Manitowoc Published 05-09-17, Control # 014-28 1-17

16000 SERVICE/MAINTENANCE MANUAL INTRODUCTION

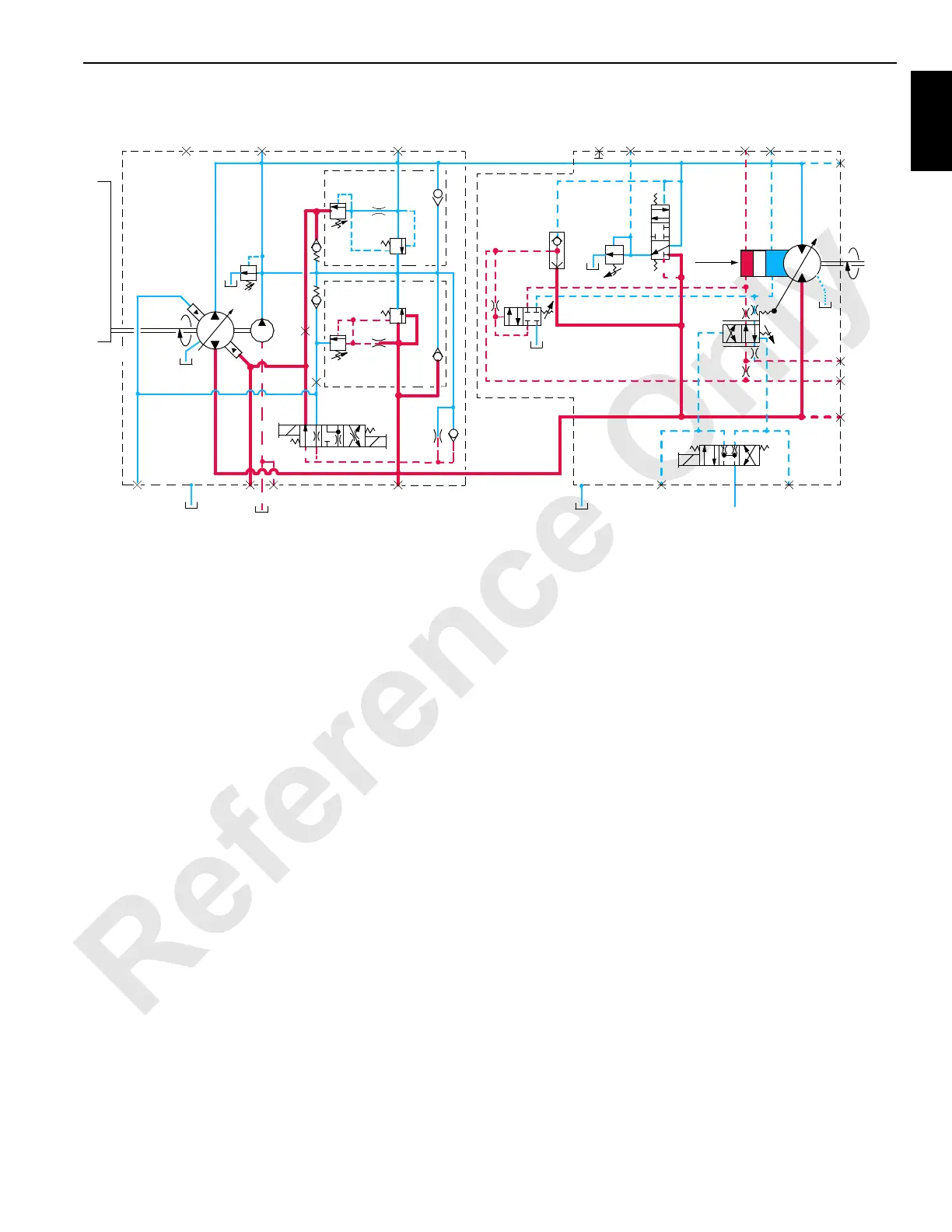

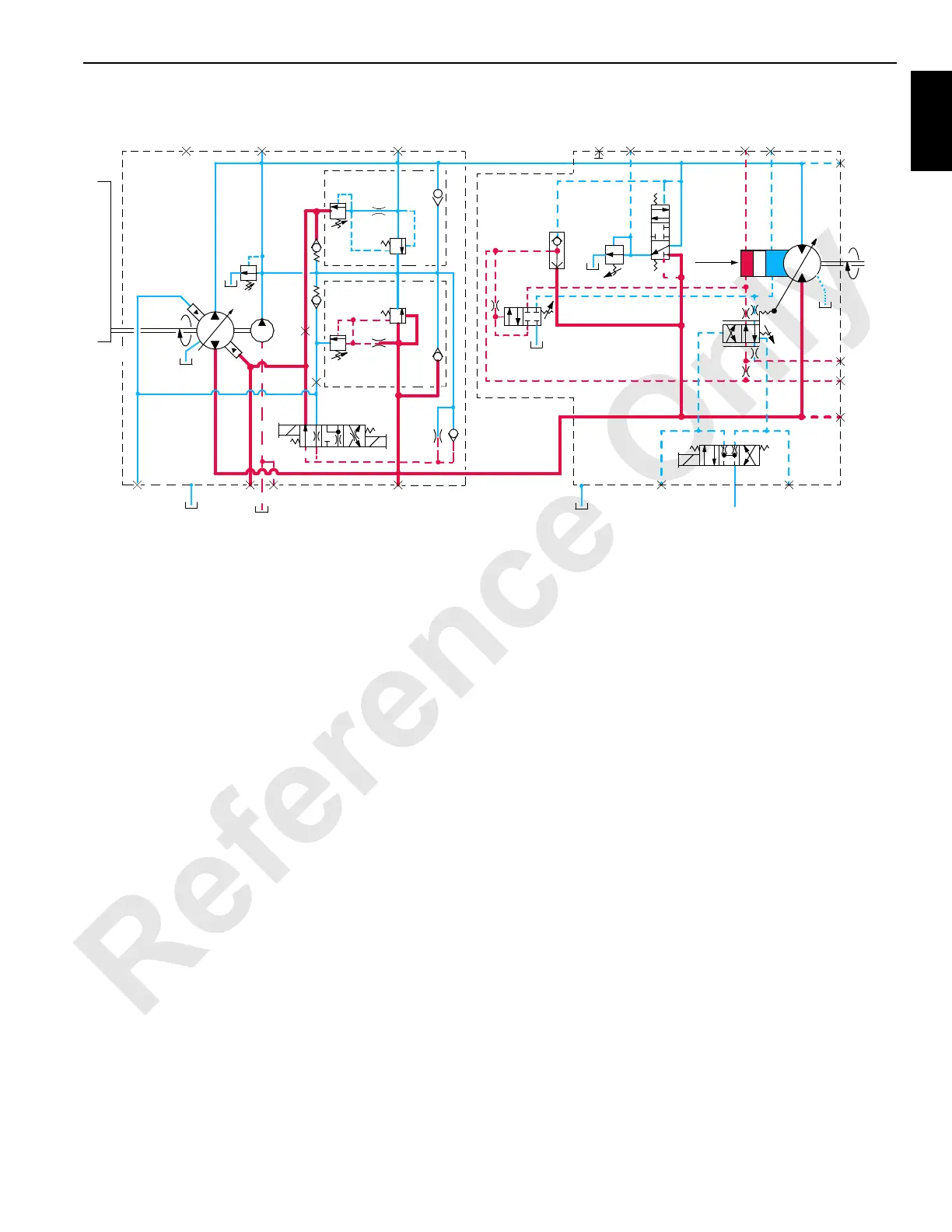

The load drums and boom/mast hoist motors also have a

PCOR (Pressure Compensating Over-Ride) valve (16) that

is enabled when system pressure of 4,930 (340 bar) is

reached. When system pressure exceeds the PCOR setting,

the valve shifts to direct flow from shuttle valve into maximum

displacement side of servo cylinder. The PCOR valve over-

rides the command from servo PC valve, increasing motor

displacement and output torque and reducing output speed.

When PCOR valve closes, control of the motor returns to

servo PC valve.

The travel motor servo is opposite of other system motors.

The travel variable displacement motors begin operation at

minimum displacement (low torque, high speed). The motor

shifts to maximum displacement (high torque, low speed)

when starting torque is required and back to minimum

displacement when in motion if load is below a preset

pressure of 3,915 psi (270 bar). Depending on motor system,

servo uses low pressure accessory system pressure to

perform the shifting operation. Servo control fluid shifts

shuttle valve and servo control valve before entering servo

cylinder.

Continuous changing of closed-loop fluid occurs through

leakage in pumps, motors, and loop flushing valves. Motor

case fluid drainage lubricates the motor and provides a re-

circulation of hydraulic fluid to control heat in closed-loop

system. Motors also have an internal or external loop

