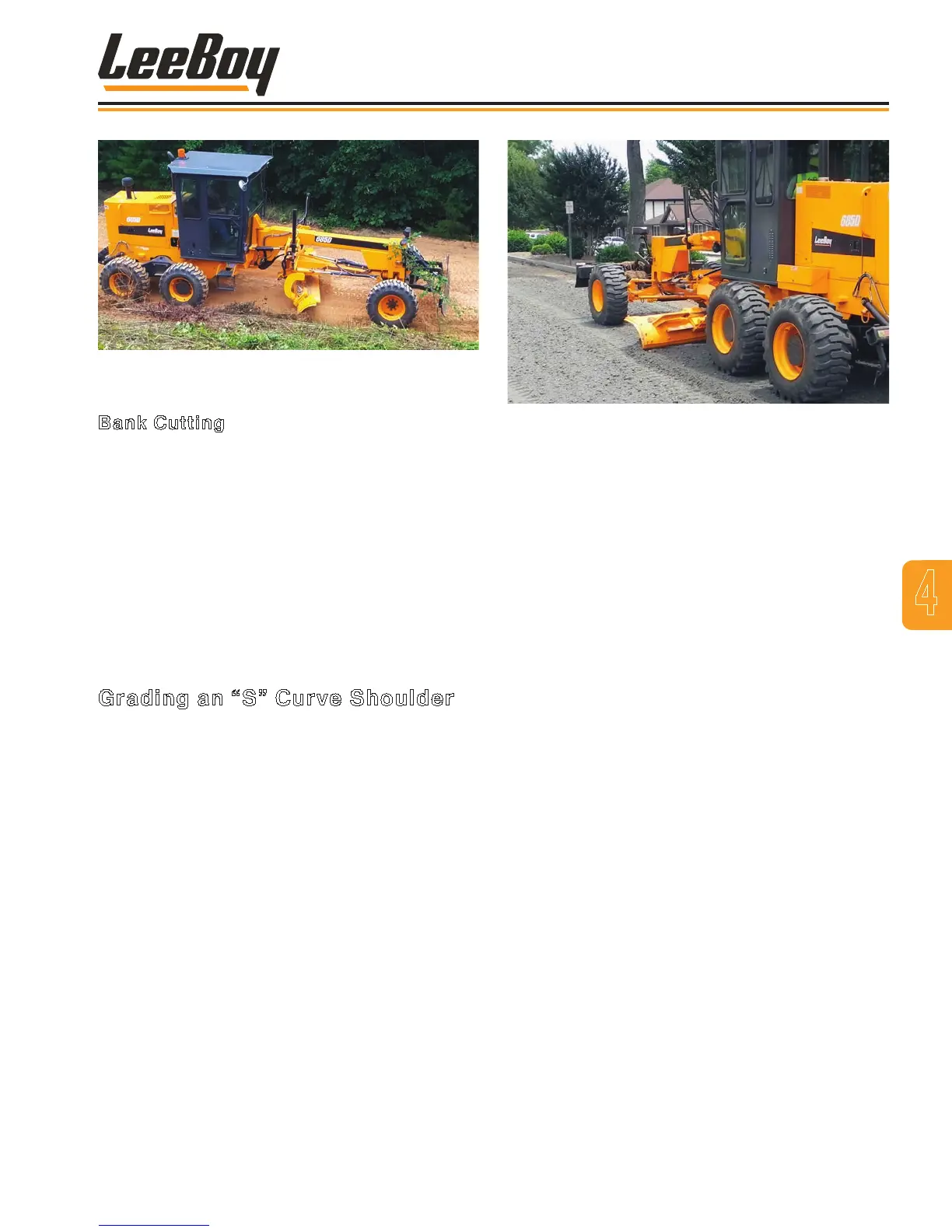

Figure 4-54. Bank Cutting

Bank Cutting

1. Make a rst pass at base of bank to level and

smooth a platform for the machine.

2. Tilt the moldboard slightly forward and sharply

angle the moldboard so the heel is in the opposite

direction of the bank you’re cutting. (You can

articulate slightly if more reach is needed.)

3. After making the bank cut, make a second pass with

the moldboard less angled but tilted more forward

to clean any loose material from the bottom of the

bank.

Grading an “S” Curve Shoulder

1. Slowly approach the rst curve.

2. Lean the front wheels slightly toward the opposite

direction of the curve to counteract side thrust.

• Push the lever forward to lean the wheels left.

• Pull the lever back to lean the wheels right.

3. Position the toe of the moldboard behind and

outside the front wheel closest to the edge of the

shoulder (in the opposite direction of the wheel

lean).

4. As you straighten the grader when nishing the

curve, return wheels to their normal position.

5. Slowly approach the second curve and repeat

Steps 2 - 4.

NOTE: If a windrow has been created while grading,

make a “clean-up” pass and reshape the

shoulder if necessary.

Figure 4-55. Road Maintenance

ROAD MAINTENANCE

Much of a grader’s road maintenance work involves

smoothing, shaping the travel surface and providing

drainage to prevent road deterioration.

Begin road maintenance work by tipping the top of

the moldboard approximately two inches ahead of the

cutting edge, then adjust to the material conditions.

Maintaining the material rolling action across the

moldboard blade reduces the horsepower required and

provides maximum productivity.

• The most important factor in road maintenance

grading is providing and maintaining a good drainage

system. Drainage of water from the road surface to a

ditch, even a minimal ditch, helps maintain good road

conditions longer.

• Remember that tipping the moldboard forwards or

backwards changes the depth of cut across the entire

moldboard. The best time to reshape earth and gravel

roads is after it’s rained. Dry roads should be sprayed

with water before grading for easy compaction and to

minimize dust while working.

• Articulating the rear frame toward the tow of the

moldboard 2 - 5 degrees helps reduce the motor

grader’s tendency to bounce.

• Keep the turntable circle clean. Material buildup may

increase wear and prevent smooth material rolling

action, reducing productivity.

4

Operation

LeeBoy 685D Motor Grader 4-33

Loading...

Loading...