INTRODUCTION 16000 SERVICE/MAINTENANCE MANUAL

1-64

Published 05-09-17, Control # 014-28

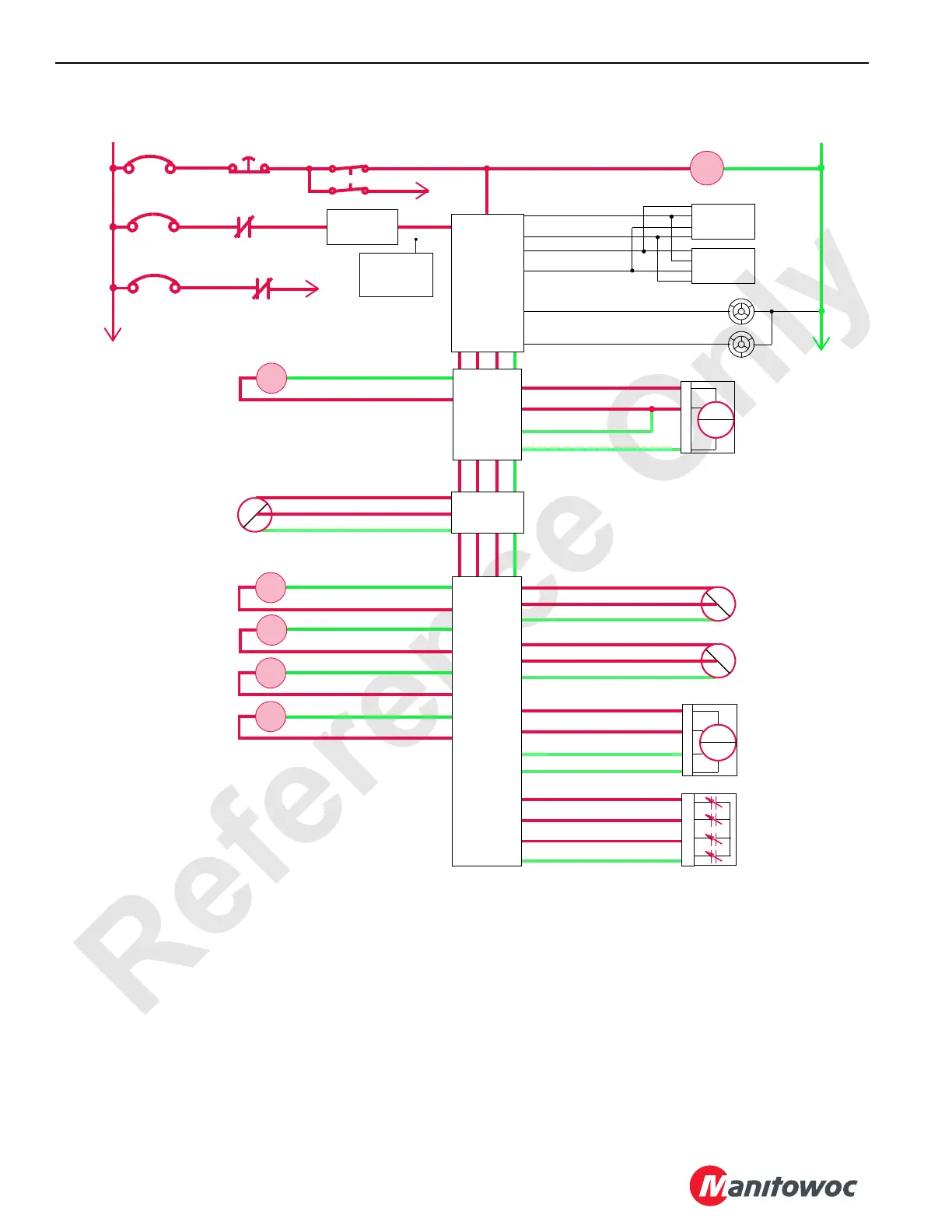

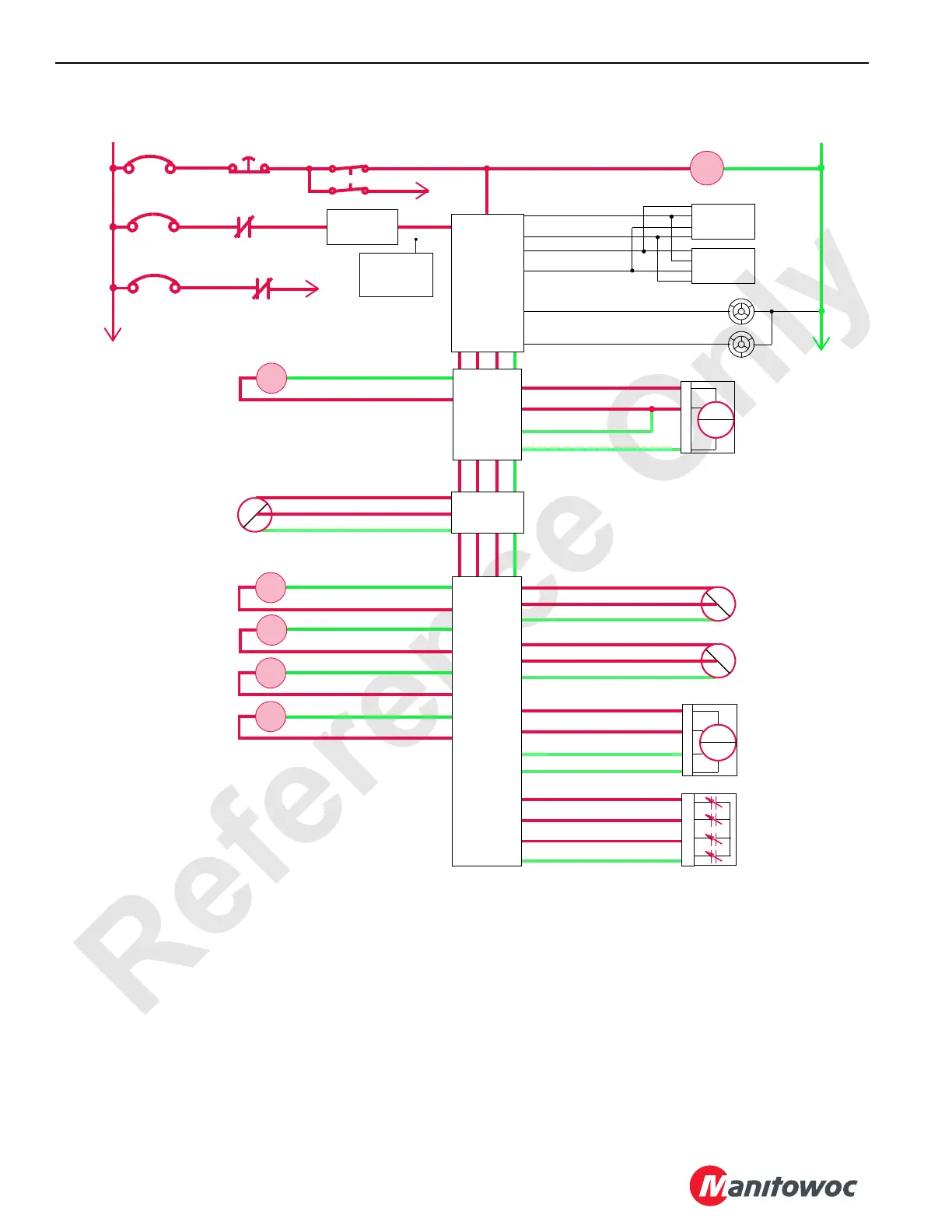

Counterweight Lift Cylinder Retract

When counterweight lift cylinder switch is moved and held in

retract position, an input signal from wireless transmitter is

sent to a receiver on the crane. The receiver sends the input

signal to Node-1 controller. Node-7 sends a 24 volt output to

enable the counterweight lift cylinder solenoids (HS-73 and

74) and shifts the valve to retract position.

Node-3 controller also sends a variable zero to 24 voltage to

enable proportional relief solenoid HS-68 to provide

approximately 4,500 psi (310 bar) pressure to counterweight

lift cylinder system.

Hydraulic pressure from accessory pump flows through

pressure control pilot valve, three bank manifold valve, and

enters free-flow check valve section of counterbalance

Counterweight Lift

Cylinder Extend

Pressure Sensor

MAX-ER Base Level

Sensor

+

–

PWR

CAB

System Fault Alarm

RCL Cab Fault Alarm

P11-07

P11-19

Display 1

Display 2

P11-01

P12-31

P12-32

P11-21

