Manitowoc Published 05-09-17, Control # 014-28 7-9

16000 SERVICE/MAINTENANCE MANUAL POWER TRAIN

ENGINE CLUTCH ADJUSTMENT

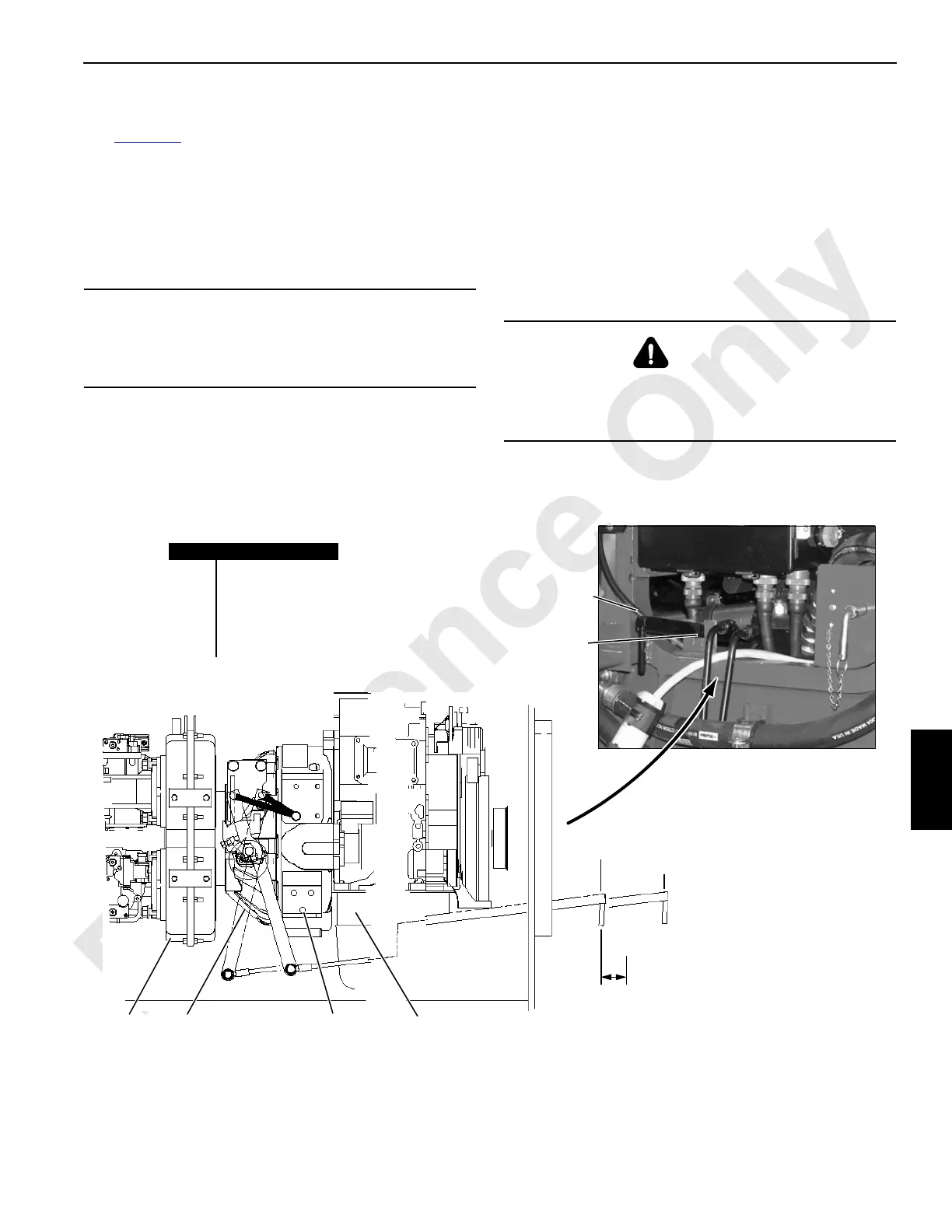

See Figure 7-5 for the following procedure.

A disc-type manually operated clutch is mounted between

the engine and the pump drive on this crane. The clutch

allows the pump drive to be disconnected from the engine,

thereby reducing engine load and making start-up easier in

cold weather. The clutch can be engaged or disengaged

while the engine is running or off.

Operation

1. Grease clutch monthly. See Section 9.

2. At least once each month, disengage and engage the

clutch several times with engine running. This practice

will clean the disc surfaces and prevent the discs from

seizing.

3. When disengaging clutch, check free travel. Readjust

clutch when free travel decreases to less than 1-3/8 in

(35 mm).

