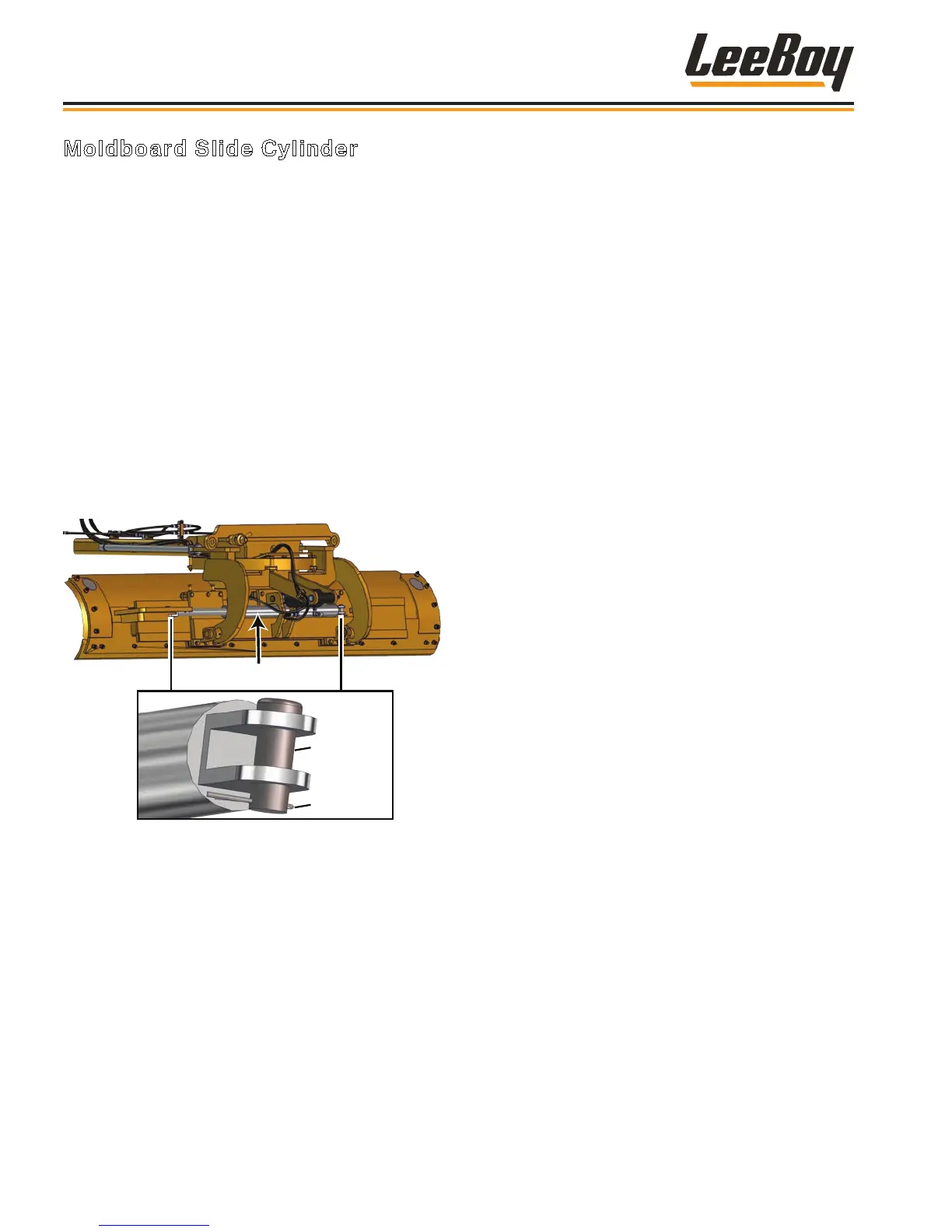

Moldboard Slide Cylinder

Hydraulic cylinders function by pressurized hydraulic

oil. The moldboard slide cylinder moves the moldboard

from side to side. Extensive wear or damage to

the cylinder could cause leaks, resulting in loss of

pressure that adversely affects performance. If you

notice hydraulic oil leaking on the moldboard or loss of

functionality, check the hydraulic hoses and ttings rst.

If the moldboard slide cylinder needs to replaced:

1. Park the grader on a level surface in a designated

area where oil does not touch or run off onto the

ground.

2. Engage the park brake and place wheel chocks on

wheels for safety.