flushing (purge) system that consists of control valve (17)

and relief valve (18). If system pressure is above 200 psi (14

bar), loop flushing removes 4 g/m (15 L/m) of hot fluid from

system for added cooling and purification. If system pressure

is under 200 psi (14 bar) loop flush is disabled.

Accessory/MAX-ER Pump

The accessory/MAX-ER pump is the source of pressure for

accessory system components. The programmable

controller controls the pump output pressure when an

accessory valve is enabled.

Accessory/MAX-ER pump supplies hydraulic fluid to operate

the jacking cylinders, pin cylinders, mast raising cylinders,

rigging winch, and cab tilt cylinder. Accessory pump

pressure is reduced from 3,000 to 500 psi, 400 psi at standby

(207 to 34.5 bar, 27.6 bar at standby) by the reducing valve

for travel brake, travel two-speed, swing brake, and swing

lock (past production).

NOTE: An external pump on the engine operates the

engine cooling fan. On 16001142 and newer the

accessory pump will also control the cooling fan.

Tier 4 equipped machines will have a variable

speed cooling fan.

Engine Controls

See engine manufacturer’s manual for instructions.

The engine is started and stopped with engine key switch.

Engine clutch lever for pump drive must be manually

engaged for normal operation.

T1

T2

T3

3

8

1

2

14

5

16

7

9

11

12

10

15

18

17

13

6

4

FIGURE 1-10

Pump

Motor

Pump Drive

Input

350 psi

(24 bar)

A

D

C

Max.

Disp.

L2

M6

M4 M3

M1

M9

M5

M2

Output

G

M8E

B

M7

A

D

F

A

B

16-1003

Loading...

Loading...