DEF Dosing Unit Filter

The DEF dosing unit lter prevents foreign objects that

may be suspended in the DEF from entering the dosing

system, which draws DEF from the tank, pressurizes

it, and delivers the DEF through a dosing valve. Any

unused DEF is then routed back to the tank. The DEF

dosing unit lter should be replaced every 4500 hours

or three years, whichever comes rst. It is located on

the left inside the rear access panel on the driver’s side.

Follow these procedures to replace the dosing unit lter:

1. Follow Steps 1 - 4 on Page 5-18 to prepare machine

for DEF system maintenance.

2. Place a container under the DEF dosing unit as a

small amount of DEF may drain from the lines when

disconnected. (Dispose of the uid in accordance

with environmental regulations.)

3. Use a clean, damp cloth to wipe the unit to reduce

the risk of contamination entering the DEF system.

Debris can cause permanent damage and

premature failure in the DEF dosing unit.

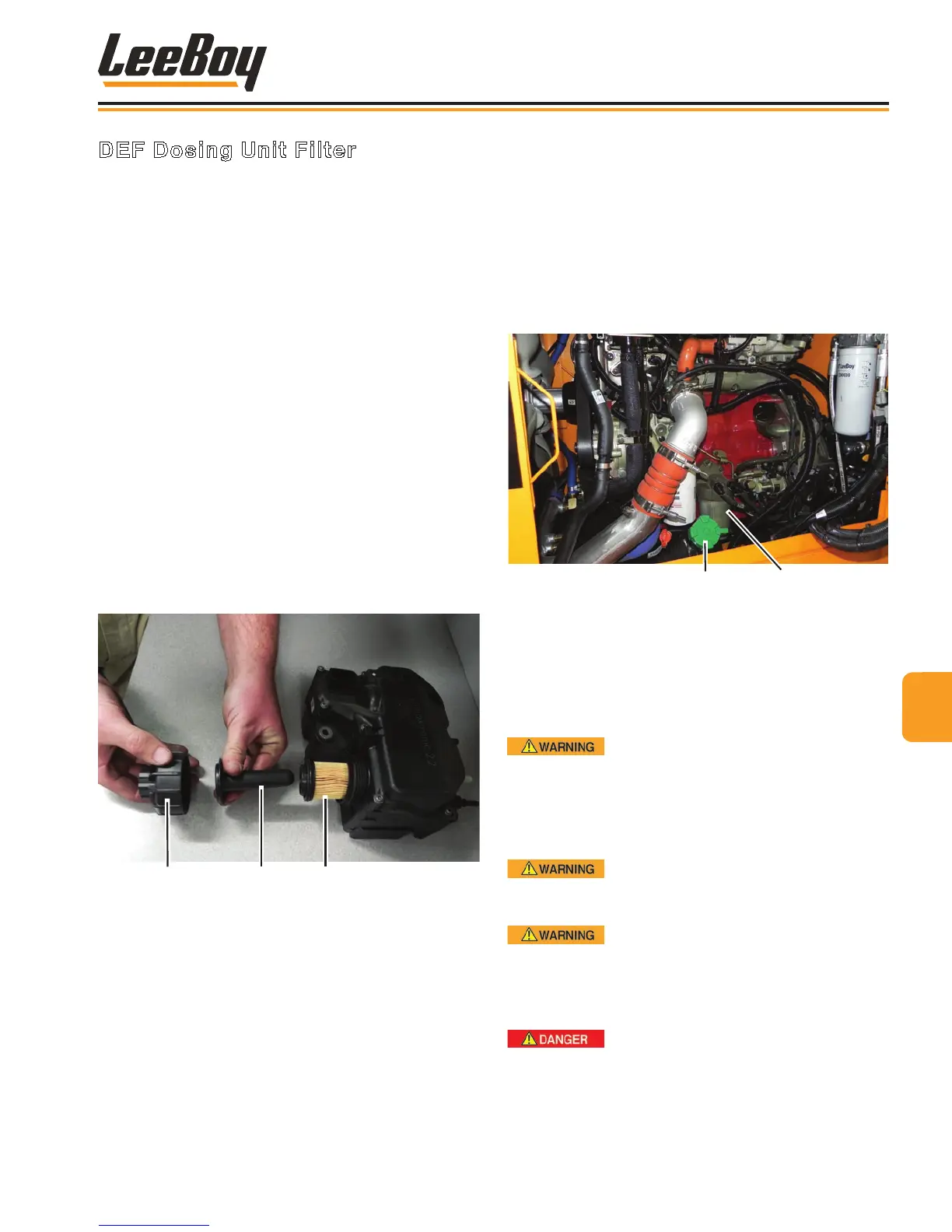

4. Unscrew the DEF lter cap and remove the

equalizing element and lter element. (Figure 5-17)

Figure 5-17. DEF Dosing Unit Filter

1 - Filter Cap

2 - Filter Equalizing Element

3 - Filter Element

5. Discard both the lter element and equalizing

element in accordance with environmental

regulations.

6. Reinstall the new lter and equalizing element.

7. Reinstall and tighten the cap.

NOTE: Lubrication on the DEF lter O-ring is not

required.

