Manitowoc Published 05-09-17, Control # 014-28 5-3

16000 SERVICE/MAINTENANCE MANUAL HOISTS

Weekly Maintenance

1. Check minimum bail limit switch for proper operation.

a. LED (light emitting diode, Past Production only)

should be on for normal operation. For both Past

and Current Production, limit switch should be

depressed to dimension given in Figure 5-3

for

normal operation.

b. Pay out wire rope from drum. Drum should stop with

approximately 3 to 4 wraps of wire rope remaining

on first layer (LED off on Past Production only).

Adjust limit switch if necessary.

2. Check that cap screws holding rollers on lever shaft are

tight.

3. Check tension of return springs. If necessary, adjust

eyebolts so springs hold rollers snug against bare drum.

Adjustment

1. Pay out wire rope until rollers are against bare drum with

3 to 4 wraps of wire rope remaining on first layer.

2. Ensure rollers (2) contact drum (4).

3. Turn adjusting screw (6) until limit switch is depressed to

the 43,4 mm (1.7 in) dimension given in Figure 5-3

.

4. Spool several wraps of wire rope onto drum. Then pay

out wire rope. Drum must stop with 3 to 4 wraps of wire

rope remaining first layer.

Repeat adjustment steps if necessary.

5. Tighten jam nut against mounting plate to lock

adjustment.

6. Check that return springs have sufficient tension to hold

rollers snugly against bare drum. Adjust eyebolts if

necessary.

