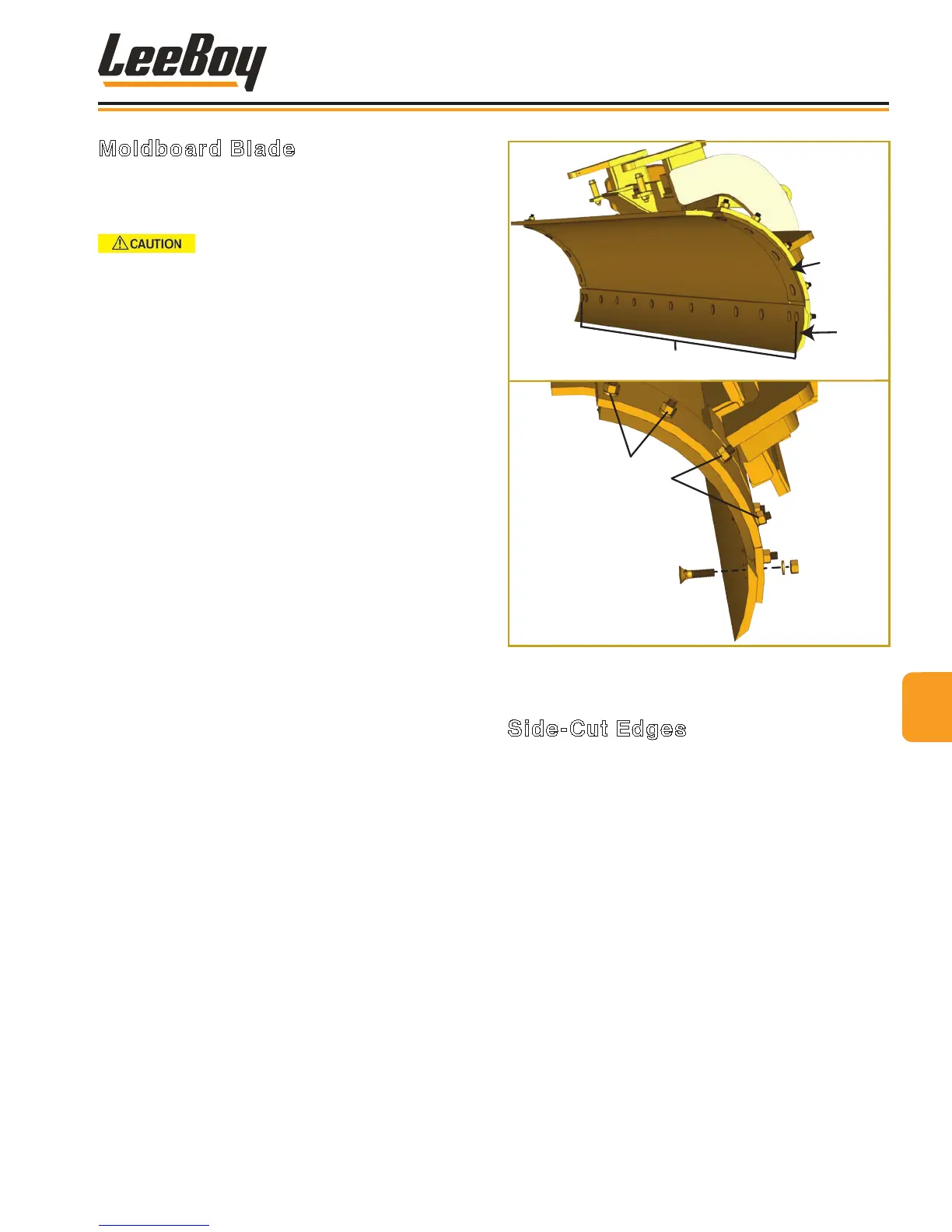

Moldboard Blade

The frequency for replacing the moldboard blade

depends upon the material you’re working with and

operator’s skill in maneuvering the blade.

For safety, wear a hard hat, gloves and

safety glasses when replacing grader attachments.

To replace or change the blade:

1. Block the front and rear wheels to prevent

movement of the machine.

2. Start the grader with the park brake engaged, then

lower the moldboard so it just touches the ground

without any down pressure.

3. Turn off the ignition, ensuring the park brake is still

engaged, and dismount the grader.

4. Working on one section at a time, stand so the blade

is turned away from you, and begin with a bolt on

either end of the blade.

5. Remove the nut and washer, then the bolt. (Figure

5-39)

6. Work from one end to the other until all have been

removed to CAREFULLY dislodge the blade from

the moldboard.

