsepower and

reduces noise.

Lockable engine access doors on both sides of the

grader allow convenient access to components with

vandalism protection.

Refer to the Engine Owner’s Manual accompanying your

machine for additional engine information.

3

Components

3-3LeeBoy 685D Motor Grader

Loading...

Loading...