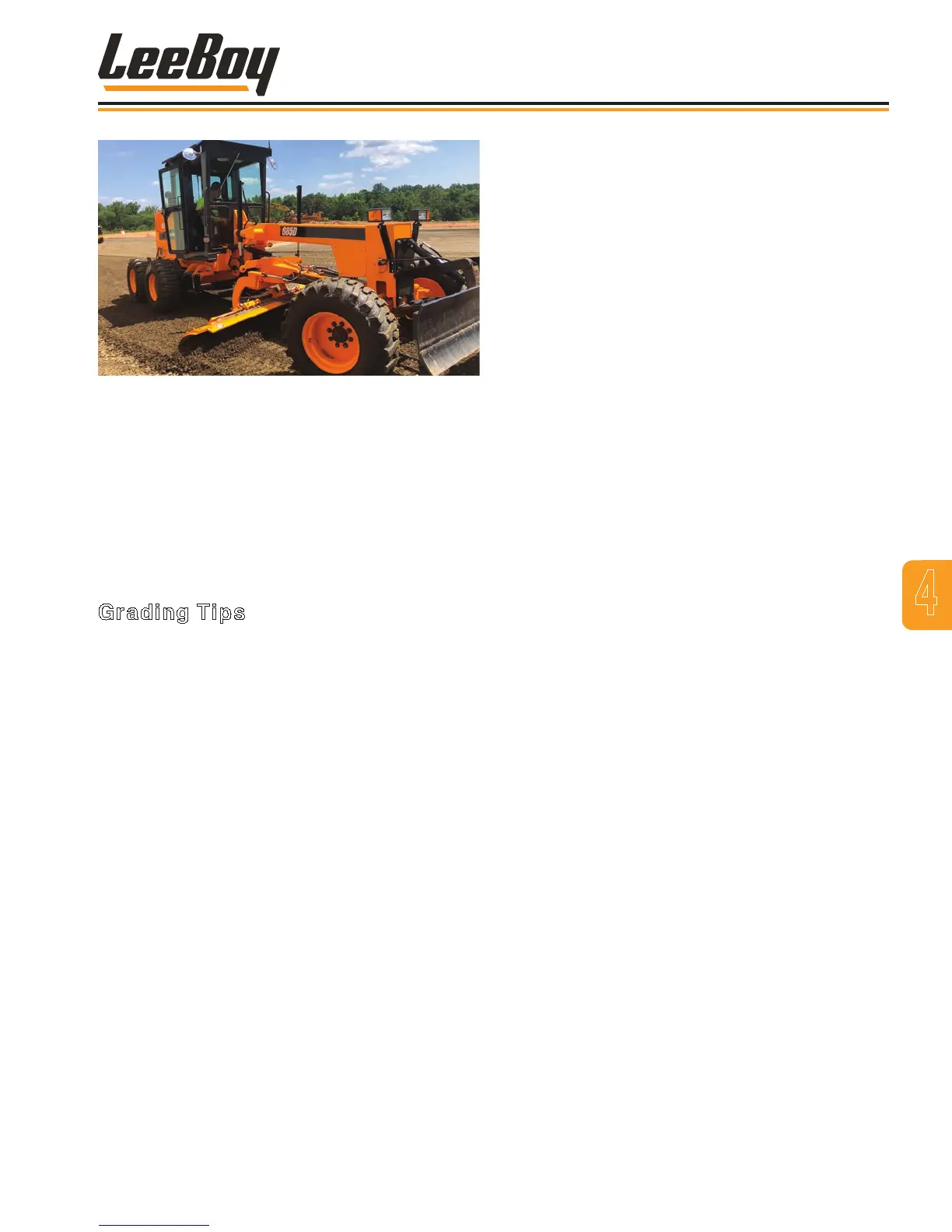

Figure 4-48. Operating the 685D Motor Grader

OPERATING TECHNIQUES

The information provided on the following pages are

basic grading techniques. Every road construction

project is different with a unique set of variables

operators must take into account, such as terrain and

weather conditions, that affect operation. Mastering

such versatile grading skills requires experience.

Grading Tips

The following are general tips for project success when

operating your motor grader:

• Keep your grader and its attachments in good

mechanical condition. Pay extra attention in checking

for wear on the moldboard blade edge often. If

the blade edge is worn or damaged, contact your

authorized dealer for replacement.

• Be very familiar with the controls, attachments and

component functions. Be especially familiar with

blade movement that are made possible by the

hydraulic controls for different tasks. Know the

settings needed, angle, height, and what you want the

blade to do before you lower it to the ground.

• Every job requires a specic blade setting with the

right speed for optimum production. Be familiar with

the moldboard blade movements. Know what you

want to do before lowering the moldboard.

• Moldboard angles of 10 - 30 degrees can be used for

light, free-owing material. Higher angles of 30 - 50

degrees is required when processing wet or sticky

material, mixing large windrows, and ditch work.

• Remember that pitching, or tilting the top of the

moldboard tip forward or backward, changes the

depth of the cut across the entire moldboard.

• If material starts to ow around the leading end of the

moldboard or the rolling action stops, increase the

blade angle.

• Apply only enough downward pressure with the

moldboard to accomplish the task. Excessive

pressure, especially on hard, dry surfaces, causes

rapid cutting edge wear, requires more horsepower

and fuel, and reduces productivity.

• Choosing the right speed for a task is just as important

as the moldboard angle. Drive slowly for delicate

work, but faster if removing rocks from a road surface.

• Avoid moving material more often than needed.

• Trimming is much easier with good compaction.

• If dressing a road, the surface should be moist

whether from rain or hosed from a water truck. Ensure

there is good drainage by grading with appropriate

crown.

• Articulating the rear frame toward the toe of the

moldboard by 2 - 5 degrees helps reduce the

machine’s tendency to bounce. This is extremely

effective when cutting “washboards.”

• Wheel leans can help an operator make steering

adjustments without taking hands off the controls.

Wheel lean is also useful for moving heavy windrows.

• Graders remove snow the same as snow plows. Be

sure to raise the moldboard 1/2 to 1 inch (1.3 - 2.5 cm)

if removing snow from uneven pavement or other

surfaces to prevent damage to the blade.

4

Operation

LeeBoy 685D Motor Grader 4-29

Loading...

Loading...