Manitowoc Published 05-09-17, Control # 014-28 1-49

16000 SERVICE/MAINTENANCE MANUAL INTRODUCTION

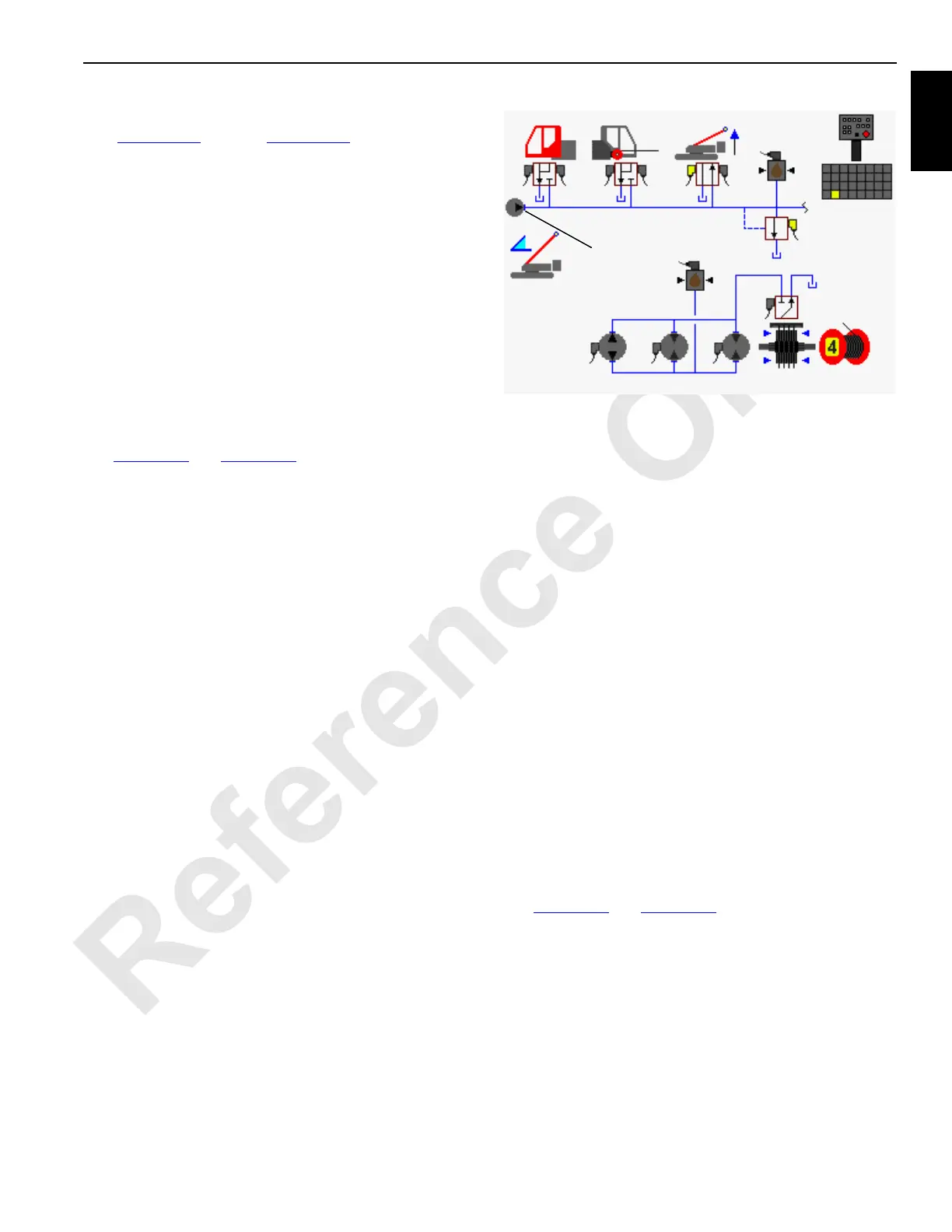

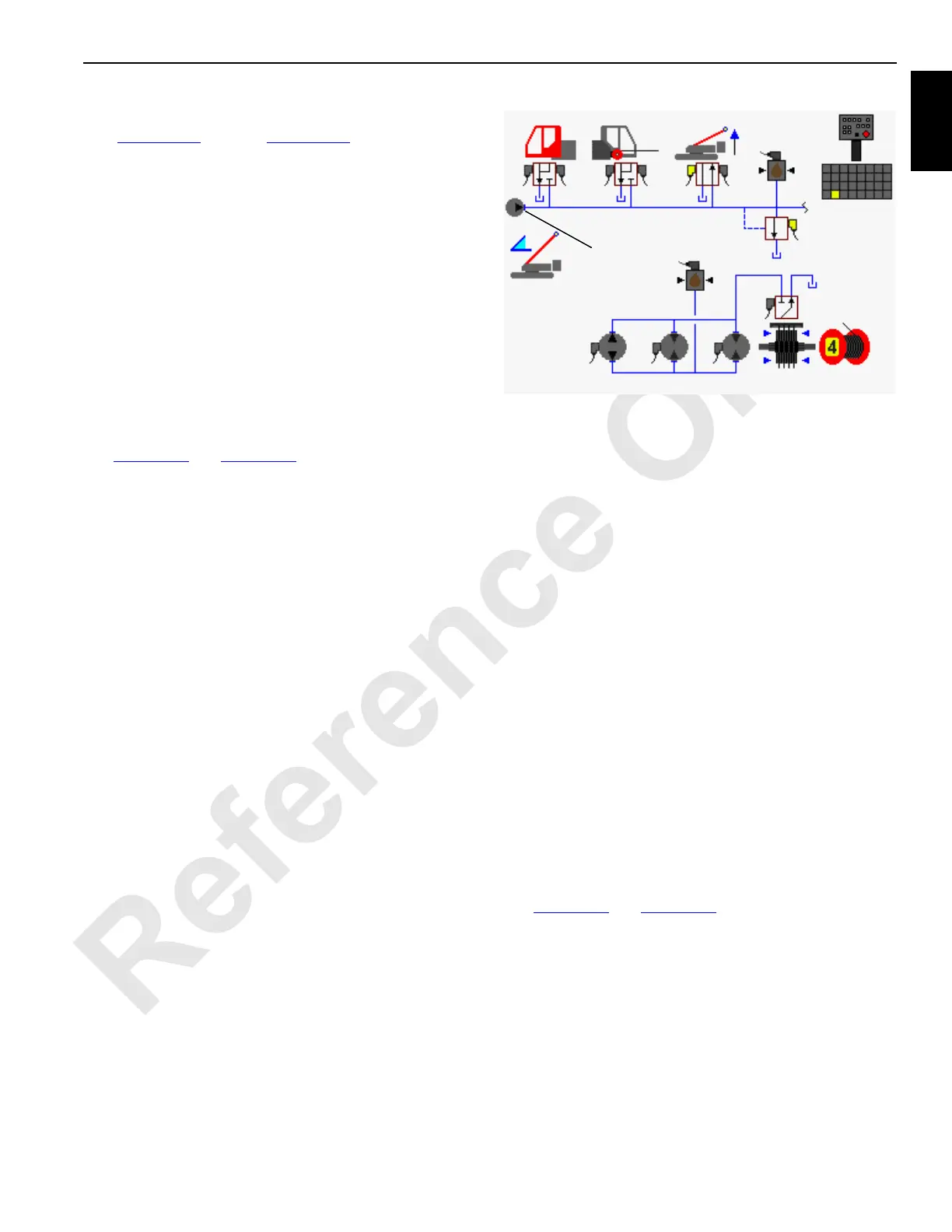

Live Mast

See Figure 1-46 through Figure 1-49 for the following

procedure.

The live mast is the rectangular shaped structure that

supports the boom. The mast is also used for crane

assembly and disassembly.

The mast-raising sequence is controlled automatically by the

computer program and the boom/mast hoist control handle.

Mast raising and lowering rate is controlled by engine speed,

as it regulates pay out and haul in of the cable reeving

between boom/mast hoist sheaves and mast sheaves.

Mast system faults appear on the information screen when

the mast is inoperable in either direction or mast is at

maximum lower position. Stop operating when a fault

appears.

Mast Raising/Lowering with Mast Switch

See Figure 1-46 and Figure 1-49 for the following procedure.

The mast switch on hand-held wireless remote should only

be used for raising/lowering mast cylinders without wire rope

rigging. Power is available to hand-held wireless remote

control when engine is running, and power button is pressed.

When not enabled, mast raising cylinders are motor

spooled where both cylinder ports and tank port of valve

spool section are connected in center position. This type of

spool prevents premature opening of equalizing valves.

Load equalizing valves ensures mast-raising cylinders

operate in unison, protecting mast from structural damage

caused by twisting. Load equalizing valves also provides

support resistance against mast to ensure control of the unit

while rotating it at assembly. When an accessory valve spool

shifts, supply flow to the other accessory valves is limited.

The accessory system pressure sender monitors accessory

system pressure.

When mast cylinders switch is placed in the raise position

and held, an input voltage is sent to Node-1 controller. Node-

