Manitowoc Published 05-09-17, Control # 014-28 1-15

16000 SERVICE/MAINTENANCE MANUAL INTRODUCTION

command direction. Hydraulic fluid displaced by motor

returns through hydraulic piping to inlet side of system pump.

Swashplate tilt angle determines volume of fluid that can be

pumped to the motor. Increasing swashplate tilt angle

increases piston stroke length, allowing more fluid to be

pumped to the motor. Motor servos in drum and travel

systems allow low and high speed operation.

Each pump has two multifunction valves that consist of

system relief valve and charge flow make-up check valve.

Pump system multifunction valves control maximum system

pressure and protect each pump system from damage by

limiting pressure spikes in each operating direction. When

preset loop system pressure is reached, multifunction valves

limit system pressure by de-stroking pump or transferring

fluid from high-pressure side to low-pressure side.

Charge Pressure

Charge pressure in each closed-loop system is preset at

approximately 350 psi (24 bar) with a relief valve in charge

pump. Charge pressure must be at preset value as lower

pressures can cause a slowing or stopping of operation. If

the charge pressure is set too high, the hydraulic system

could be damaged. When a system control handle is in

neutral the main display indicates system charge pressure.

If any charge pressure system drops, the system brake

begins to apply at approximately 200 psi (14 bar). Main

system pumps de-stroke as charge pressure drops to

minimum pressure. The accessory pump de-strokes if the

suction side pressure drops below 160 psi (11 bar).

Hydraulic Motors

See hydraulic motor manufacturer’s Service Manual for a

complete description of a hydraulic piston motor.

Variable displacement low torque/high speed, bent axis

piston hydraulic motors are used in the travel, boom/mast

hoist, and load drum systems. The swing system motor is a

fixed displacement, low torque/high speed, bent axis piston

hydraulic motor. Each motor contains a cylinder block,

pistons, output shaft, and internal flushing valve. Boom/mast

hoist and load drums motors have a PCP (Pressure Control

Pilot) valve that controls output speed/torque of the motor.

Motor cylinder block axis is tilted at an angle to output shaft

with pistons fitted axially around its axis. The internal end of

output shaft has a large flange face similar to pump

swashplate. The motor piston ends are connected to output

flange face and do not ride around the axis of rotating flange

face like the pump pistons.

Hydraulic fluid from pump enters selected inlet side of motor

and places a force against pistons. The retained piston ends

place a thrust against output flange with a rotational torque

that turns output shaft. This also rotates the cylinder block on

bent axis, while tilt angle to flange face moves the pistons as

they rotate. Hydraulic fluid displaced by the motor pistons,

exits motor and returns to inlet side of system pump through

hydraulic piping.

Pressure Monitoring

The main display indicates the selected system pressures.

The system pressure displayed is charge pressure or

greater. System pressure can also be checked at each

pressure sender diagnostic coupler with a 10,000 psi

(690 bar) high pressure gauge, when that system pump is

stroked.

