INTRODUCTION 16000 SERVICE/MAINTENANCE MANUAL

1-54

Published 05-09-17, Control # 014-28

MAX-ER 16000 DESCRIPTION OF

OPERATION

See MAX-ER Operator Manual for complete instructions.

MAX-ER Components

See Hydraulic Schematic in Section 2 of Service Manual.

The MAX-ER Attachment has a wheeled counterweight

assembly which supplements the crane’s counterweights.

Added counterweight increases the crane’s capacity and the

amount of boom it can operate while maintaining its ability to

travel and swing with and without a load.

The MAX-ER 16000 wheeled counterweight assembly

consists of the following components (see Figure 1-52

):

• Wheeled Counterweight Assembly - suspended from

a fixed mast by straps and a hydraulic lift cylinder

fastened to counterweight base. The wheeled

counterweight assembly is connected to the rear of the

crane by a telescopic beam which has three operating

positions.

• Counterweight Lifting Cylinder – suspends wheeled

counterweight assembly from the fixed mast. The lift

cylinder automatically raises and lowers the wheeled

counterweight assembly in response to changes in load

(weight of lifted load and boom angle).

• Load Sensing Pin mounted in one mast strap monitors

mast loading. The pin sends a variable input voltage to

the crane’s Node-1 controller for controlling

counterweight lift cylinder position.

• Jacking Cylinders – allows wheeled counterweight

assembly to stand alone and assists with positioning

wheels for traveling or swinging.

• Wheel Assembly – allows wheeled counterweight

assembly to travel behind crane or swing.

• Telescopic Beam Cylinder – adjustable beam that

connects wheeled counterweight assembly to the crane.

• CAN-Bus Programmable Controller – monitors and

operates the attachment’s electrical and hydraulic

systems. Automatically raises and lowers wheeled

counterweight assembly in response to signals from

load sensing pin and boom hoist control handle. See

Electrical Schematics in Section 3 of Service Manual.

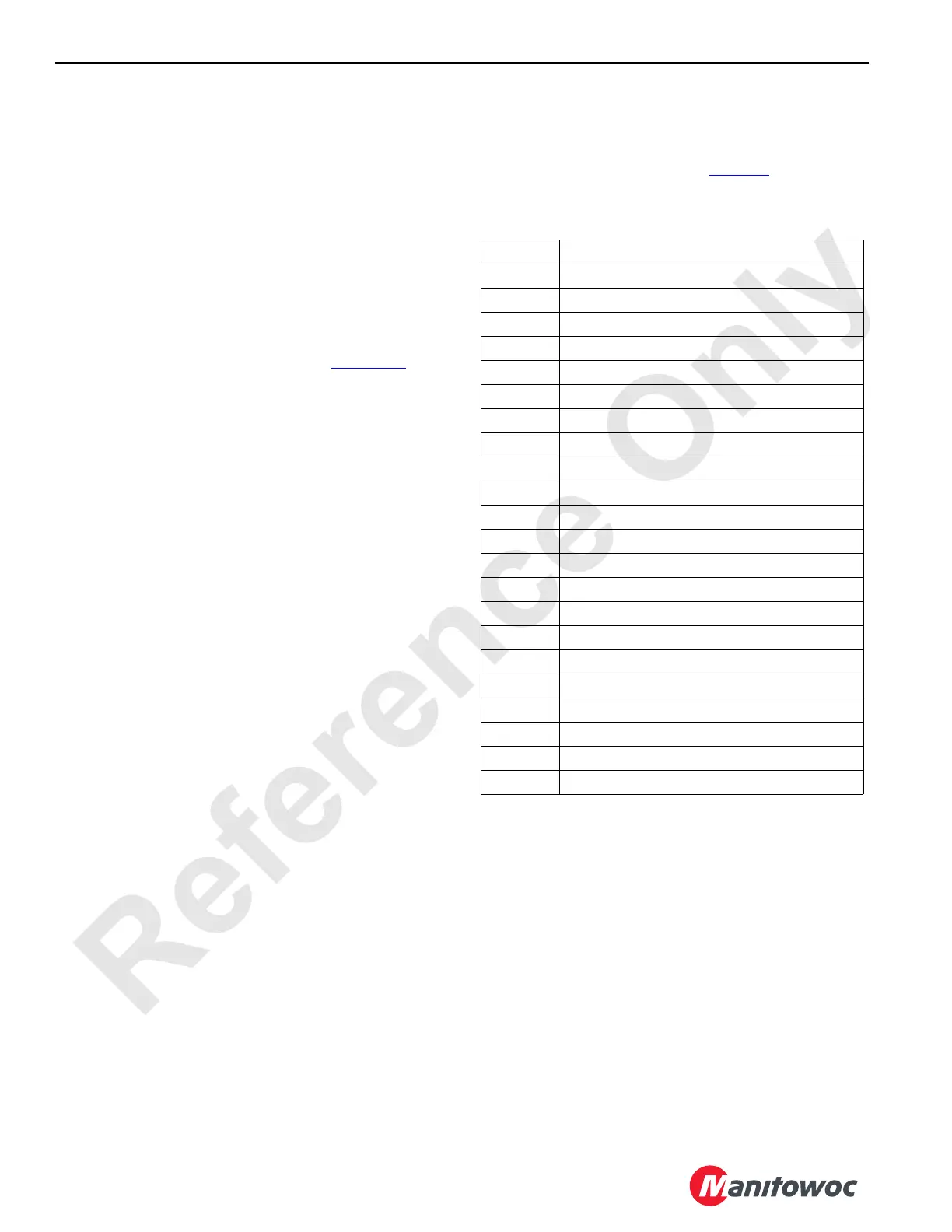

Hydraulic Solenoid Valve Identification

In this section a hydraulic system that is open means fluid

can flow in the circuit. Each hydraulic solenoid valve in this

section is assigned an HS number. Table 1-1

identifies each

hydraulic solenoid valve.

Table 1-1 Hydraulic Solenoid Valve Identification

HS-68 Accessory System Proportional Relief

HS-70 Counterweight Lift Cylinder Extend

HS-71 Counterweight Lift Cylinder Extend

HS-72 Counterweight Lift Cylinder Retract

HS-73 Counterweight Lift Cylinder Retract

HS-74 Left Front Jacking Cylinder Extend

HS-75 Left Front Jacking Cylinder Retract

HS-76 Left Rear Jacking Cylinder Extend

HS-77 Left Rear Jacking Cylinder Retract

HS-78 Right Front Jacking Cylinder Extend

HS-79 Right Front Jacking Cylinder Retract

HS-80 Right Rear Jacking Cylinder Extend

HS-81 Right Rear Jacking Cylinder Retract

HS-82 Left Wheel Steering Clockwise

HS-83 Left Wheel Steering Counter-Clockwise

HS-84 Right Wheel Steering Clockwise

HS-85 Right Wheel Steering Counter-Clockwise

HS-86 Left Wheel Brakes

HS-87 Right Wheel Brakes

HS-88 Telescopic Beam Cylinder Extend

HS-89 Telescopic Beam Cylinder Retract

HS-90 Telescopic Beam Hinge Pin In

HS-91 Telescopic Beam Hinge Pin Out

Loading...

Loading...