Manitowoc Published 05-09-17, Control # 014-28 1-39

16000 SERVICE/MAINTENANCE MANUAL INTRODUCTION

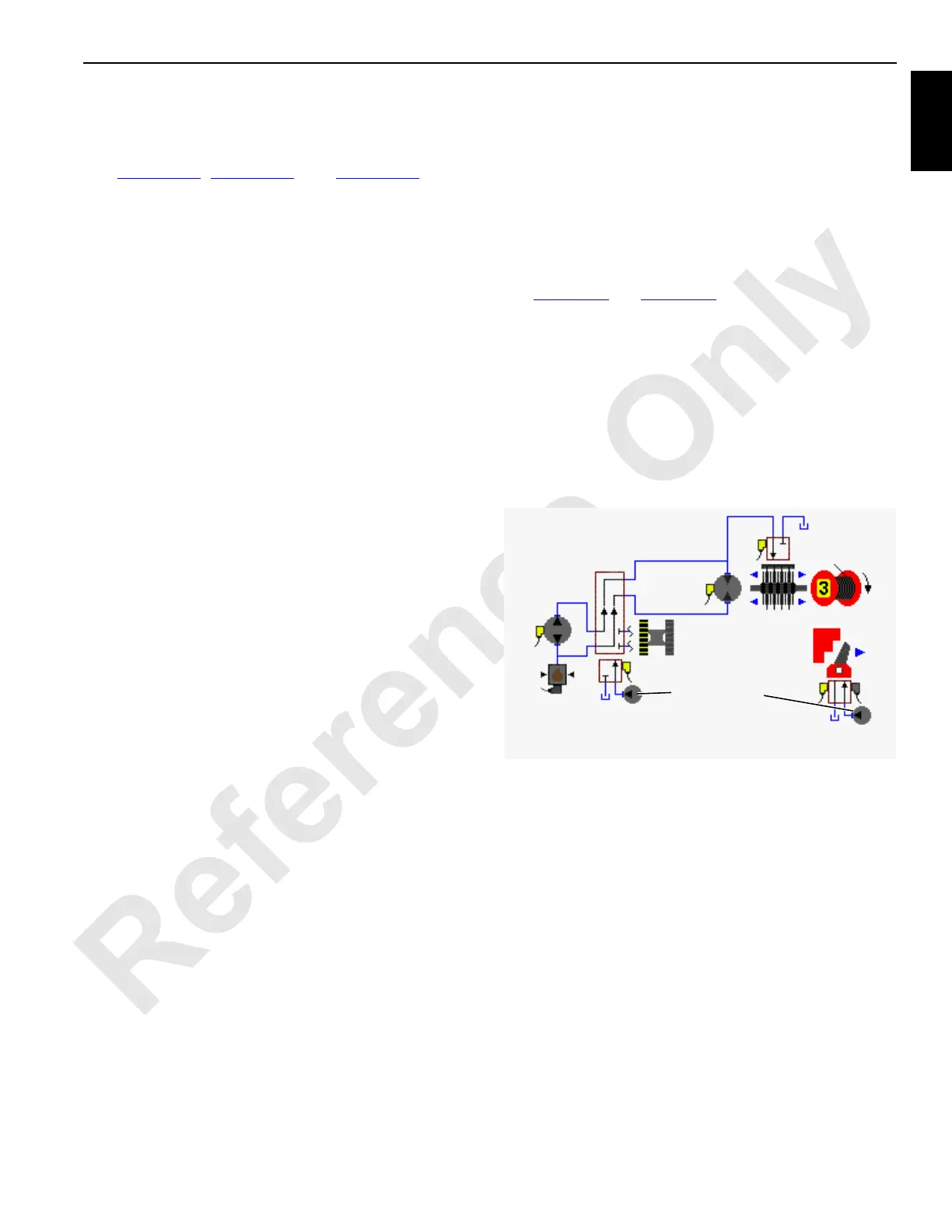

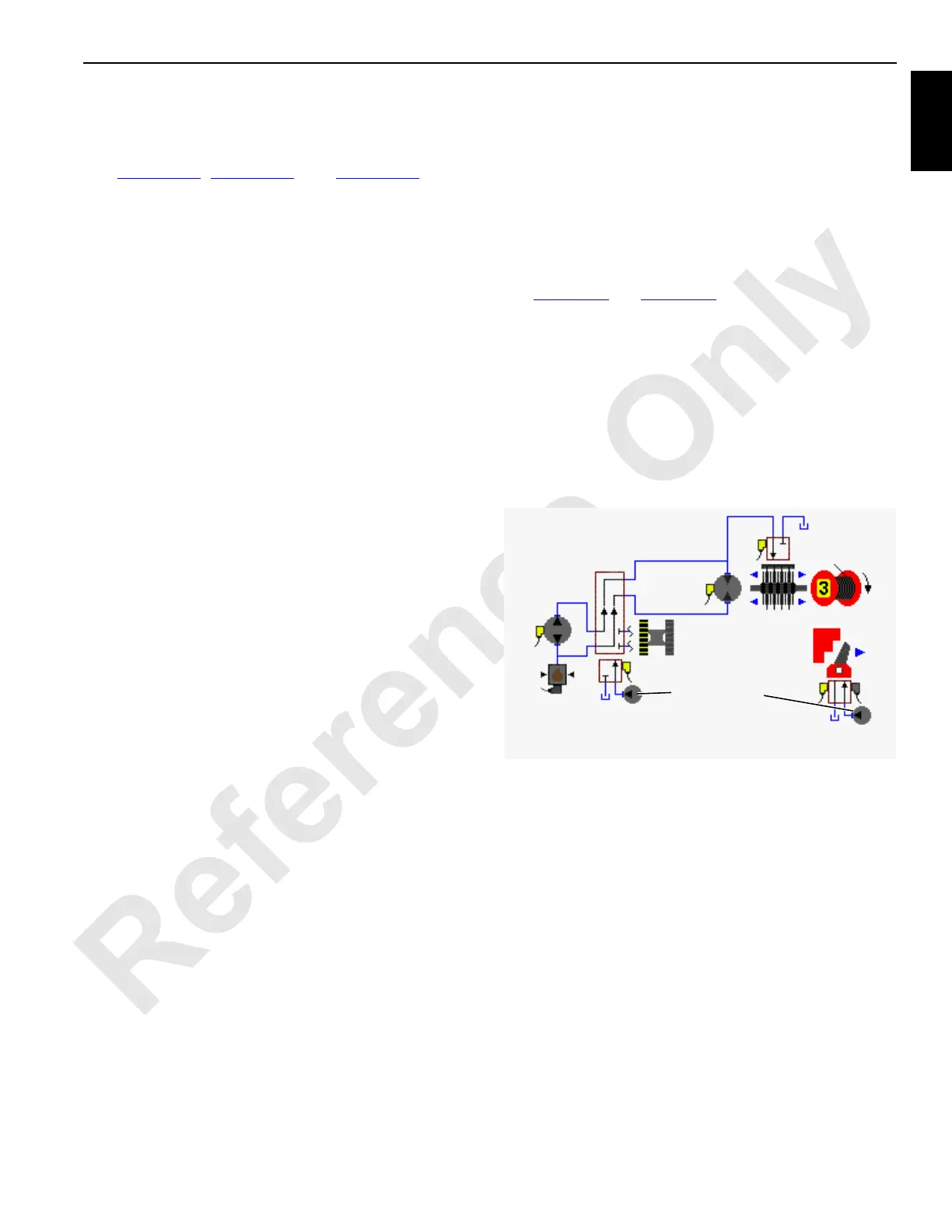

LOAD/LUFFING DRUM 3

System Components

See Figure 1-29, Figure 1-30, and Figure 1-31 for the

following procedure.

The Load/luffing drum 3 is located in the boom butt. The

drum can be configured for either luffing jib operation or as

an auxiliary drum. If drum 3 is rigged for luffing jib operation it

can not be used as a load drum.