4 controller sends a 24 volt output to enable mast cylinders

raise solenoid HS-50 and shifts valve to the raise position.

Node-3 controller sends a variable zero to 24 volt output to

enable accessory system proportional relief solenoid HS-68.

See automatic raising/lowering procedure below for

complete cylinder operation.

When mast cylinders switch is released, solenoid HS-50

returns to center position. Node-3 controller sends a zero

volt output to disable accessory system proportional relief

solenoid HS-68.

When mast cylinders switch is placed in the lower position

and held, an input voltage is sent to Node-1 controller. Node-

4 controller sends a 24 volt output to enable mast cylinders

lower solenoid HS-51 and shifts valve to the lower position.

Node-3 controller sends a variable zero to 24 volt output to

enable accessory system proportional relief solenoid HS-68.

See automatic raising/lowering procedure below for

complete cylinder operation.

When mast cylinder switch is released, solenoid HS-50

returns to center position. Node-3 controller sends a zero

volt output to disable accessory system proportional relief

solenoid HS-68.

Mast Raising from Transport Position

See Figure 1-47 and Figure 1-49 for the following procedure.

Use RCL Screen to select the Liftcrane Mast Handling

Capacity Chart. The mast controls will not operate and the

mast operating limits remain off until the Liftcrane Mast

Handling Capacities Chart is selected.

Use mast switch on hand-held wireless remote to raise mast

assist arms until cylinders stall and stop.

When boom/mast hoist control handle is moved forward for

lowering, an input voltage of 2.4 volts or less is sent to

Node-1 controller. Node-3 controller sends a variable 0 to 24

FIGURE 1-46

Pressure

Sender

Accessory

Pump

Mast

Raising

Cylinders

Hand-Held

Wireless

Remote

HS-68

HS-51

HS-50

16-1036

500 to 3,000 psi

(35 to 204 bar)

Loading...

Loading...