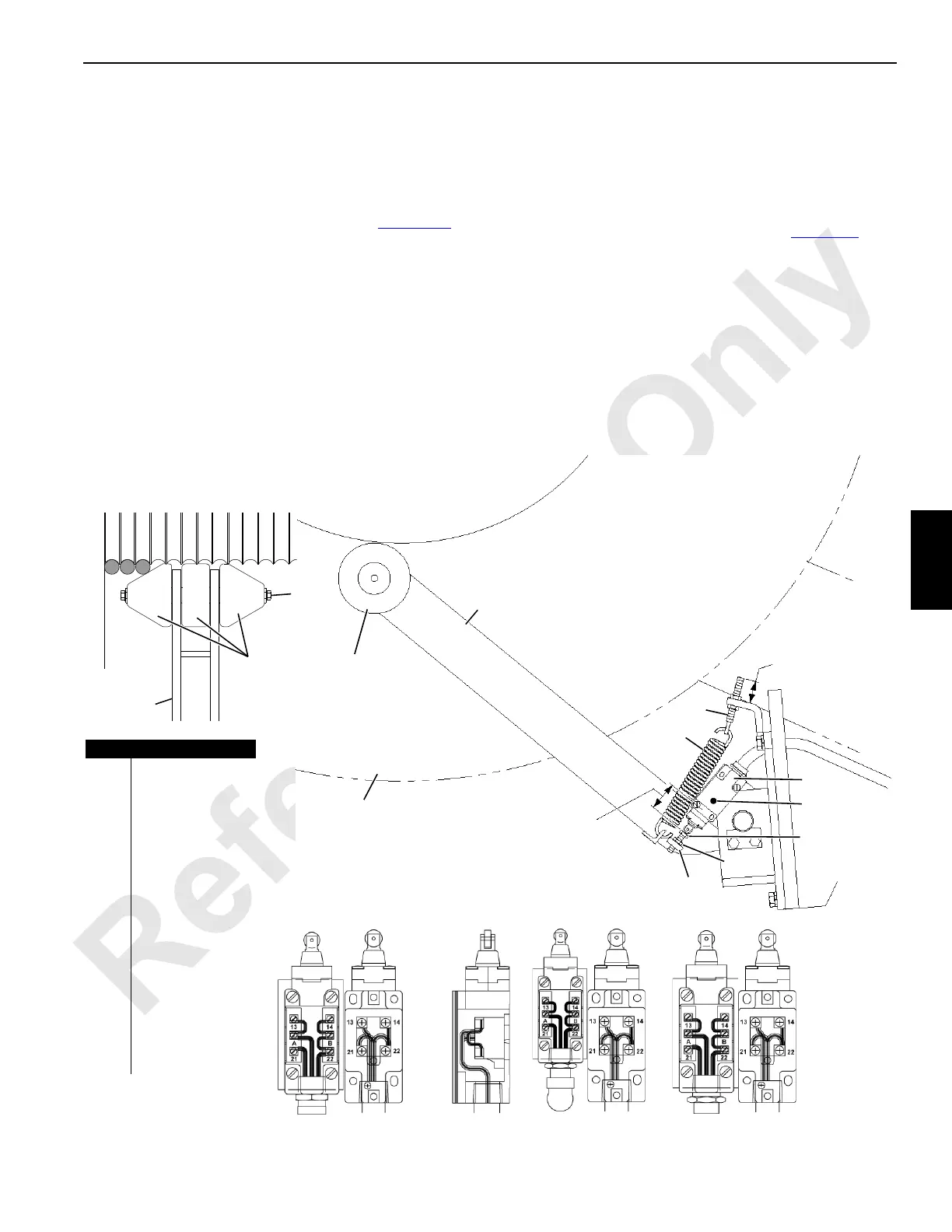

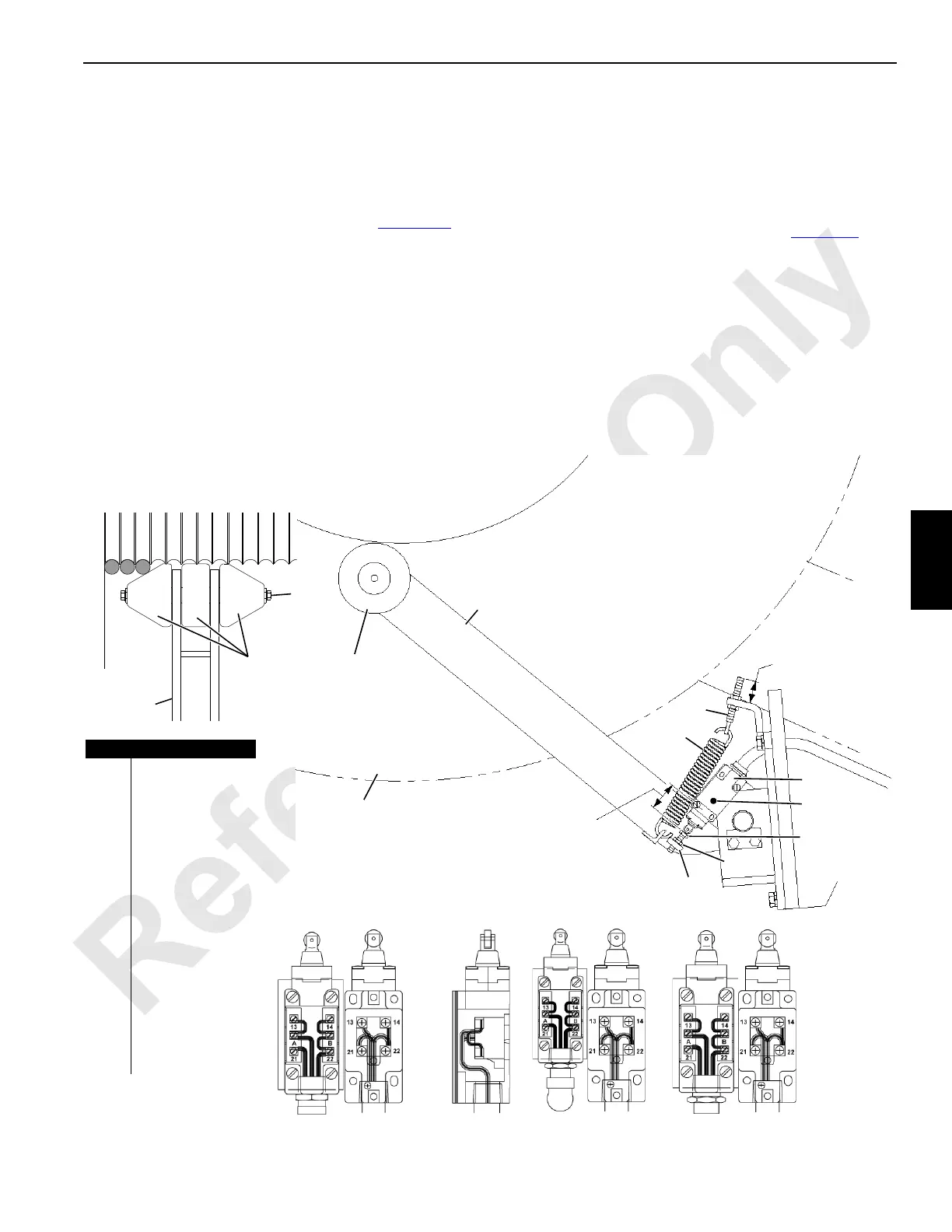

FIGURE 5-3

195918

3 to 4 Wraps of Wire Rope

Remaining on Drum

View from Left Side

Drum 1 — Main Hoist — Shown

Drum 2 — Auxiliary Hoist — Similar

Item Description

1Lever

2Rollers

3 Cap Screw

4Drum

5Jam Nut

6 Adjusting Screw

7 Limit Switch

8LED (Past

Production only)

9 Mounting Plate

10 Return Spring

11 Eyebolt

12 Drum 2 Max. Bail

Limit Switch Wiring

13 Drum 1 Min. Bail

Limit Switch Wiring

14 Drum 3 Min. Bail

Limit Switch Wiring

1

2

3

11

10

2

1

7

4

6

A16425

1.22 in (30,9 mm)

When New

1.71 in

(43,4 mm)

8

9

5

Past

Current

Past

Current

Past

Current

12

13

14

Loading...

Loading...