Manitowoc Published 05-09-17, Control # 014-28 1-13

16000 SERVICE/MAINTENANCE MANUAL INTRODUCTION

GENERAL OPERATION

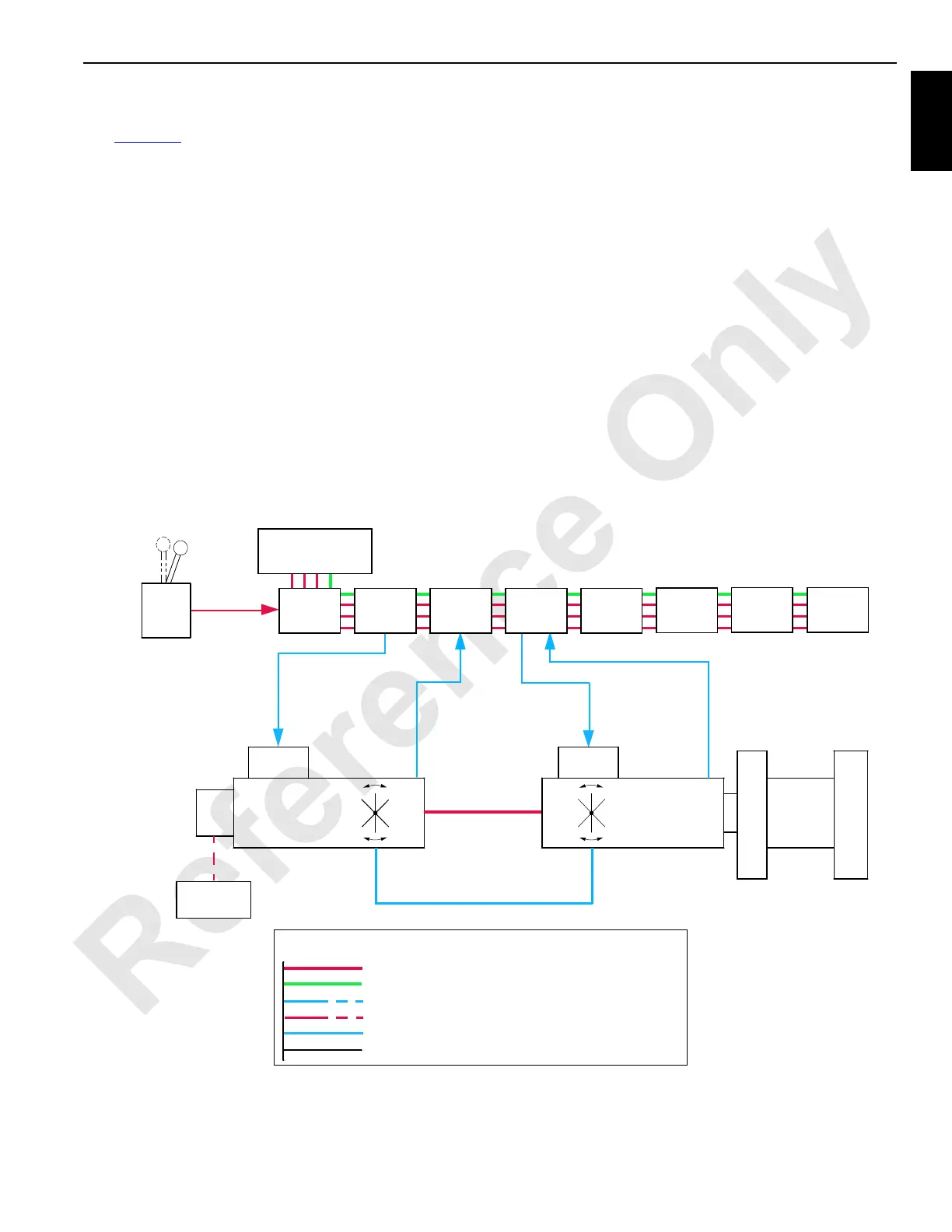

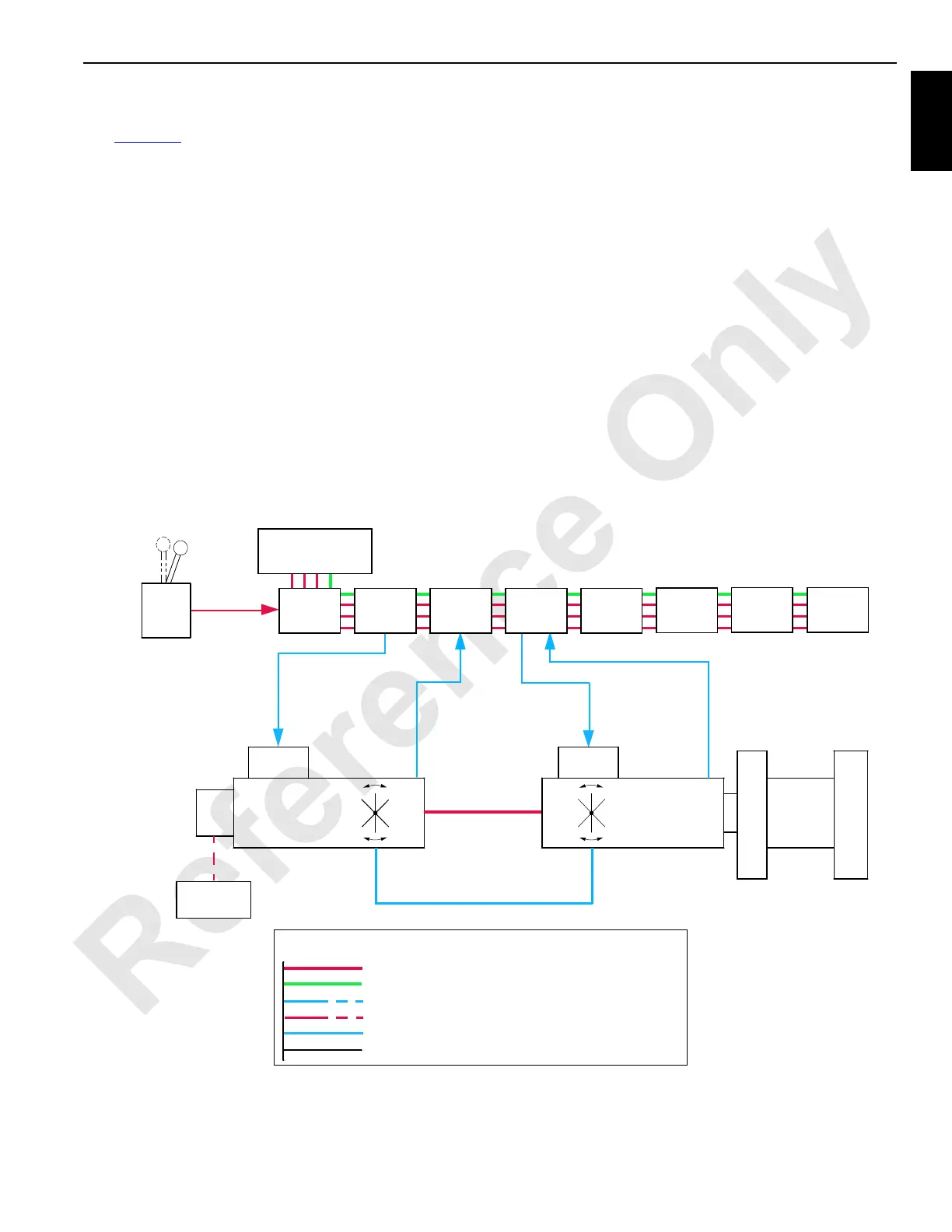

See Figure 1-8 for the following procedure.

This section describes the standard and optional equipment

available for Model 16000 crane. Disregard any equipment

your crane does not have.

The operating system is an EPIC

(Electrical Processed

Independent Control) with CAN-bus (Controller Area

Network) technology. The CAN-bus system uses multiple

nodes that contain remote controllers. The remote node

controllers communicate with Node-1 master controller by

sending information data packets over a two-wire BUS line.

The data packets are tagged with addresses that identify

each system component.

With the CAN-bus system, the independently powered

pumps, motors, and cylinders provide controller driven

control logic, pump control, motor control, on-board

diagnostics, and service information. Crane information is

shown on main display in operator’s cab (see Main Display in

Section 3).

A diesel engine provides power to operate system pumps

through a pump drive transmission. In a closed-loop

hydraulic system, high-pressure hydraulic fluid from the

system pump drives a hydraulic motor or cylinder. Pressure

develops within the closed-loop system while resistance to

