Manitowoc Published 05-09-17, Control # 014-28 1-46

16000 SERVICE/MAINTENANCE MANUAL INTRODUCTION

When front or rear rotating bed pins switch is placed in the

engage position and held, an input voltage is sent to Node-1

controller. Node-4 controller sends a 24 volt output to enable

rotating bed pins solenoid HS-40 (front selected) or HS-42

(rear) and shifts valve to the engage position. Node-3

controller sends a variable zero to 24 volt output to enable

accessory system proportional relief solenoid HS-68.

Hydraulic fluid pressure at approximately 3,000 psi (207 bar)

flows to rotating bed pins accessory valve. Hydraulic fluid

leaves the accessory valve and enters piston end of selected

pin cylinders, extending cylinder rod to engage the rotating

bed pins. Hydraulic fluid from rod end of pin cylinders leaves

accessory system valve and returns to tank. When rotating

bed pins switch is released, valve returns to center position.

When rotating bed pins switch is placed in the disengage

position and held, an input voltage is sent to Node-1

controller. Node-6 controller sends a 24 volt output to enable

selected front or rear pins solenoid HS-41 (front) or HS-43

(rear) and shifts valve to the disengage position. Node-3

controller sends a variable zero to 24 volt output to enable

accessory system proportional relief solenoid HS-68.

Hydraulic fluid pressure at approximately 3,000 psi (207 bar)

flows to rotating bed pins accessory valve. Hydraulic fluid

leaves the accessory valve and enters rod end of pin

cylinders, retracting cylinder rods to disengage the rotating

bed pins. Hydraulic fluid from piston end of pin cylinders

leaves accessory system valve and returns to tank. When

rotating bed pins switch is released, solenoid HS-41 (front) or

HS-43 (rear) returns to center position. Node-3 controller

sends a variable zero to 24 volt output to disable accessory

system proportional relief solenoid HS-68.

Rigging Winch (Drum 0)

See Figure 1-35, Figure 1-40, and Figure 1-41 for following

procedure.

The rigging winch (Drum 0) is located in the boom butt.

During normal operation the rigging winch solenoid is motor

spooled where both cylinder ports and tank port of valve

spool section are connected in center position. When an

accessory valve spool shifts, supply flow to the other

accessory valves is limited. The accessory system pressure

sender monitors accessory system pressure.

Access rigging winch enable screen from desired system

drum Function Mode screen. When rigging winch screen is

enabled, the computer selects the handle to operate rigging

winch. The computer selected handle display light is 0.

When selected rigging winch control handle is moved

forward in pay out position, Node-4 controller sends a 24

volt output to enable rigging winch pay out solenoid HS-55

and shifts valve to the pay out position. Node-3 controller

sends a variable zero to 24 volt output to enable accessory

system proportional relief solenoid HS-68.

When an accessory valve spool shifts, supply flow to the

other accessory valves is limited. The accessory system

pressure sender monitors accessory system pressure.

Control handle movement controls proportional relief valve

hydraulic flow to rigging winch accessory valve. Hydraulic

fluid leaves the accessory valve and enters pay out side of

winch motor to pay out wire rope. Return hydraulic fluid from

motor leaves accessory system valve and returns to tank.

When rigging control handle is moved to neutral, accessory

valve returns to center position. Node-3 controller sends a

zero volt output to disable accessory system proportional

relief solenoid HS-68.

When selected rigging winch control handle is move back to

haul in position, Node-4 controller sends a 24 volt output to

enable rigging winch pay out solenoid HS-54 and shifts valve

to the haul in position. Node-3 controller sends a variable

zero to 24 volt output to enable accessory system

proportional relief solenoid HS-68.

