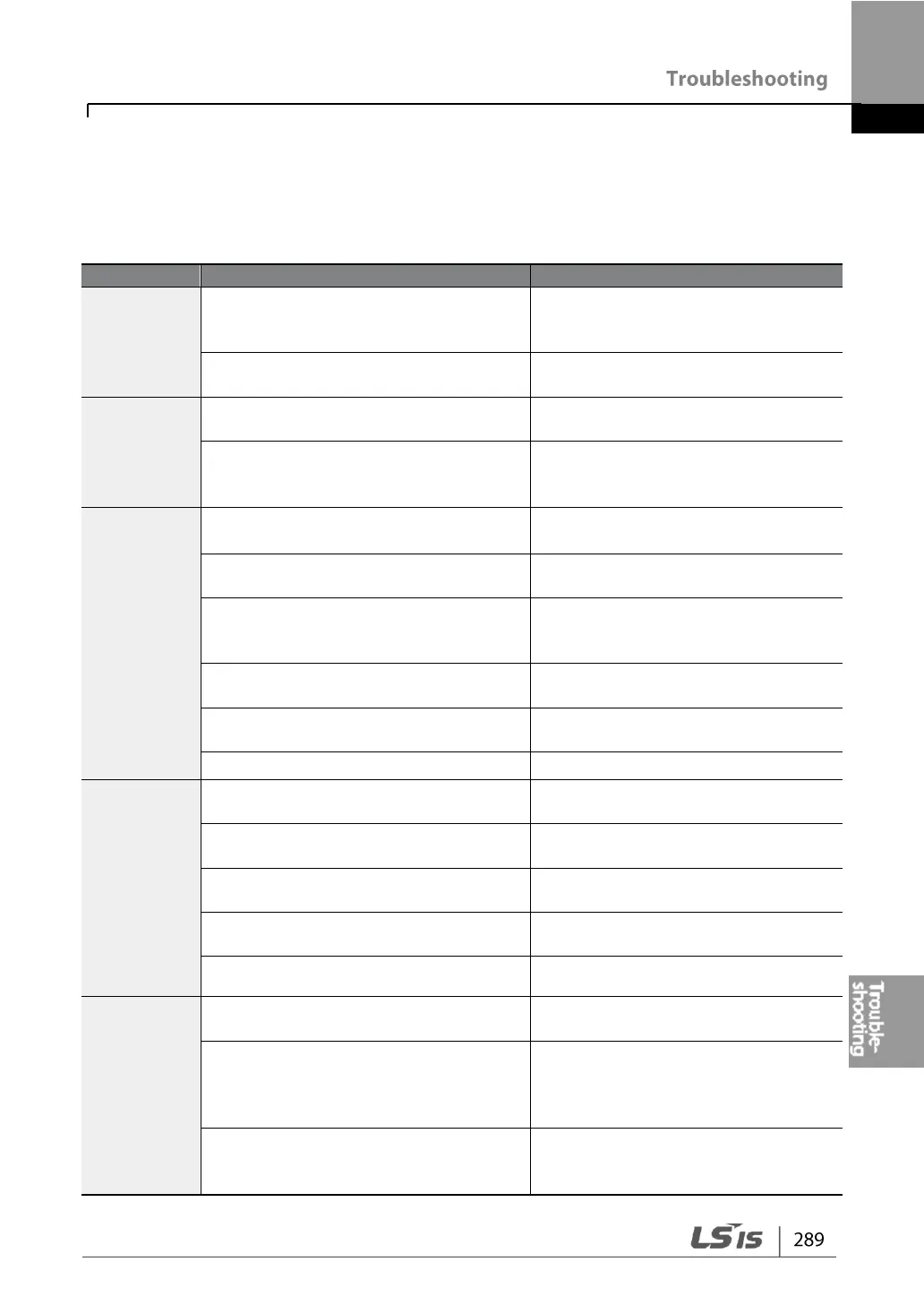

9.2 Troubleshooting Fault Trips

When a fault trip or warning occurs due to a protection function, refer to the following

table for possible causes and remedies.

The load is greater than the motor’s

rated capacity.

Replace the motor and inverter with

models that have increased

capacity.

The set value for the overload trip

level (Pr.21) is too low.

Increase the set value for the

overload trip level.

There is a motor-load connection

problem.

Replace the motor and inverter with

models with lower capacity.

The set value for underload level

(Pr.29, Pr.30) is less than the

system’s minimum load.

Reduce the set value for the

underload level.

Acc/Dec time is too short, compared

to load inertia (GD2).

The inverter load is greater than the

rated capacity.

Replace the inverter with a model

that has increased capacity.

The inverter supplied an output while

the motor was idling.

Operate the inverter after the motor

has stopped or use the speed

search function (Cn.60).

The mechanical brake of the motor is

operating too fast.

Check the mechanical brake.

A ground fault has occurred in the

inverter output wiring.

The motor insulation is damaged.

Deceleration time is too short for the

load inertia (GD2).

Increase the deceleration time.

A generative load occurs at the

inverter output.

The input voltage is too high.

Determine if the input voltage is

above the specified value.

A ground fault has occurred in the

inverter output wiring.

The motor insulation is damaged.

The input voltage is too low.

Determine if the input voltage is

below the specified value.

A load greater than the power

capacity is connected to the system

(e.g., a welder, direct motor

connection, etc.).

Increase the power capacity.

The magnetic contactor connected to

the power source has a faulty

connection.

Replace the magnetic contactor.

Loading...

Loading...