One hydraulic pump drives one motor gearbox on left side

end of drum 3. The left travel pump is dedicated to operate

drum 3 though a diverging valve. The left track and drum 3

can not be operated at the same time. Hydraulic connections

between the pump and motor form a closed-loop system that

is controlled with control handle movement and node

controllers. The far load drum control handle on the right side

console operates drum 3 when configured a load drum.

When configured as a luffing jib the control handle on left

side console operates drum 3. The control handle is

inoperable when drum 3 park brake is applied.

Hydraulic charge pressure from system charge pump

supplies hydraulic make-up fluid to low-pressure side of

motor. A pressure sender in high-pressure side of pump leg

provides system pressure information to Node-1 controller.

Low-side pressure supplies hydraulic pilot pressure to

operate motor servos. A fixed orifice between pump ports A

and B allows for smoother drum operation.

When load drum 3 motors rotate, a speed sensor at motor

rotor monitors and sends an input voltage to Node-1

controller. Node-2 controller sends an output voltage to

rotation indicator in control handle. As drum rotates faster,

the rotation indicator on top of control handle pulsates with a

varying frequency that indicates drum rotational speed. The

handle command in percent from neutral is shown on

Diagnostic Screen.

Continuous changing of closed-loop fluid occurs with

leakage in pump, motor, and external sequence/flow valve.

Sequence/flow valve opens at 200 psi (14 bar) and removes

4 gallons per minute (15 l/m) of hot fluid from system by

discharging exhausted fluid into motor case where the fluid

returns to tank.

Load Drum 3 Brake and Pawl

Hydraulic pressure to operate drum 3 brake is from low-

pressure side of system. Hydraulic pressure to operate drum

pawl is from low pressure accessory system.

When drum 3 brake switch is in on - park position, drum

brake release solenoid HS-25 is disabled so brake is applied

to drum shaft. Drum 3 pawl in solenoid HS-26 is enabled to

keep pawl applied to drum flange. Drum pump does not

stroke in response to control handle movement.

When drum 3 brake switch is placed in off - park position,

brake release solenoid HS-25 remains applied. Brakes

remain applied until Node-6 controller sends a 24 volt output

to release the brake. Node-6 controller sends a zero volt

output signal to drum pawl in solenoid HS-26 and a 24 volt

output to enable pawl out solenoid HS-27 to release pawl.

The drum circuit is active, waiting for a control handle

command.

Raising

See Figure 1-29 and Figure 1-31 for the following procedure.

When drum 3 control handle is moved back for raising, an

input voltage of 2.6 volts or more is sent to Node-1 controller.

Node-4 controller sends a 24 volt output to enable left travel

to drum 3 diverting solenoid HS-28. Node-3 controller sends

a variable zero to 24 volt output that is divided by a resistor

and applied to pump 2 EDC in the raising direction. Node-6

controller sends a variable zero to 24 volt output that is

divided by a resistor and applied to motor PCP. Node-1

controller checks that drum block-up limit switches are

closed and no system faults are present.

Pump EDC tilts swashplate in raising direction to satisfy

pressure memory. Node-1 controller compares drum holding

pressure to value in pressure memory. When system

pressure is high enough, Node-6 controller sends a 24 volt

output to enable drum 3 brake release solenoid HS-25. Drum

brake solenoid shifts to block drain port and opens port to

low-pressure side of drum system to release brake from

drum shaft.

The pump EDC tilts swashplate in the raising direction as

hydraulic fluid flow is from pump port to motor port. Return

fluid is from motor outlet port to pump inlet port.

Node-3 controller output voltage to pump EDC and Node-6

controller output voltage to motor PCP is relative to control

handle movement. As control handle is moved back, an

output voltage increases the pump swashplate angle.

When system pressure exceeds the PCOR (Pressure

Compensating Over-Ride) valve setting of 4,930 psi (340

bar), the valve shifts to direct flow from shuttle valve into

FIGURE 1-29

HS-25

HS-27

HS-28

Brake

Diverting

Valve

Motor

(PCP)

Pump

(EDC)

Pressure

Sender

Pawl

HS-26

16-1021

Accessory Pump

(Low-Pressure)

Loading...

Loading...