FIGURE 1-39

Pressure

Sender

Front Rotating

Bed Pins

Hand-Held

Wireless Remote

HS-68

HS-41

HS-40

Engine Pump

16-1031

Accessory Pump

(Low-Pressure)

HS-43

HS-42

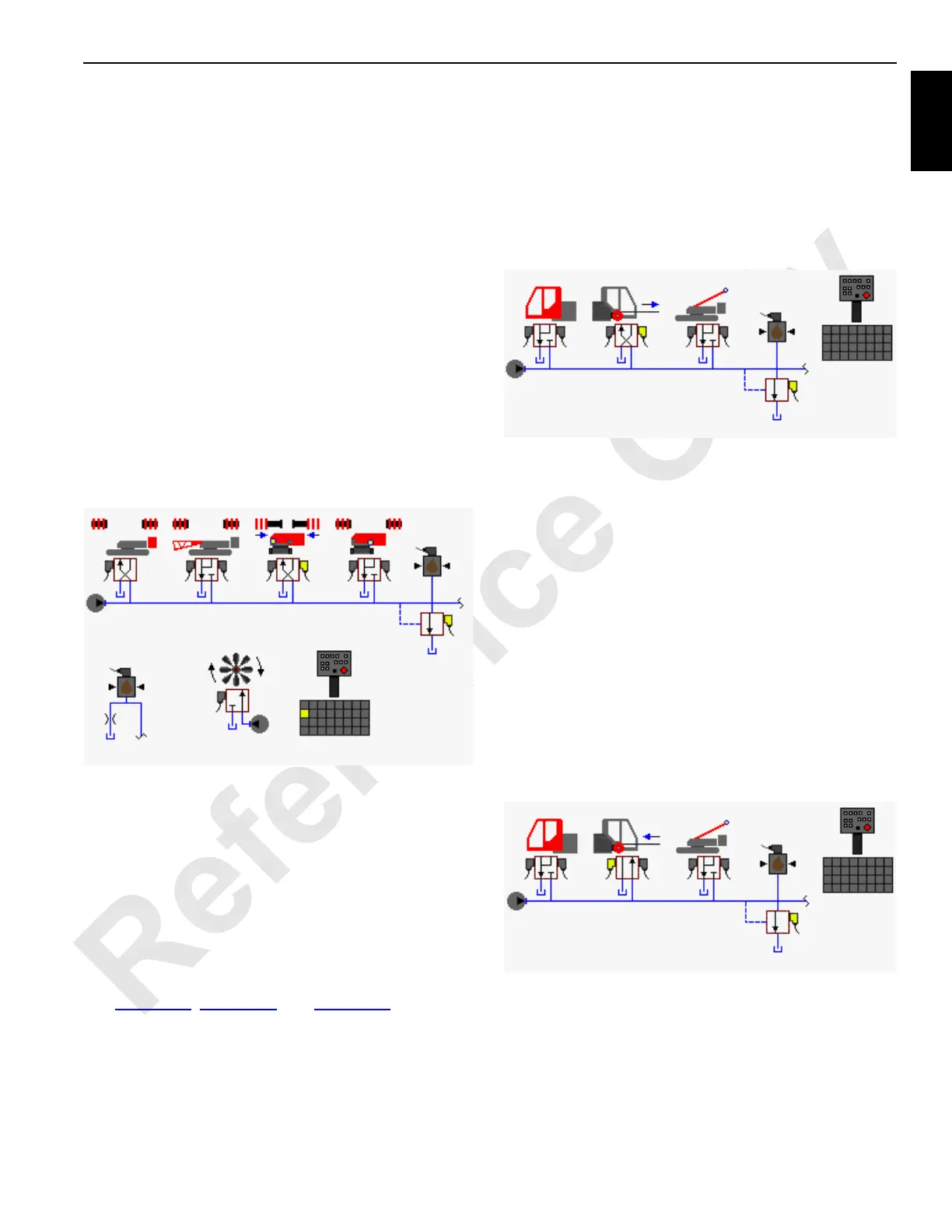

FIGURE 1-40

Pressure

Sender

Accessory

Pump

Rigging Winch

HS-68

HS-55

HS-54

16-1032

500 to 3,000 psi

(35 to 204 bar)