3. Extend the moldboard left to its limit.

4. Remove the cotter pin, then the cylinder pin on the

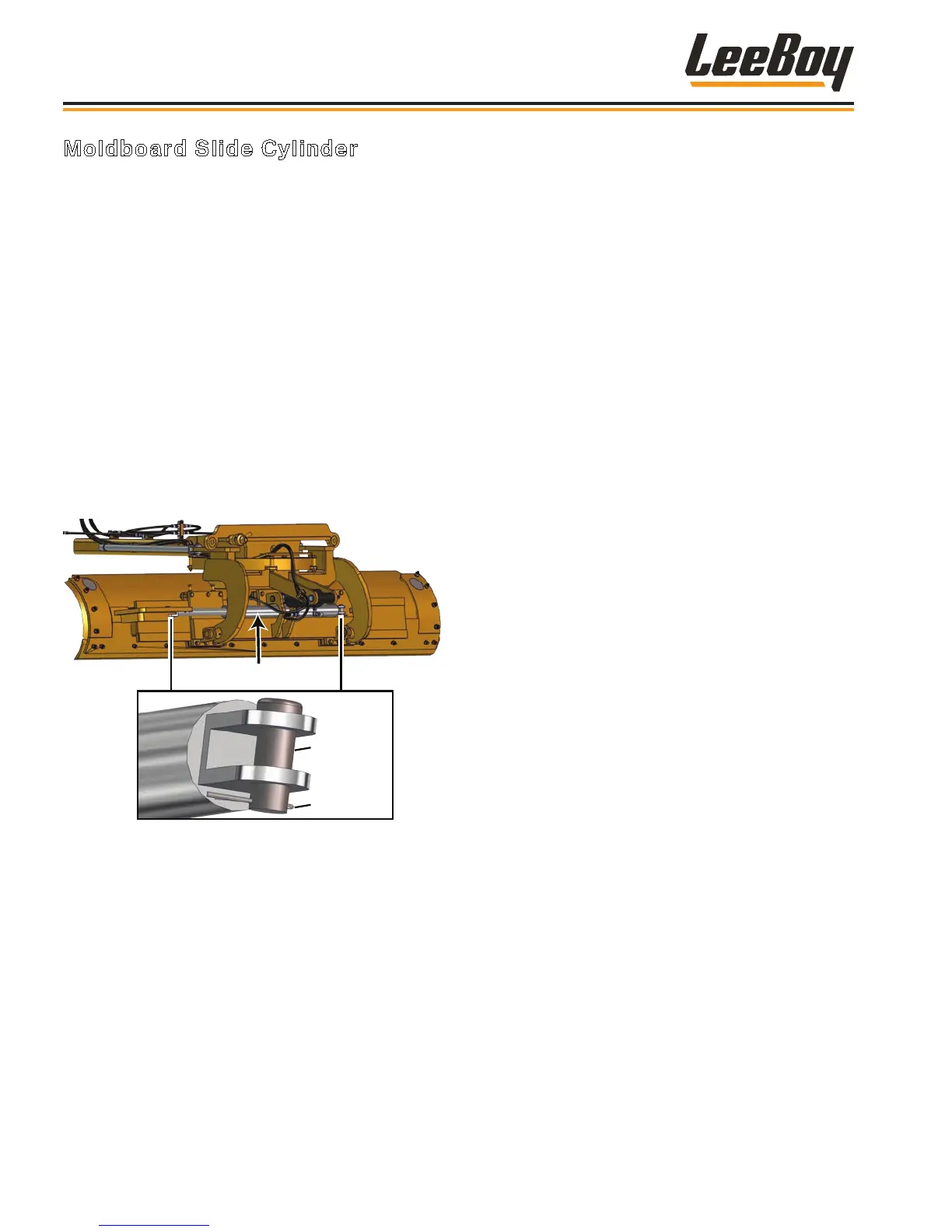

left side of the slide cylinder. (Figure 5-40)

Cotter Pin

Slide Cylinder

Cylinder

Pin

Figure 5-40. Moldboard Slide Cylinder

5. Retract the moldboard and shut down the engine.

6. Disconnect, plug and tag the hydraulic hoses, being

very careful to prevent any contamination when

plugging the hydraulic hose ttings.

NOTE: Inspect the hydraulic ttings. Replace any

damaged or worn ttings.

7. Place a block or other means of supporting the

cylinder, then remove the cotter pin and cylinder

pin from the right side. Carefully slide the cylinder

away from the moldboard support frame to remove

it. Clean the area thoroughly before installing new

cylinder.

8. Position the new moldboard slide cylinder into

place.

9. Insert the cylinder pin on the stationary side rst,

then reconnect that hydraulic hose. Start the grader

and extend the cylinder rod to align it through the

mounting hole.

10. Reinstall cylinder and cotter pins on each side of

the cylinder. (It is recommended that you use new

cotter pins.)

11. Reconnect the hydraulic hoses according to the

tags for correctly reinstalling hoses.

12. Using a grease gun, lubricate the cylinder rod (left

side).

13. Start the engine and idle for a few minutes to ensure

the hydraulic oil has warmed in the system.

14. Extend and retract the moldboard several times to

ensure proper operation and check for leaks.

Maintenance

LeeBoy 685D Motor Grader5-34

Loading...

Loading...