INTRODUCTION 16000 SERVICE/MAINTENANCE MANUAL

1-26

Published 05-09-17, Control # 014-28

TRAVEL SYSTEM OPERATION

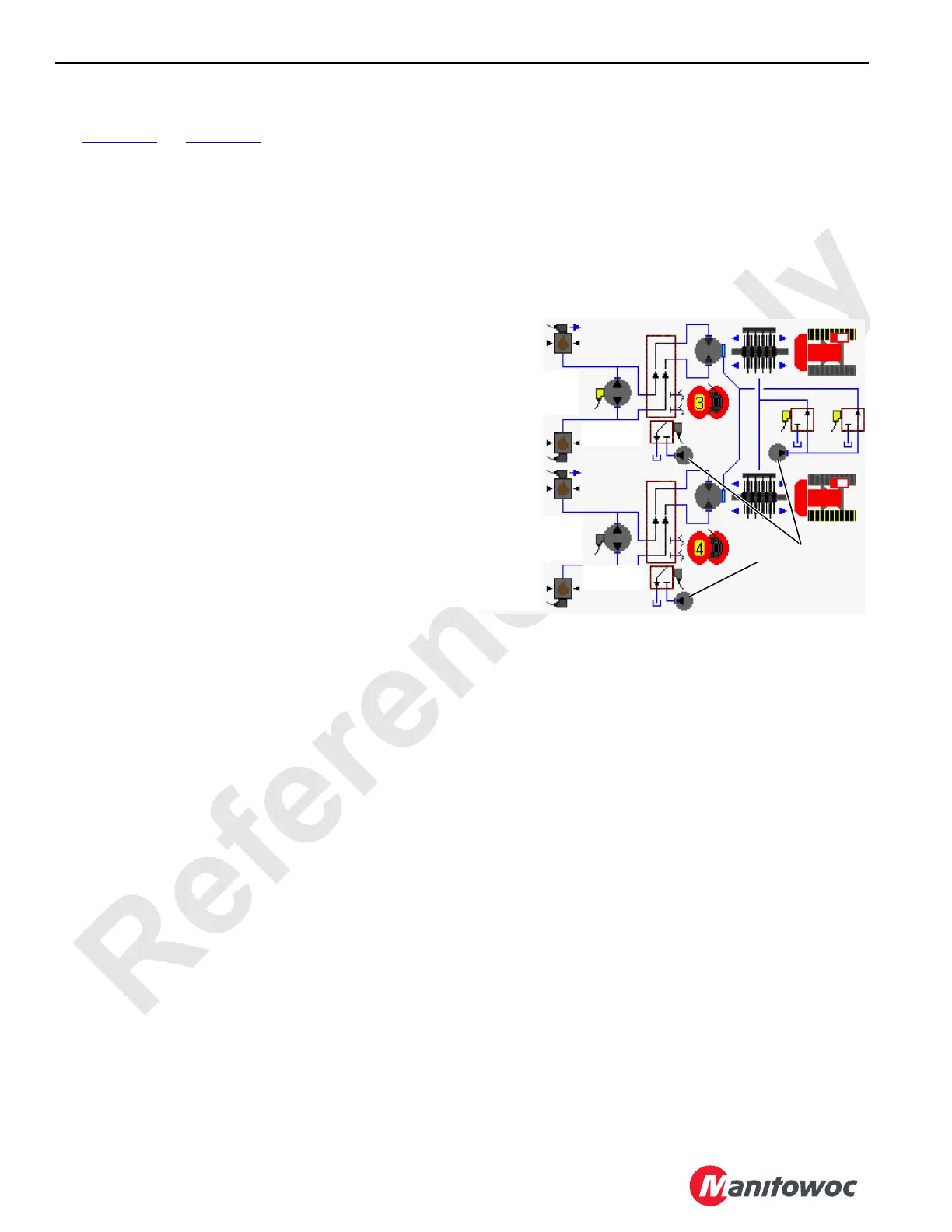

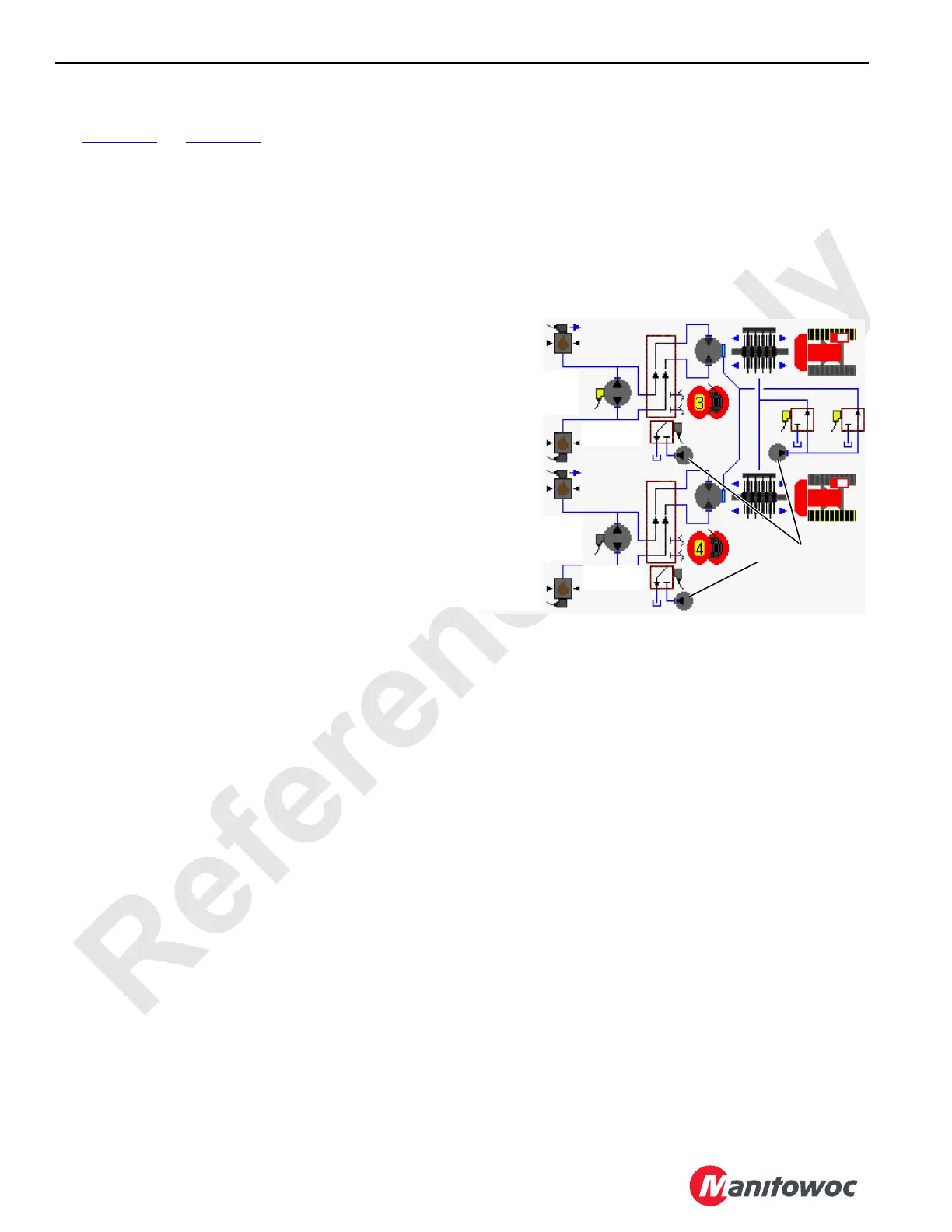

See Figure 1-18 and Figure 1-19 for the following procedure.

Each travel hydraulic pump drives a crawler system motor

and gearbox. Each hydraulic pump and motor is controlled

with travel control handle movement and node controllers.

Travel control handles are inoperable when travel park brake

is applied. The gearbox for each crawler is driven with a

flexible shaft connected between the motor output and drive

gearbox input.