Start

WCP

CAN Power

Run 3

P12-24

Cab Power

Engine Stop

10 Amp

50 Amp

24 Volts

50 Amp

6C5A

6C5

CB7

6A

6C7

6C14

CB5

CB8

8C

8

NODE 0

NODE 1

(Master)

73-U

Counterweight Lift

Cylinder Retract

Pressure Sensor

73-E

73-a

Hyd

psi

73-V

73-A

73-c

Hyd

psi

24 Volts

AI

Gnd

24 Volts

AI

Gnd

76-a

76-E

76-S 24 Volts

AI

Gnd

76-b

AI

73-X

73-N

73-d

24 Volts

AI

Gnd

73-N

AI

Counterweight Lift

Cylinder Position

Sensor

Mag

LD

2

3

1

A

B

C

D

2

3

1

A

B

C

D

HS

72

HS

70

73-G

73-D

73-C

73-B

73-D

73-B

73-C

Counterweight Lift

Cylinder Extend

73-G

HS

73

HS

71

Counterweight Lift

Cylinder Extend

Counterweight Lift

Cylinder Retract

Counterweight Lift

Cylinder Retract

NODE 7

HS

68

Gnd 34-C

DO 34-D

Accessory System

Proportional Valve

46-g

Accessory System

Pressure Sensor

46-j

46-h

Hyd

psi

24 Volts

AI

Gnd

2

3

1

FIGURE 1-57

M16-12

36-m

36-J

36-k

24 Volts

AI

Gnd

36-Z

Gnd

Mast Strap

Load Pin

Load

Pin

A

B

D

NODE 3

Hand-Held

Wireless

Remote

Counterweight Lift Cylinder

DO

DO

DO

DO

Gnd

Gnd

Gnd

Gnd

NODE 4

Loading...

Loading...