Manitowoc Published 05-09-17, Control # 014-28 1-53

16000 SERVICE/MAINTENANCE MANUAL INTRODUCTION

Hydraulic Cooling Fan

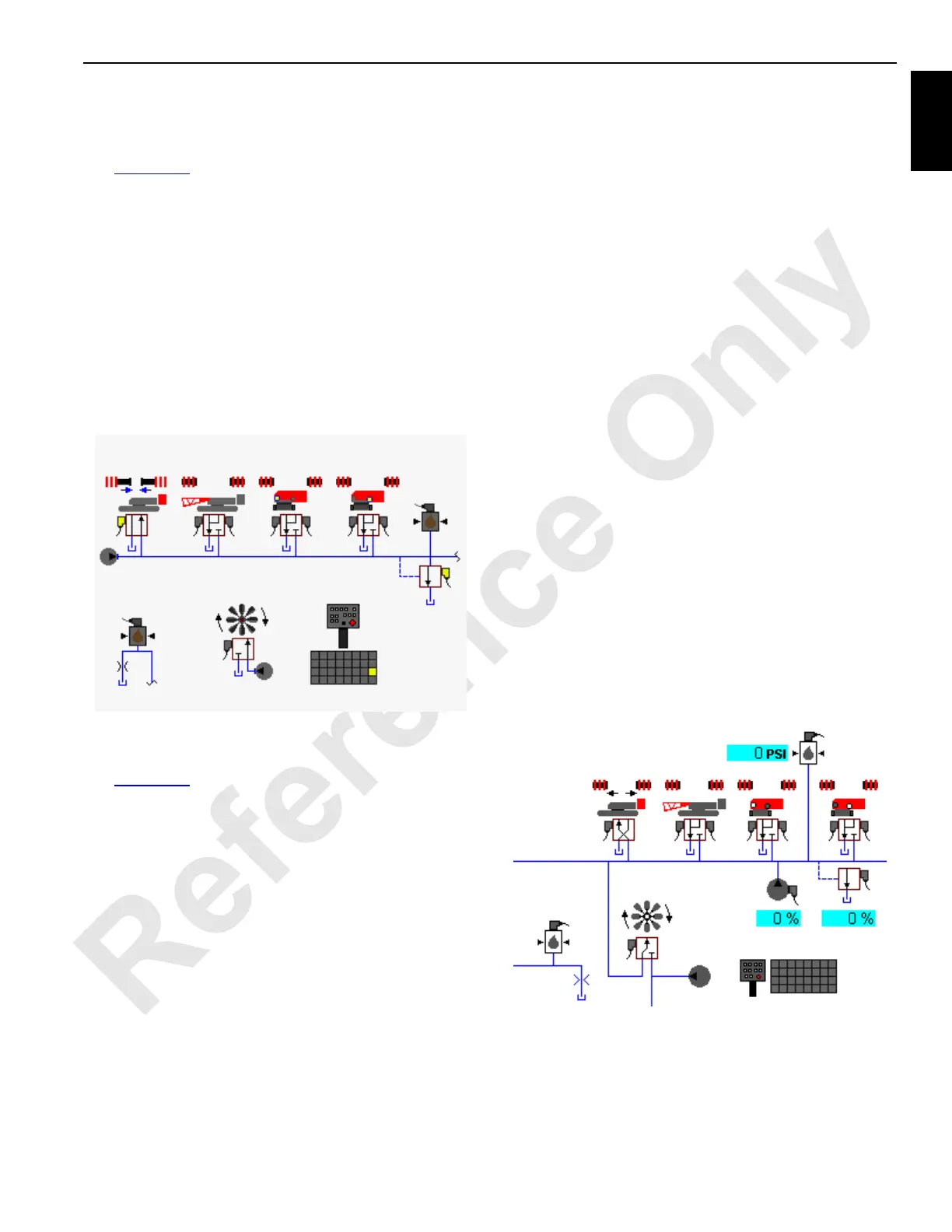

Past Production s/n 16001141 and older

See Figure 1-50 for the following procedure.

The hydraulic cooling fan is fluid driven from the fixed

displacement gear pump mounted on the front of the engine.

The crane controller turns the fan on or off by the normally

closed solenoid operated relief valve set at 3,000 psi (207

bar). When the engine coolant temperature falls to 65°F

(18°C) or if the engine RPM falls below 800, Node-1 disables

the cooling fan by sending a 24 volt signal through Node-5 to

solenoid HS-59. The electric signal causes the relief valve to

vent to tank. The 24 volt signal is removed when the engine

coolant temperature rises to 70°F (21°C) and if the engine

RPM is above 800.

Past Production Cooling Fan Diagnostic Screen:

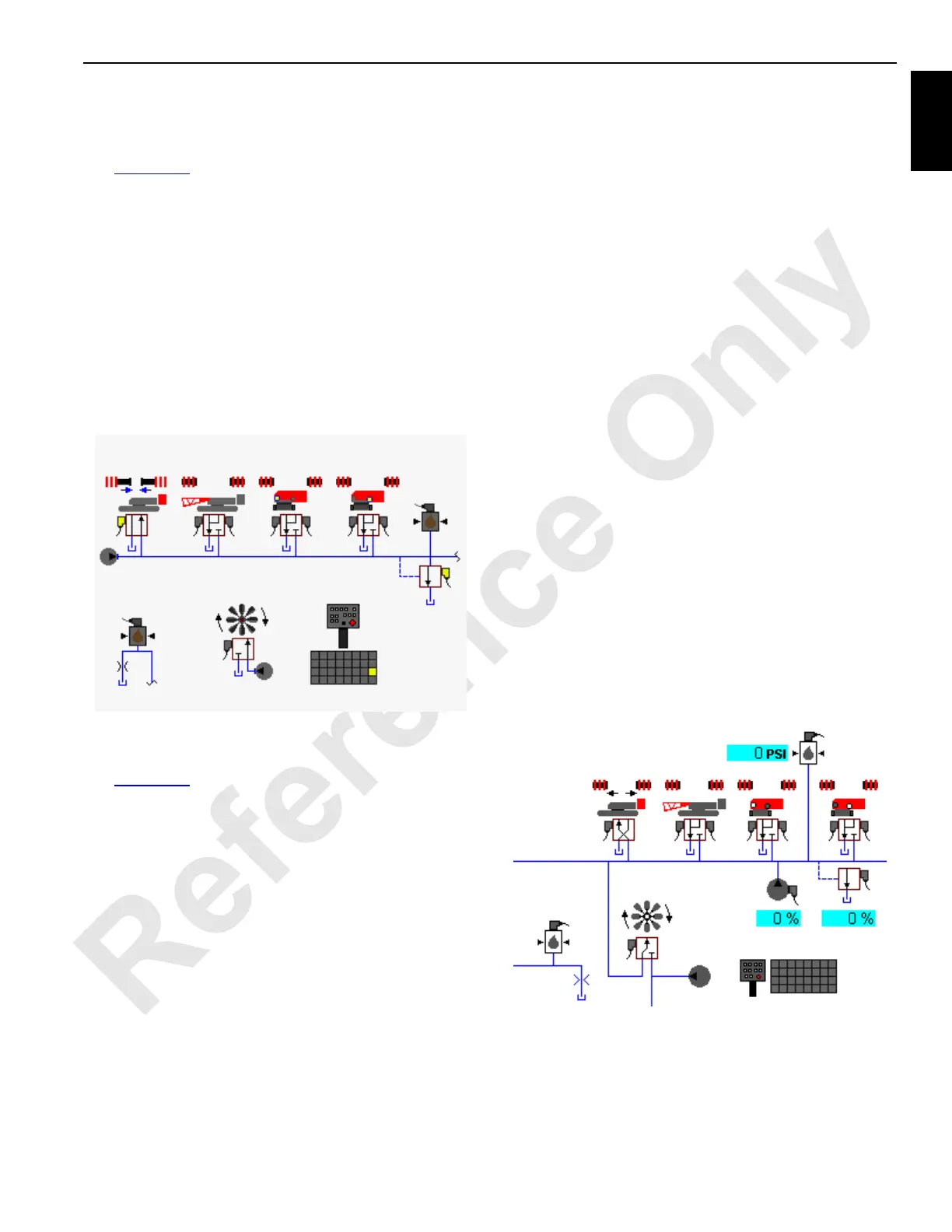

Current Production s/n 16001142 and newer.

See Figure 1-51 for the following procedure.

The hydraulic cooling fan is supplied fluid from either the uni-

directional, variable displacement accessory pump or the

engine-mounted, fixed displacement, lower accessory gear

pump. The accessory system pump will be the main oil

supply to the fan motor until the accessory system is

enabled. Node-1 will send a 24-volt signal through Node-5 to

Solenoid HS-59 shifting the oil supply from the accessory

pump to the lower accessory pump which will supply oil to

the cooling fan. A preset 3,000 psi (207 bar) pressure relief

valve regulates the lower accessory system circuit pressure.

Tier 4 Equipped Machines

Machines equipped with a Tier 4 engine will have a variable

speed cooling fan. The uni-directional, variable displacement

accessory system pump will control the fan RPM in relation

to the feedback of various engine temperature sensors while

the accessory system is disabled. When the accessory

system is enabled, solenoid HS-59 shifts, allowing the lower

accessory system pump to supply oil flow to the fan motor at

a fixed displacement regulated by a 3,000 psi (207 bar) relief

valve.

As engine load increases, the fan speed will also increase to

meet the engine’s cooling needs. Fan speed is determined

by the greatest demand of four inputs: coolant temperature,

air intake temperature (IMT), hydraulic oil temperature and

the state of the air conditioning clutch. The system monitors

these inputs every ten seconds and adjusts the fan speed

depending on the input readings.

A minimum fan speed indicator is included on the Main

display in the cab. The minimum fan speed can be adjusted

but this adjustment should be made only by the

manufacturer. It should not be changed by either the crane

operator or a service technician.

Fan speed should never be 100%. If the actual fan speed

approaches 100%, the operator and/or service person

should investigate to determine the cause of the problem.

NOTE: If there is an electrical failure the fan will default to

high-speed operation only.

A variable-speed fan provides several benefits including

quieter operation, higher efficiency and longer fan life. This

type fan also provides a more uniform engine temperature

and results in more engine horsepower.

See the engine manufacturer’s operating instructions

manual for diagnostic information.

Current Production Cooling Fan Diagnostic Screen:

16-1026

HS-68

Pressure

Sender

Fixed Displacement

gear pump on engine

Lower Accessory

Enable Pressure

Sender

FIGURE 1-50

HS-59

16-1027

HS-68

Pressure

Sender

Lower Accessory Pump

Lower Accessory

Enable Pressure

Sender

FIGURE 1-51

HS-59

Accessory system

pump

Loading...

Loading...