Manitowoc Published 05-09-17, Control # 014-28 7-3

16000 SERVICE/MAINTENANCE MANUAL POWER TRAIN

Table 7-3 Open Circuit Cell Voltage

NOTE: Detailed test information is provided by the meter

manufacturer.

High Resistance Test

When cranking, a voltage drop of more than 0.2 volts

between the starting motor cable and ground can cause hard

starting regardless of a battery’s condition. The voltage drop

can be caused by a poor contact between the cable terminal

and ground or between the clamp terminal and the battery

post. Poor start-switch contacts and frayed, broken, or

corroded cables can also be the cause.

Quarterly

1. Thoroughly clean the batteries and the holder with

baking soda.

2. If provided, make sure the drain holes are open in the

holder. If water collects in the holder, drill drain holes.

3. Clean the posts and terminals. The posts can be tightly

coated with grease to prevent corrosion.

4. Make sure the hold-downs are in good condition;

replace faulty parts.

5. Replace frayed, broken, or corroded cables.

6. Replace the batteries if their containers are cracked or

worn to the point they leak.

7. Ensure a good tight contact between the clamp

terminals and battery posts.

8. Make sure the hold-downs are tight enough to prevent

battery movement but not so tight to cause distortion.

Charging

The battery should be at room temperature when recharging.

Before a battery is recharged, it must be thoroughly cleaned.

Take care not to allow dirt to enter the cells.

A battery should be recharged in the way it was discharged.

If it was discharged over a long period of time, it should be

recharged slowly at 6 to 10 amperes for up to 10 hours. A

rule-of-thumb value for a slow rate is a current equal to about

one-half the number of plates per cell in the battery. A battery

with 13 plates per cell, should, therefore be charged at 7

amperes.

If a battery was discharged rapidly (cranking until dead), it

can be recharged on a fast charger with an output of up to 40

amperes for a maximum of 2 hours. If the electrolyte

temperature reaches 52°C (126°F) or if it gases violently, the

charging current must be reduced or halted to avoid battery

damage.

For optimum charging results, adhere to the charger

manufacturer’s instructions.

Storage

When the crane is left idle for prolonged periods, it should be

run periodically to charge the batteries.

When storing a battery, make sure it is at least 75% charged

to prevent the possibility of freezing.

Follow your battery dealer’s recommendations.

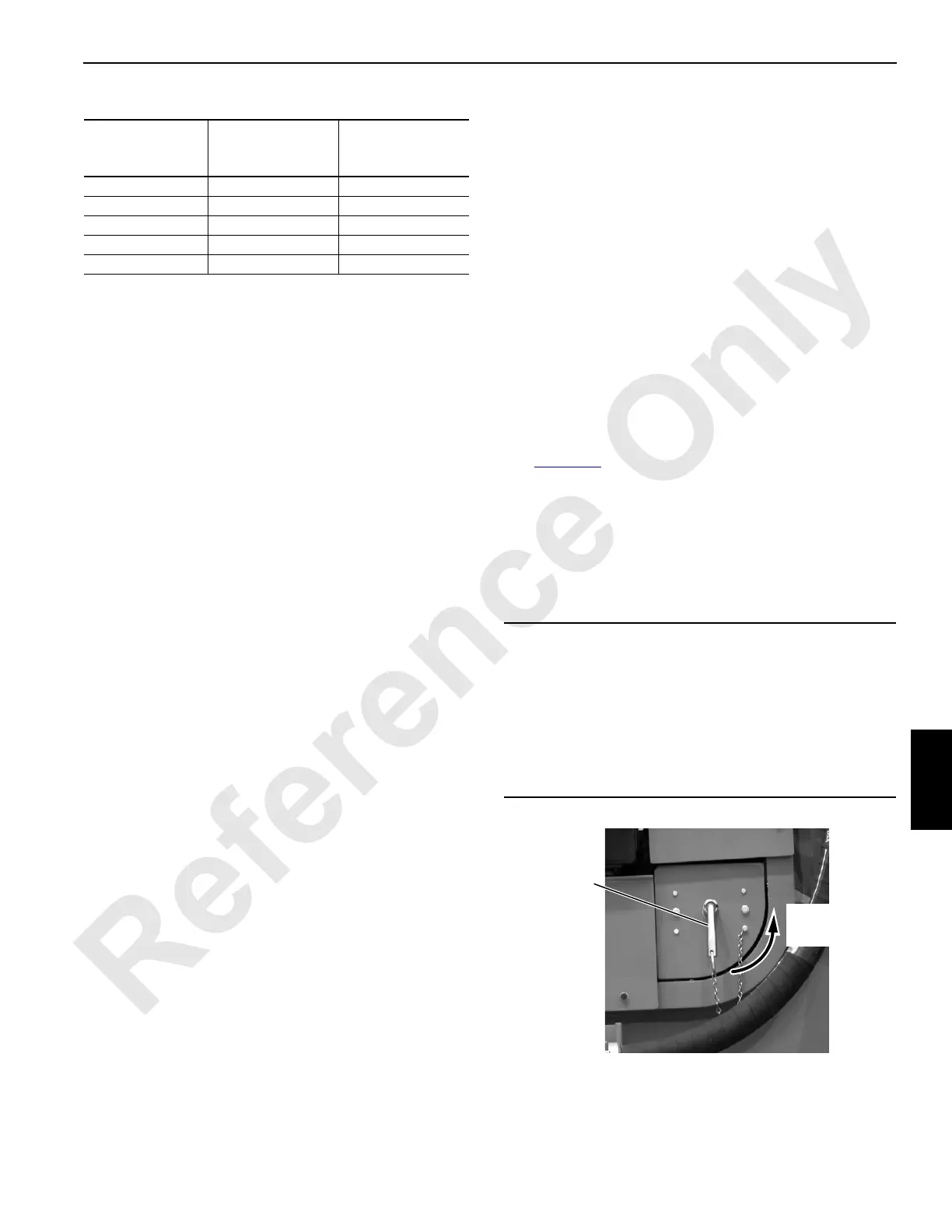

Battery Disconnect Switch

See Figure 7-2 in the following procedure.

A battery disconnect switch is provided on the right side of

upperworks near the engine node. Use the switch to

disconnect the batteries when servicing the electrical control

system.

See Section 3 of Crane Operator Manual for operation of

the battery disconnect switch.

% Charge Specific Gravity

Approximate

Open Circuit

Cell Voltage

100 1.260 2.10

75 1.230 2.07

50 1.200 2.04

25 1.170 2.01

Discharged 1.110 1.95

CAUTION

Engine Damage!

To avoid possible engine fault codes and undesirable

operation, make sure engine ignition switch has been off

five minutes before disconnecting batteries.

Do not rely on this switch to protect crane’s electronic

systems when welding. Disconnect battery cables at

batteries before welding.

FIGURE 7-2

Shown In

Connected

Position

IMG7563

Right Side of Rotating Bed

To

Disconnect

Loading...

Loading...