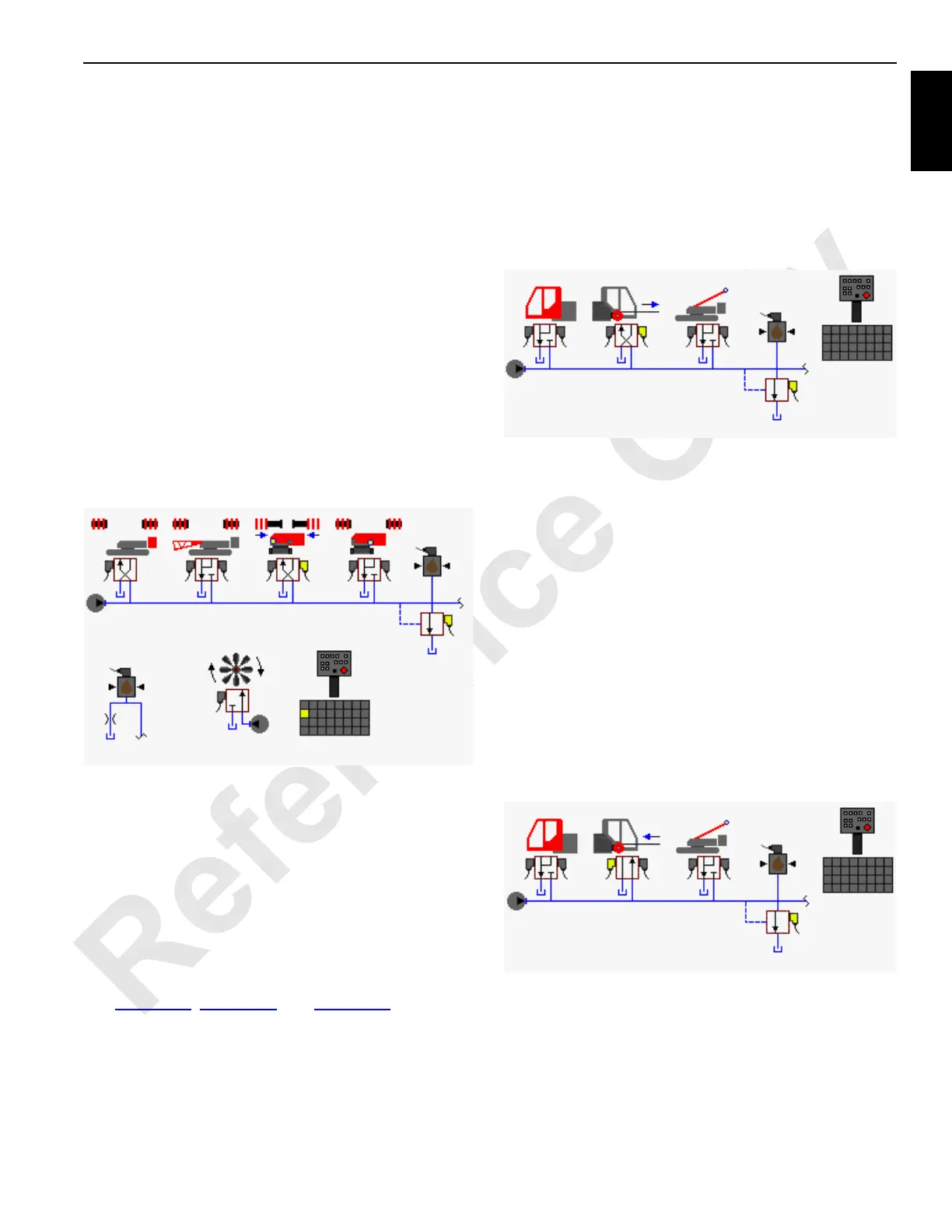

FIGURE 1-41

Pressure

Sender

Accessory

Pump

Rigging Winch

HS-68

HS-55

HS-54

16-1033

500 to 3,000 psi

(35 to 204 bar)

Loading...

Loading...