General information

The Lexmark

TM

MS310d and MS310dn are single‑function monochrome laser printers designed for small and

mid‑sized workgroups. All information in this service manual pertains to all models unless explicitly noted.

The printers are available in the following models:

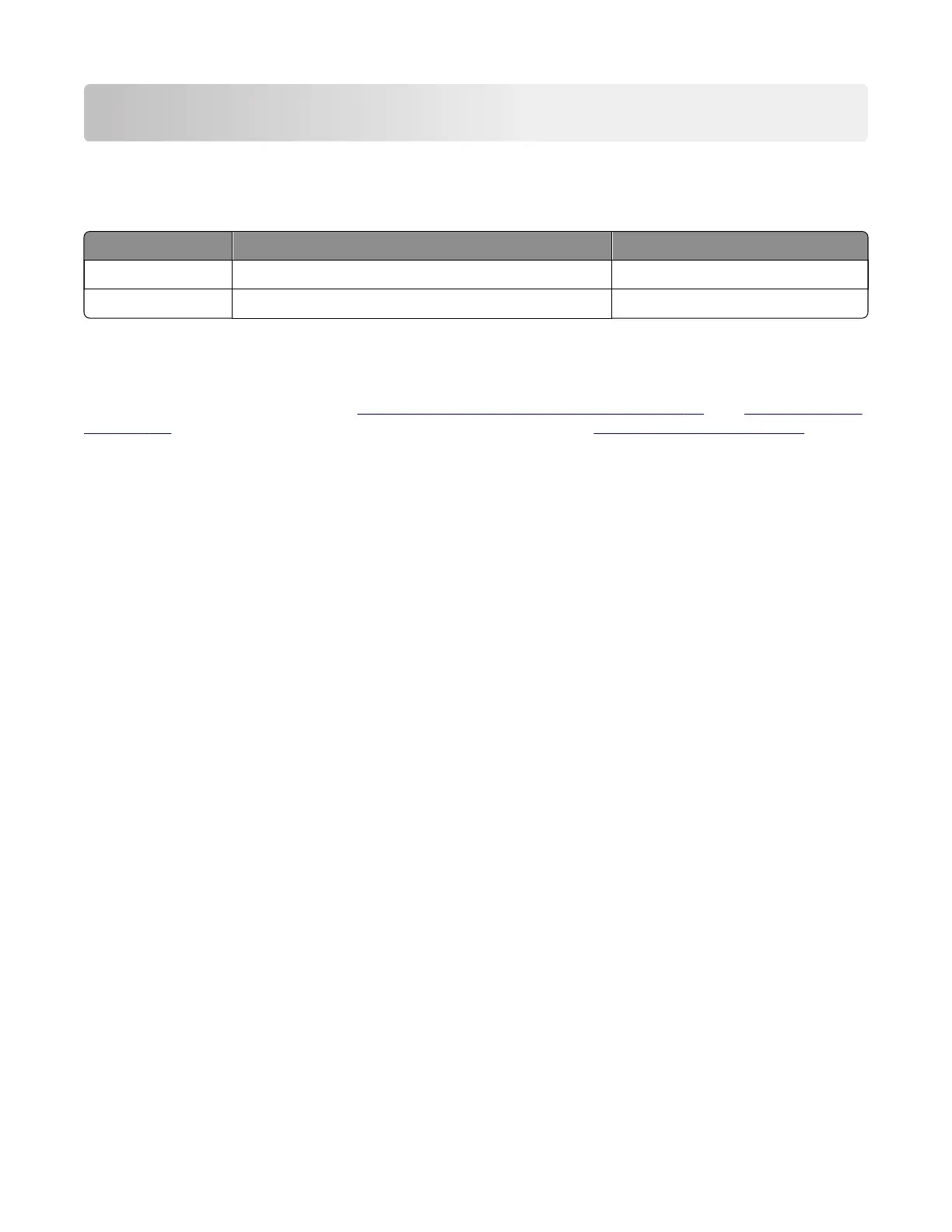

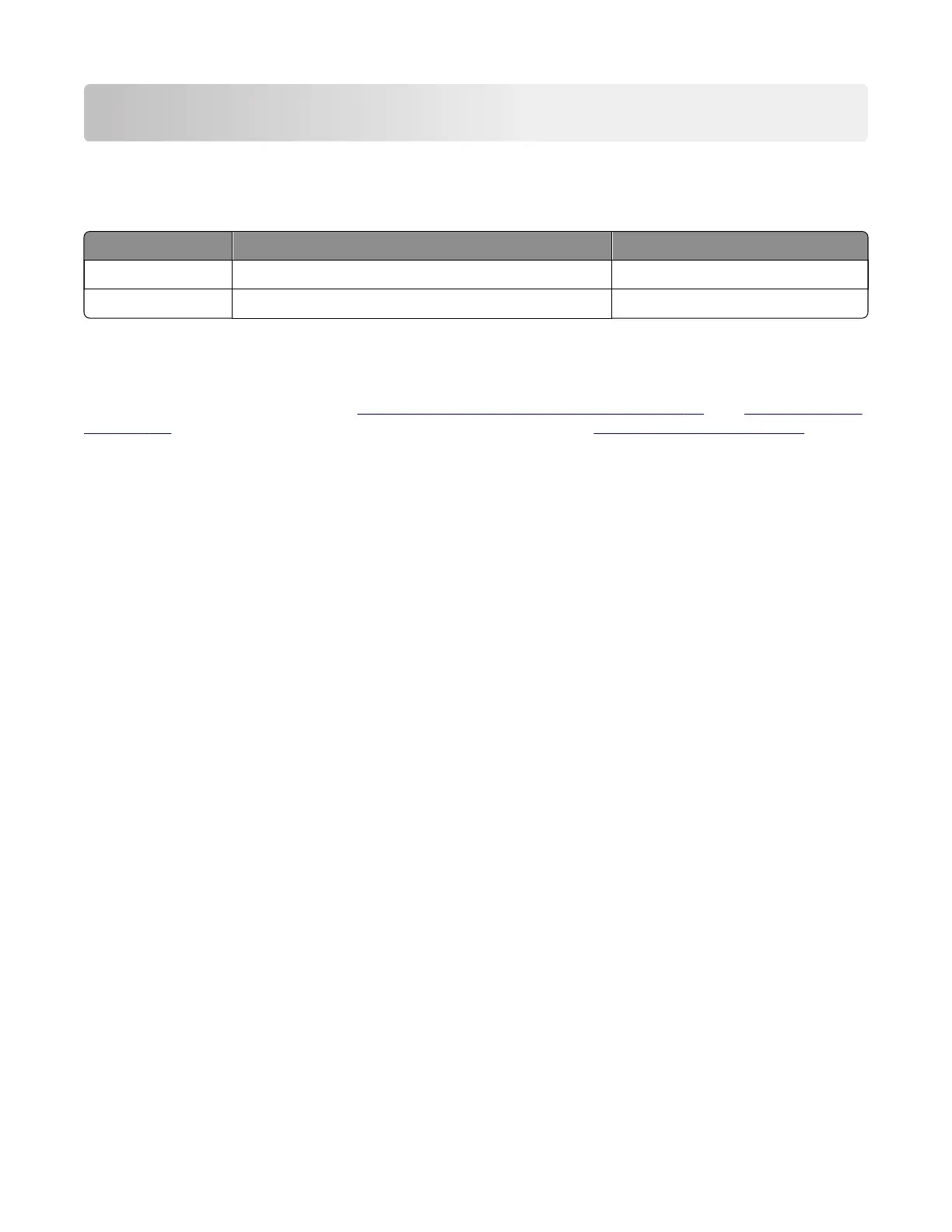

Model Configurations Machine type / model

MS310d Duplex printer 4514‑220

MS310dn Duplex printer, network capable 4514‑230

The diagnostic information in this manual leads you to the correct

field

replaceable unit (FRU) or part. Use the

error code charts, symptom index, and service checks to determine the symptom and then repair the failure.

After you complete the repair, perform tests as needed to verify the repair.

To begin diagnosing a problem, go to

“Diagnostics and troubleshooting” on page 35. See “Parts removal”

on page 171 for information about removing and reinstalling parts. See “Parts catalog” on page 278 to help

identify parts.

Media guidelines

Paper guidelines

Selecting the correct paper or specialty media reduces printing problems. For the best print quality, try a sample

of the paper or specialty media before buying large quantities.

Paper characteristics

The following paper characteristics

aect

print quality and reliability. Consider these characteristics when

evaluating new paper stock.

Weight

The standard printer trays can automatically feed paper weights up to 90‑g/m

2

(24‑lb) bond grain long paper.

The optional trays can automatically feed paper weights up to 120‑g/m

2

(32‑lb) bond grain long paper. The

multipurpose feeder can automatically feed paper weights up to 163‑g/m

2

(43‑lb) bond grain long paper. Paper

lighter than 60 g/m

2

(16 lb) might not be sti enough to feed properly, causing jams. For best performance, use

75‑g/m

2

(20‑lb) bond grain long paper. For paper smaller than 182 x 257 mm (7.2 x 10.1 inches), it is recommended

to use 90 g/m

2

(24 lb) or heavier paper.

Note: Two‑sided printing is supported only for 60–90‑g/m

2

(16–24‑lb) bond paper.

Curl

Curl is the tendency for paper to curl at its edges. Excessive curl can cause paper feeding problems. Curl can

occur after the paper passes through the printer, where it is exposed to high temperatures. Storing paper

unwrapped in hot, humid, cold, or dry conditions, even in the trays, can contribute to paper curling prior to

printing and can cause feeding problems.

4514-2xx

General information

25

Loading...

Loading...