FUEL SYSTEM

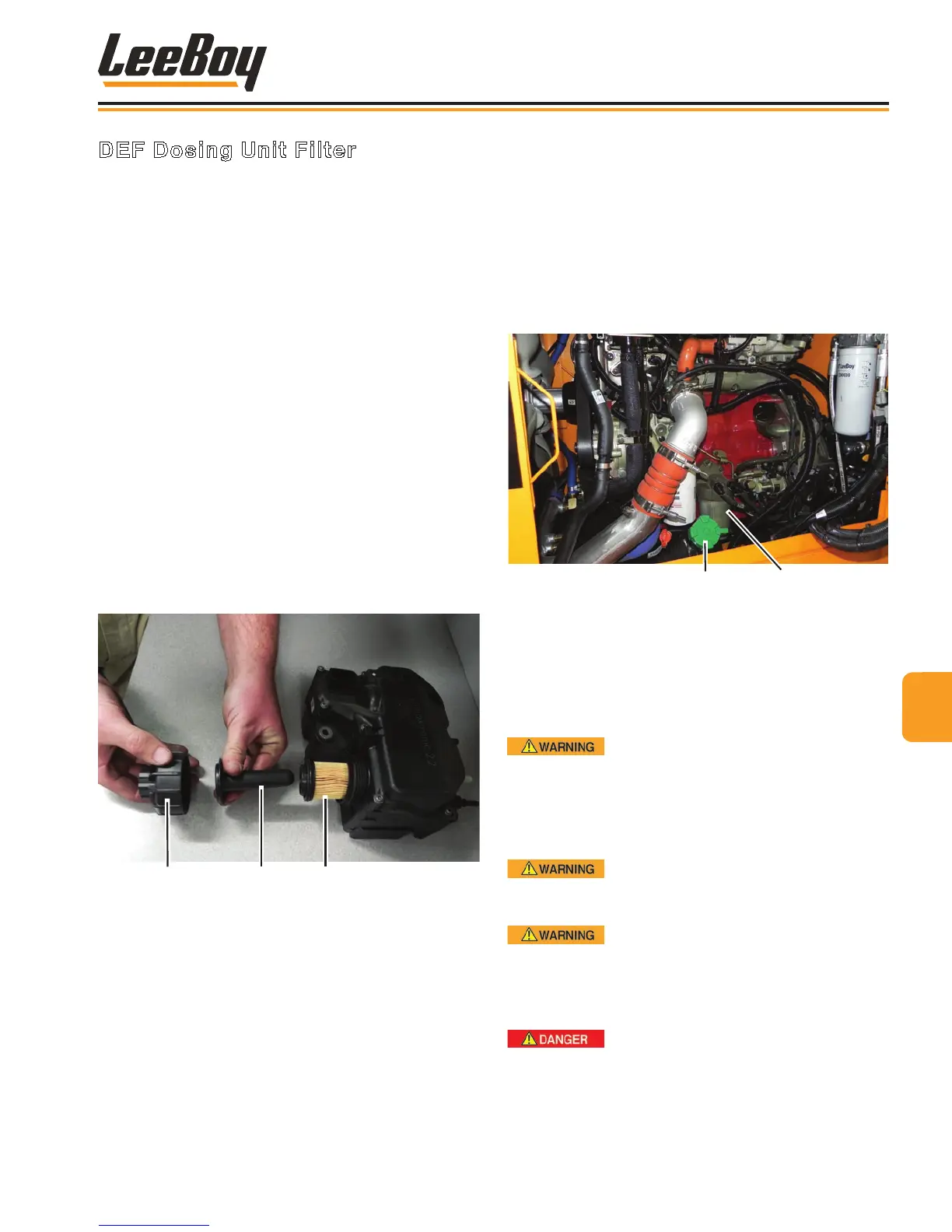

The fuel level is indicated on the PV485 digital

display component on the steering column. Proper

maintenance of the fuel system ensures top

performance and prevents damage to internal engine

components. The fuel ller cap and fuel lter are located

just inside the right engine access panel. (Figure 5-18)

The fuel water separator component is also located at

the right engine access door.

Figure 5-18. Fuel Filler Cap and Fuel Filter

NOTE: Fill the tank to FULL before storing the

motor grader overnight to reduce moisture

accumulation from condensation in the tank. Fuel

contaminated by water promotes the growth of

microbes that can clog fuel lters and lines over

time.

The operator should NEVER be on or

near the motor grader while fuel is being added. NO

SMOKING while lling the fuel tank as all fuels for

internal combustion engines are ammable. Fill the

fuel tank only in a designated area where there is

good ventilation and a re extinguisher available.

NEVER ll the tank, check fuel level

or check for fuel leaks near an open ame or near

equipment that can create sparks.

Diesel fuel is very ammable. Use

extra caution and DO NOT spill fuel. DO NOT change

the fuel lter while the motor grader is running. DO

NOT change the fuel lter in an area near an open

ame. DO NOT smoke while changing the fuel lter.

NEVER loosen a fuel injector line as

contents are under high pressure. DO NOT try to

bleed air by loosening injector lines.

5

Maintenance

LeeBoy 685D Motor Grader 5-19

Loading...

Loading...