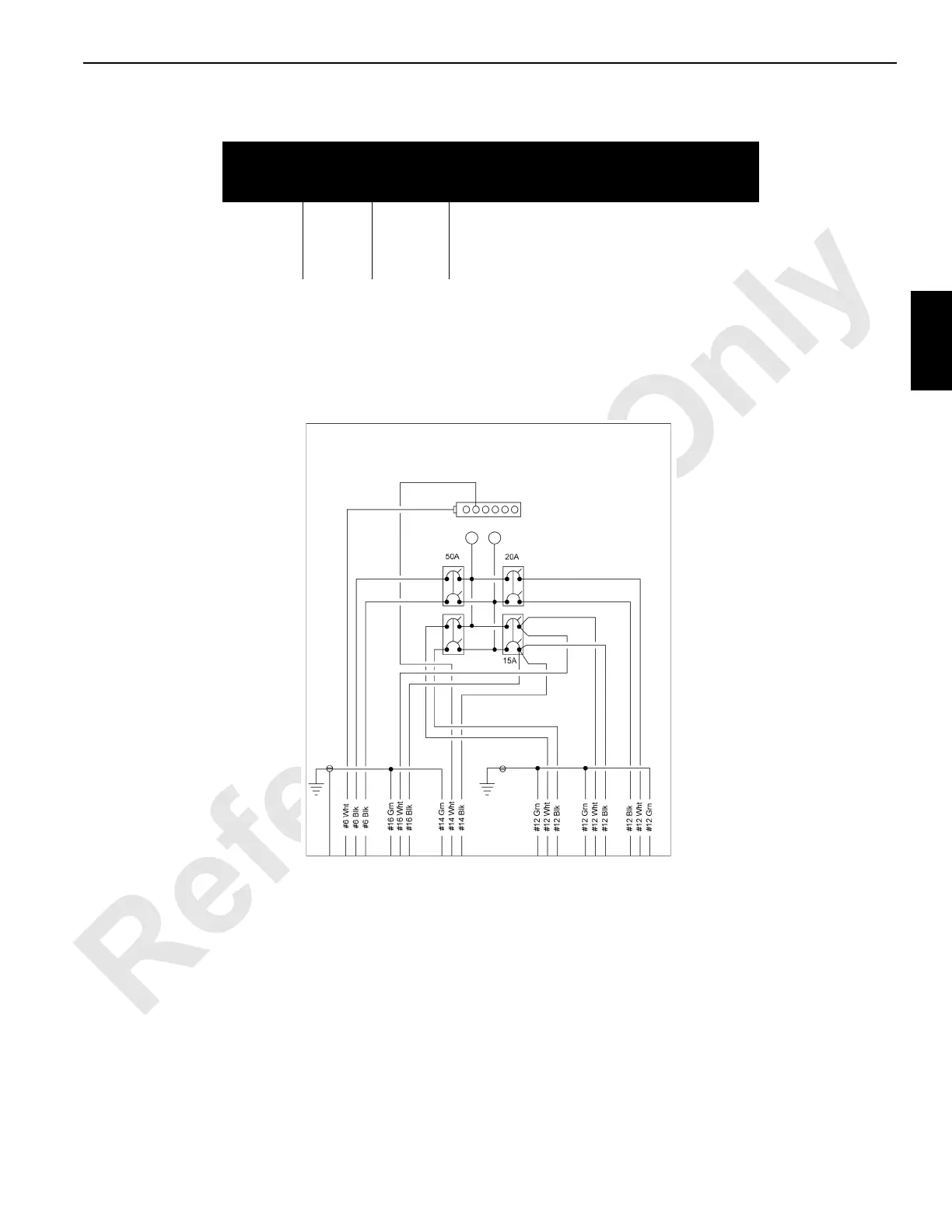

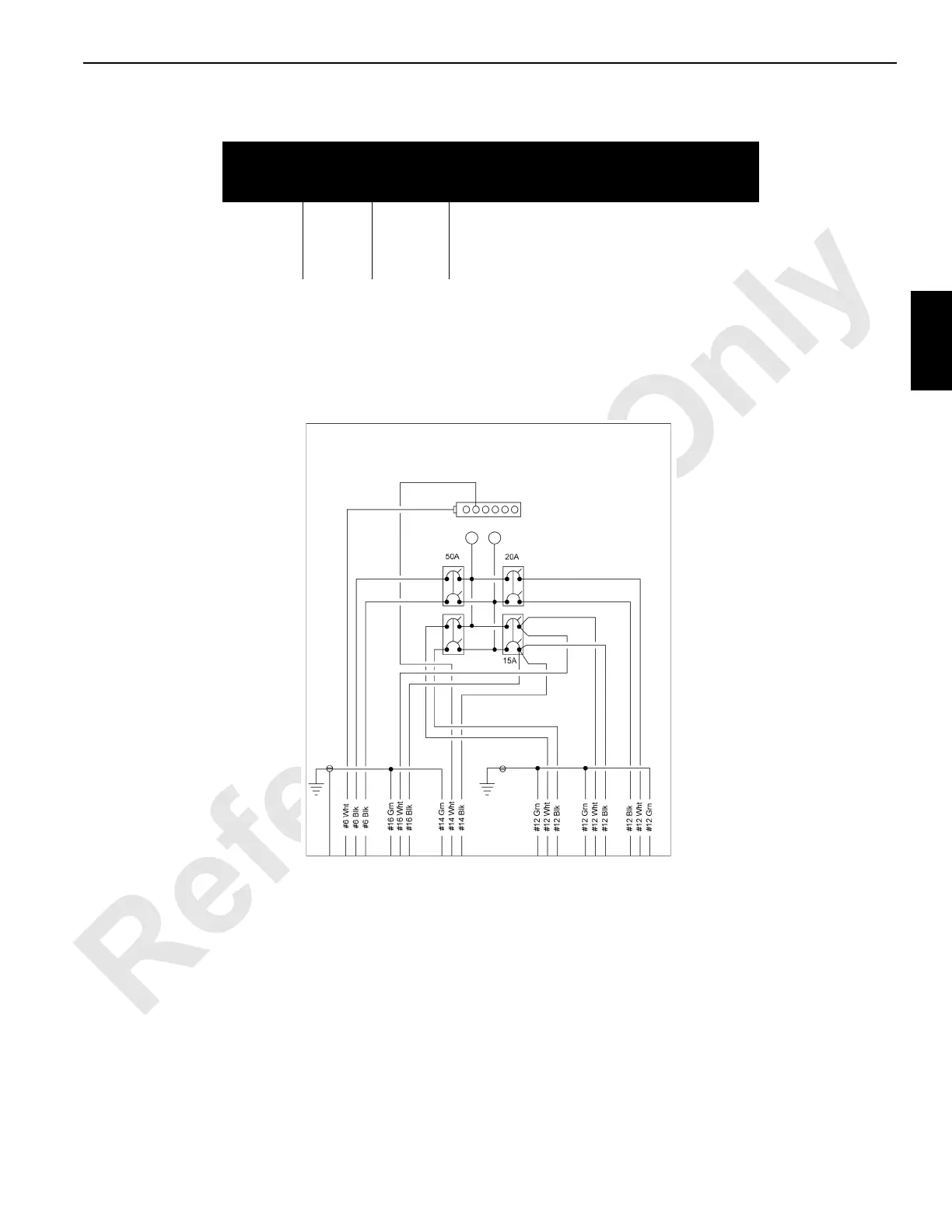

Circuit

Breaker

Amps Wire No. Description of Items Protected

Air Conditioner & Heater Assembly Fuses

A0A8CB2 15 8 HP

ECM/Power Interface Module, Cab Temp

Sensor, Blower Motor, Evaporator Thermostat,

Electric Water Valve

A0A8CB3 15 8W Front Wiper, Overhead Wiper

A17735_3

FIGURE 3-4

Loading...

Loading...