Adjustment

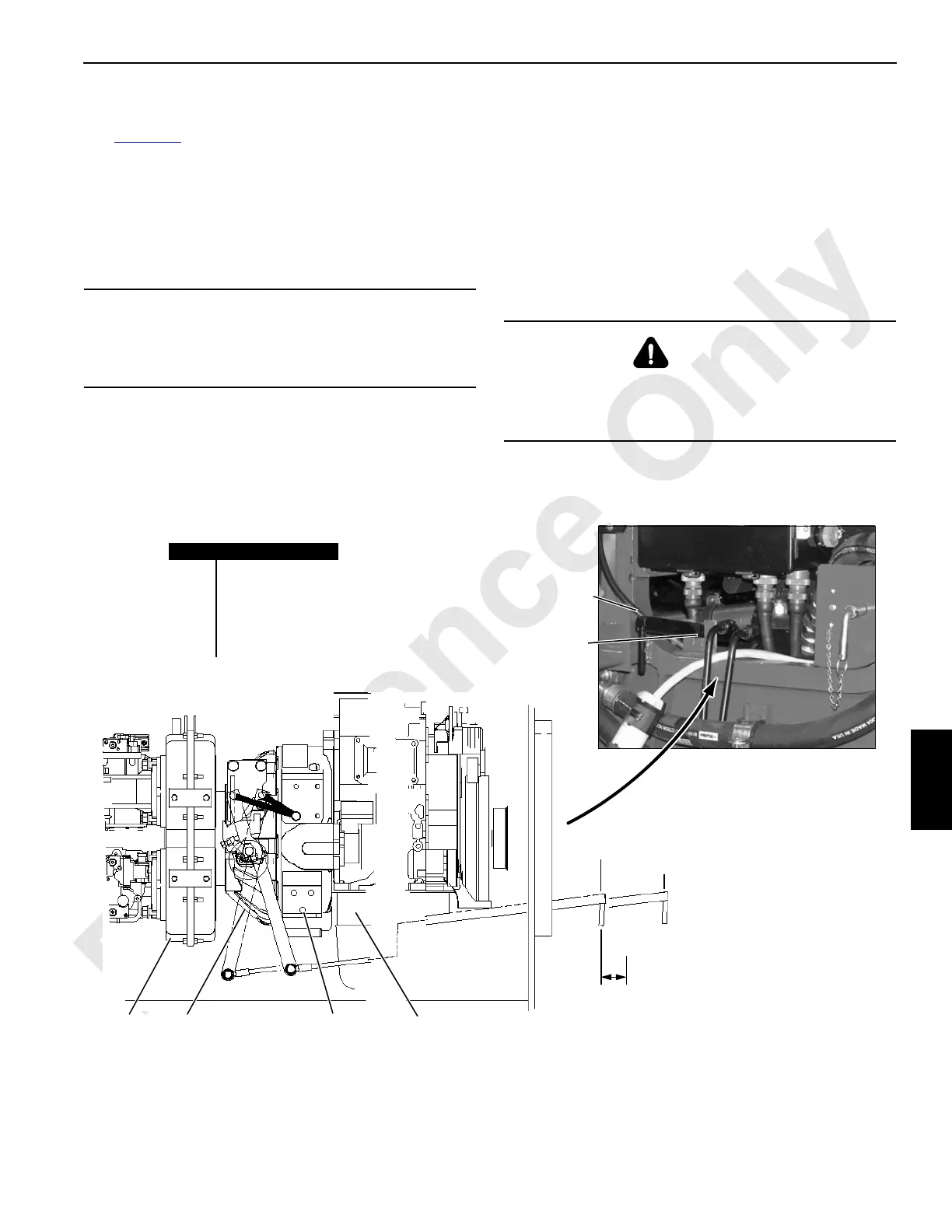

The clutch is adjusted internally through the cover plate on

top of the clutch housing. See the clutch manufacturer’s

manual for adjustment instructions.

CAUTION!

Parts Damage!

Do not run engine longer than 20 minutes with clutch

disengaged. Clutch release bearing can be damaged.

DANGER!

Moving Machinery Hazard!

Parts inside clutch rotate when engine is running. Stop

engine before adjusting clutch.

FIGURE 7-5

View From Rear of Crane

Item Description

1 Handle

2Latch

3 Engine

4Clutch

5 Cover Plate

6 Pump Drive

1 – DISENGAGED

1 – ENGAGED

Readjust Clutch When Free Play

is Less Than 1-3/8 in (35 mm)

1

2

3456

P2290

Loading...

Loading...