movement of the load on motor or cylinder is overcome.

When movement begins, pump volume displacement

maintains motor speed or cylinder movement. The spent

hydraulic fluid from the motor outlet returns to pump input.

The crane closed loop systems are swing, right travel, left

travel, boom/mast hoist, and load drums.

Enabled means hydraulic fluid can flow in a system or

electrical component is on. Disabled means hydraulic fluid

is blocked in a system or electrical component is off. Each

hydraulic solenoid valve is assigned an HS number for

identification in this section.

FIGURE 1-8

Control Signal

(Pump Stroke)

Control

Handle

Pressure

Feedback

Node 2

Motor Speed

Feedback

Node 1

Master Controller

Handle

Command

Signal

Swashplate

Position

Control Signal

(Motor Stroke)

Hydraulic

Motor

Suction

Manifold

Charge

Pump

High Pressure

Side

Low Pressure Side

Hydraulic

Piping

Node 3 Node 4 Node 5

Node 20 Node 21

Electronic

Displacement

Control (EDC)

Pressure

Control Pilot

(PCP)

Hydraulic

Pump

Drum

Line Legend (For Colored Figures)

High-pressure Hydraulic, Positive Electrical

Negative Electrical (Ground)

Low-pressure Hydraulic, Signal Electrical

Control Or Pilot Pressure Hydraulic

Case Return Pressure Hydraulic

Not Active Line Or Circuit

Node 6

16-1001

Node 7

Loading...

Loading...