Figure 4-35. Grading with the Moldboard

MOLDBOARD

Grading is most efcient when material is consistently

rolling across the moldboard blade toe to heel. This is

achieved by proper moldboard angle while grading. The

operation of the entire motor grader machine rotates

around the moldboard blade and its precise movement

from the turntable and frame to the hydraulic cylinders

and gears. Levers on the steering column control

moldboard movement.

DO NOT allow others near the grader

while working, especially near the moldboard area.

Serious injury or even death can occur if a bystander

is struck by a moving moldboard.

Moldboard angle is one of the most important elements

of grading since the angle is what allows material to roll

along the moldboard. Improper blade angle and pitch

will overwork the grader and burn more fuel. It can also

cause unnecessary wear on the machine, moldboard

and attachments.

NOTE: When the blade is angled straight across

(perpendicular to the direction of

movement, it is at 0 degrees.

• Most grader work is done at moldboard angles of

10 to 45 degrees.

• Lower moldboard angles (10 - 30 degrees) are

normally used for light, free-owing material.

• Higher moldboard angles (30 - 50 degrees)

are required when processing wet and sticky

material, mixing large windrows, and ditching,

among others. The greater the moldboard angle,

the more material is carried across, allowing for

deeper cuts and heavier grading.

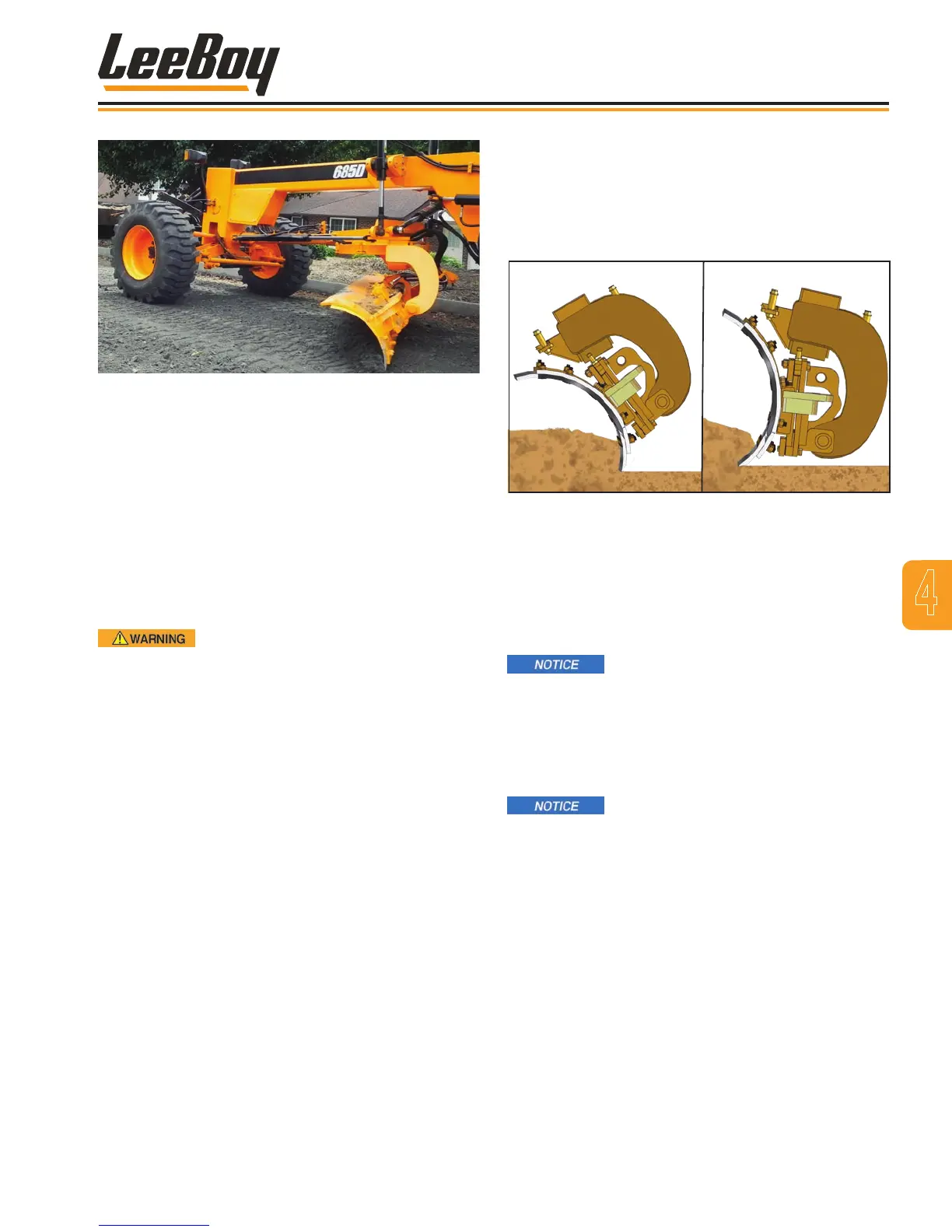

Pitching the moldboard forward or backward changes

the depth of cut across the entire moldboard. (Figure

4-36) Most grading passes start with the top of the

moldboard tilted about two inches (5 cm) ahead of the

bottom. For better penetration, tilt the moldboard more

rearward.

Forward Pitch (Tilt)

Rearward Pitch (Tilt)

Figure 4-36. Moldboard Pitch (Tilt)

• For normal cutting action, the moldboard blade is

used in the upright position only slightly tilted forward.

• Tilting the moldboard forward allows material to roll

for spreading or compacting. Use a forward pitch to

make light cuts, spread material, smoothing material

and typical road maintenance projects.

There are high levels of wear and tear

on the moldboard blade, therefore, inspect the blade

daily. Replace the blade if worn or damaged. (See

Section 5) For maximum cutting edge life in road

maintenance work, maintain consistent moldboard

pitch as frequent position changes can result in

accelerated blade edge wear.

Counteract the resulting side thrust

(inertia) from blade angle and pitch by leaning the

wheels toward the moldboard heel. You may also

need to articulate slightly toward the blade toe for

additional side thrust control.

4

Operation

LeeBoy 685D Motor Grader 4-23

Loading...

Loading...