The left travel pump is dedicated to operate drum 3 through a

diverting valve if drum 3 is selected. The right travel pump is

dedicated to operate drum 4 through a diverting valve if drum

4 is selected under certain conditions when drum 5 is also

configured.

To ensure that crane travels in a straight line forward or

reverse direction, each travel drive system has shuttle valves

and pressure senders in each leg that monitor hydraulic

pressure. When traveling, Node-4 controller monitors

pressure information from pressure senders and adjusts

displacement of travel pumps to maintain equal pressure in

each travel drive system.

The source of hydraulic pressure for releasing the travel

brakes and enabling motor servo systems is from accessory/

MAX-ER pump at 500 psi (35 bar). Continuous changing of

closed-loop fluid occurs through leakage in pump, motor,

and loop flushing valves that removes 5 g/m (19 L/m) of fluid

to when system pressure is above 200 psi (14 bar).

The travel pumps output can be programmed for 25% to

100% of rated volume on Function Mode screen — see

Section 3.

When either travel control handle is moved from off, an input

signal is sent to Node-1 controller. Node-3 and 5 controllers

send a 24 volt signal to enable the rear and right side swing/

travel alarms. When both travel control handles are moved to

off, an input signal is sent to Node-1 controller. Node-3 and 5

controllers send a zero volt output signal to disable the rear

and right side swing/travel alarms.

Travel Brakes

Hydraulic pressure for releasing the travel brakes is output

pressure from accessory/MAX-ER pump at 400 to 500 psi

(28 to 35 bar). For travel brake operation the system

pressure must be above 200 psi (14 bar) for travel brakes to

fully release from each travel motor shaft. If system pressure

is below 200 psi (14 bar), travel brake could be partially

applied and damage the brake. If brake pressure or electrical

power is lost when operating, the travel brakes apply.

When travel brake switch is in on - park position, right and left

travel brakes are applied to hold crane in position. Travel

brake valve is open to allow hydraulic flow from the brake to

tank.

When travel brake switch is in off - park position, an input

signal is sent to Node-1 controller. Travel system circuit is

enabled, waiting for a travel control handle command. When

travel control handle is moved an input signal is sent to

Node-1 controller. Node-5 controller sends a 24 volt output to

enable travel brake release solenoid HS-5. Brake valve shifts

to block tank port and supplies low pressure hydraulic fluid

from accessory/MAX-ER pump to release crawler brakes. If

brake pressure or electrical power is lost when operating,

brakes apply.

Travel Forward and Reverse

When a travel control handle is moved in forward direction,

an input voltage of 2.6 or more volts is sent to Node-1

controller. Node-3 controller sends a variable 0 to 24 volt

output that is divided by a resistor and applied to selected

travel pump EDC. Node-5 controller sends a 24 volt output to

enable travel brake release solenoid HS-5 and release both

left and right crawler brakes, before travel pump(s) strokes.

The travel pump EDC tilts pump swashplate in the forward

direction. Hydraulic fluid flow is from selected pump ports

through swivel to motor ports. Node-3 controller input voltage

to travel pump EDC is relative to control handle movement.

When a travel control handle is moved in reverse direction,

an input voltage of 2.4 volts or less is sent to Node-1

controller. Node-3 controller sends a variable 0 to 24 volt

output that is divided by a resistor and applied to selected

travel pump EDC. Node-5 controller sends a 24 volt output to

enable travel brake solenoid HS-5 and release both left and

right crawler brakes, before travel pump(s) strokes.

The travel pump EDC tilts the pump swashplate in the

reverse direction. Hydraulic fluid flow is from selected pump

ports through swivel to motor ports. Node-3 controller input

voltage to selected travel pump EDC is relative to selected

control handle movement.

FIGURE 1-18

HS-14

HS-5

HS-6

HS-28

Brake

Pressure

Sender

Diverting

Valve

Accessory Pump

(Low-Pressure)

Pressure

Sender

Motor

(PCP)

Pump

(EDC)

16-1010

Diverting

Valve

Pressure

Sender

Pressure

Sender

Pump

(EDC)

2-Speed

Loading...

Loading...