Basic Operation

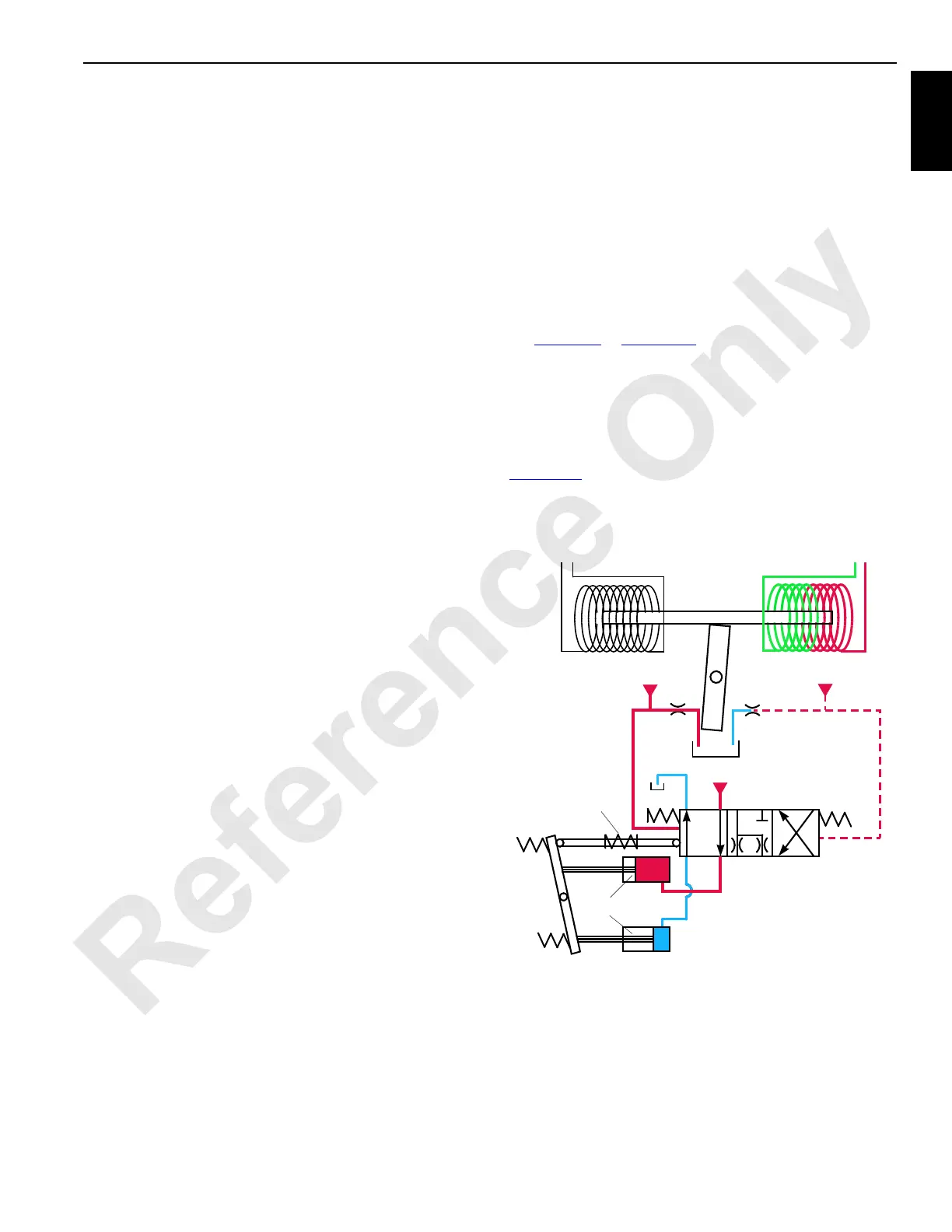

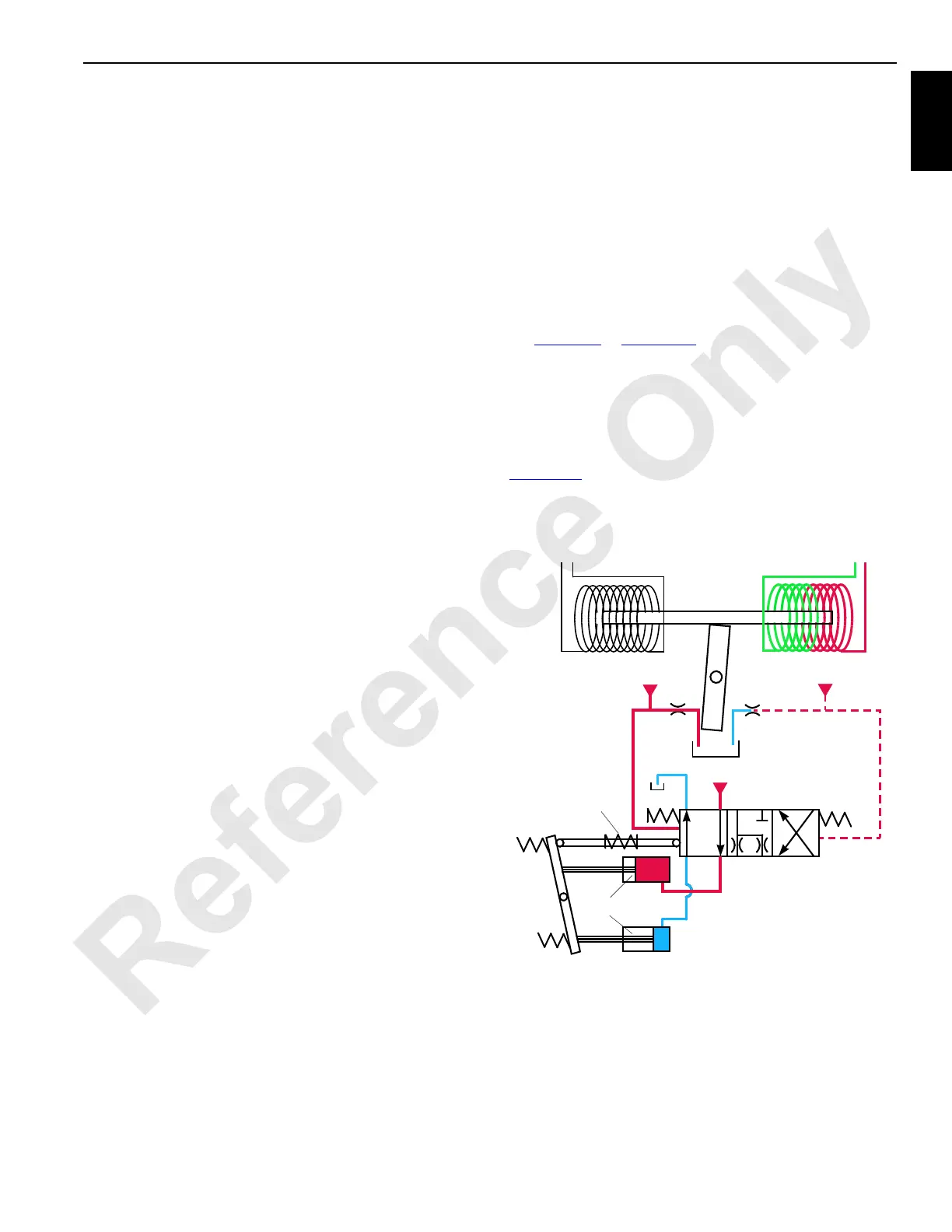

See Figure 1-9 or Figure 1-10 for the following procedure.

When a control handle is moved from neutral, an input

voltage in the handle command direction is sent to Node-1

controller. The selected component node controller sends a

variable 0 to 24 volt output that is divided by a resistor and

applied to pump external EDC (Electrical Displacement

Control). The output current magnetizes an armature

(Figure 1-9

) and starts to block one of the orifice ports,

depending on command direction.

Blockage of flow at exhaust side of right orifice port causes a

pressure difference across spool. This pressure difference

overcomes the resistance of spool spring and moves the

spool proportionally to pressurize top servo pistons. The fluid

from bottom servo pistons is routed to tank. This tilts the

swashplate, stroking the pump in selected command

direction. As swashplate tilts, chamber spring is pulled in the

FIGURE 1-9

Spool

Pilot Pressure

Control Voltage

From Controller

Pilot Pressure

Pilot Pressure

Orifice

Port

Orifice

Port

Spool

Spring

Swashplate

Servo Pistons

Armature

Modulation

Spring

Control Voltage

From Controller

16-1002

Loading...

Loading...