7. Move used blade safely out of the way and align new

blade.

8. Working from one end to the other, install bolts,

washers and nuts, then torque. (See Torque

Tables, Section 2)

9. Discard any worn bolts and replace with the same

size. (See Section 7, Illustrated Parts List)

Blade

Bolts

Remove

nut and

washer

rst.

Side-Cut

Edge

Side-Cut

Edge Bolts

Figure 5-39. Replacing Moldboard Blade

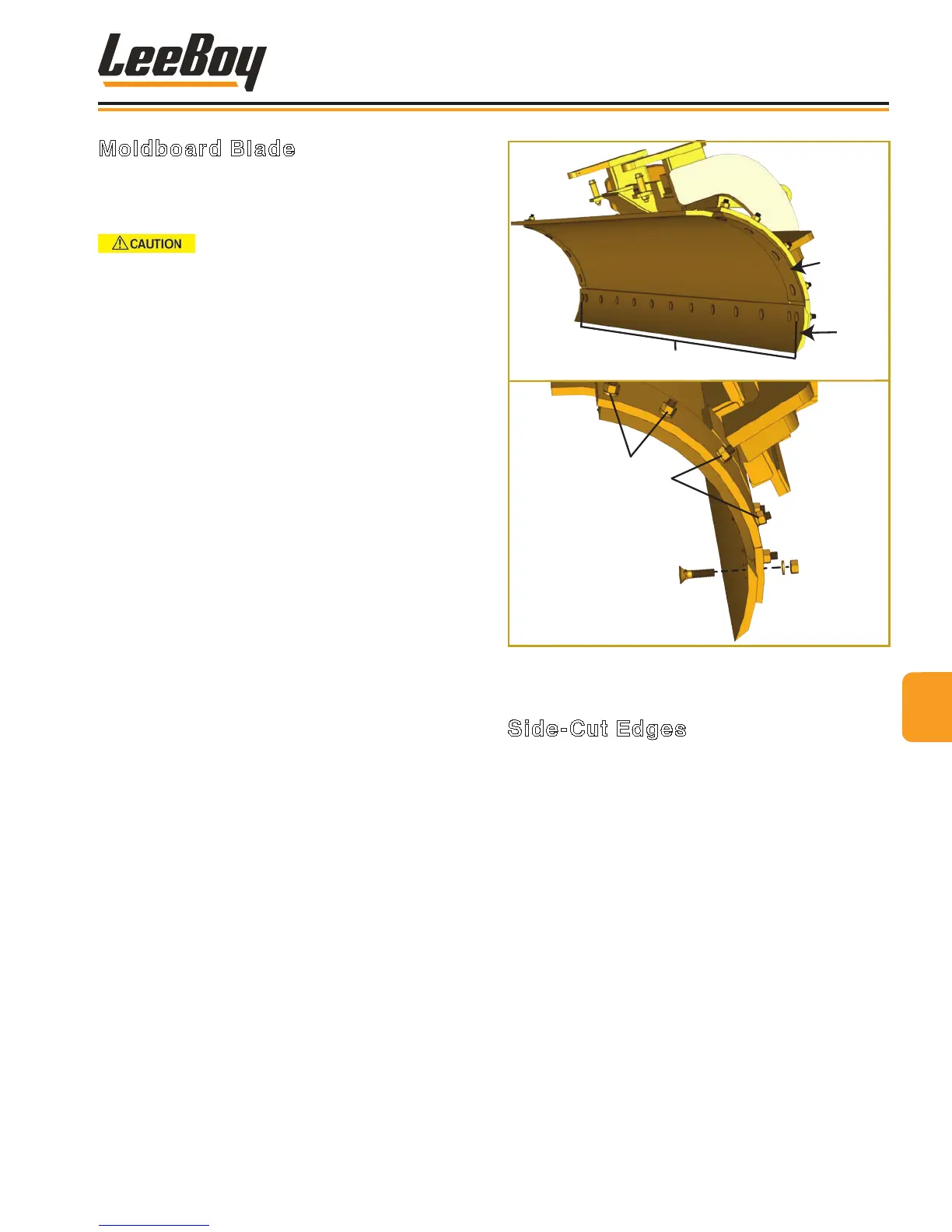

Side-Cut Edges

The moldboard side-cut edges can become damaged

or worn over time, requiring replacement.

Follow the same procedure previously outlined for

removing the bolts to replace the side-cut edges.

(Figure 5-39) There are four bolts on each side-cut

edge.

5

Maintenance

LeeBoy 685D Motor Grader 5-33

Loading...

Loading...