FX3U Series Programmable Controllers

User’s Manual - Hardware Edition

153

9 Preparation for Wiring and Power Supply Wiring Procedures

9.2 Cable Connecting Procedures

1

Introduction

2

Features and

Part Names

3

Product

Introduction

4

Specifications

5

Version and

Peripheral

Devices

6

System

Configuration

7

Input/Output

Nos., Unit Nos.

8

Installation

9

Preparation and

Power Supply

Wiring

10

Input Wiring

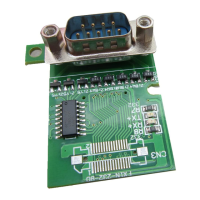

4) Certified connectors (commercially available connectors)

Connectors made by DDK Ltd. shown in Item (3) described in the previous page and connectors made by

Matsushita Electric Works, Ltd. shown in the following table

9.2.3 Terminal block (for europe) [expansion board and special adapters]

The expansion board and special adapters of a terminal block type have terminal blocks for Europe.

1. Applicable products

2. Electric wires

Compliant electric wires and tightening torque

3. Treatment of electric wire ends

Treat the ends of stranded wires and solid wires without coating or using bar terminals with insulating sleeve.

• Treatment of stranded wires and solid wires without coating

- Twist the ends of stranded wires tightly so that loose wires will not

stick out.

- Do not solder-plate the electric wire ends.

Model name of connector

Compliant electric wires

(UL-1061 is recommended)

Pressure bonding tool

Housing AXW1204A

AWG22 (0.3mm

2

)

AWG24 (0.2mm

2

)

AXY52000Contact AXW7221

Semi-cover AXW62001A

WIRING PRECAUTIONS

• Cut off all phases of the power source externally before installation or wiring work in order to avoid electric shock

or damage of product.

• Observe the following items to wire the lines to the European terminal board. Ignorance of the following items may

cause electric shock, short circuit, disconnection, or damage of the product.

- The disposal size of the cable end should follow the dimensions described in this manual.

- Tightening torque should be between 0.22 to 0.25 N

•

m.

- Twist the end of strand wire and make sure there is no loose wires.

- Do not solder-plate the electric wire ends.

- Do not connect electric wires of unspecified size or beyond the specified number of electric wires.

- Fix the electric wires so that the terminal block and connected parts of electric wires are not directly stressed.

Classification Model names

Expansion Board FX

3U-485-BD

Special Adapters

FX

3U-485ADP, FX3U-4AD-ADP, FX3U-4DA-ADP, FX3U-4AD-PT-ADP, FX3U-4AD-TC-ADP,

FX

3U-4HSX-ADP, FX3U-2HSY-ADP

Electric wire size

(stranded wire/solid wire)

Tightening

torque

End treatment

One electric wire

0.3mm

2

to 0.5mm

2

(AWG22 to 20)

0.22 to 0.25N•m

• Remove the coating of the stranded wire, twist

the core wires, and connect the wires directly.

• Remove the coating from the solid wire, and

connect the wire directly.

Two electric

wires

0.3mm

2

(AWG22)

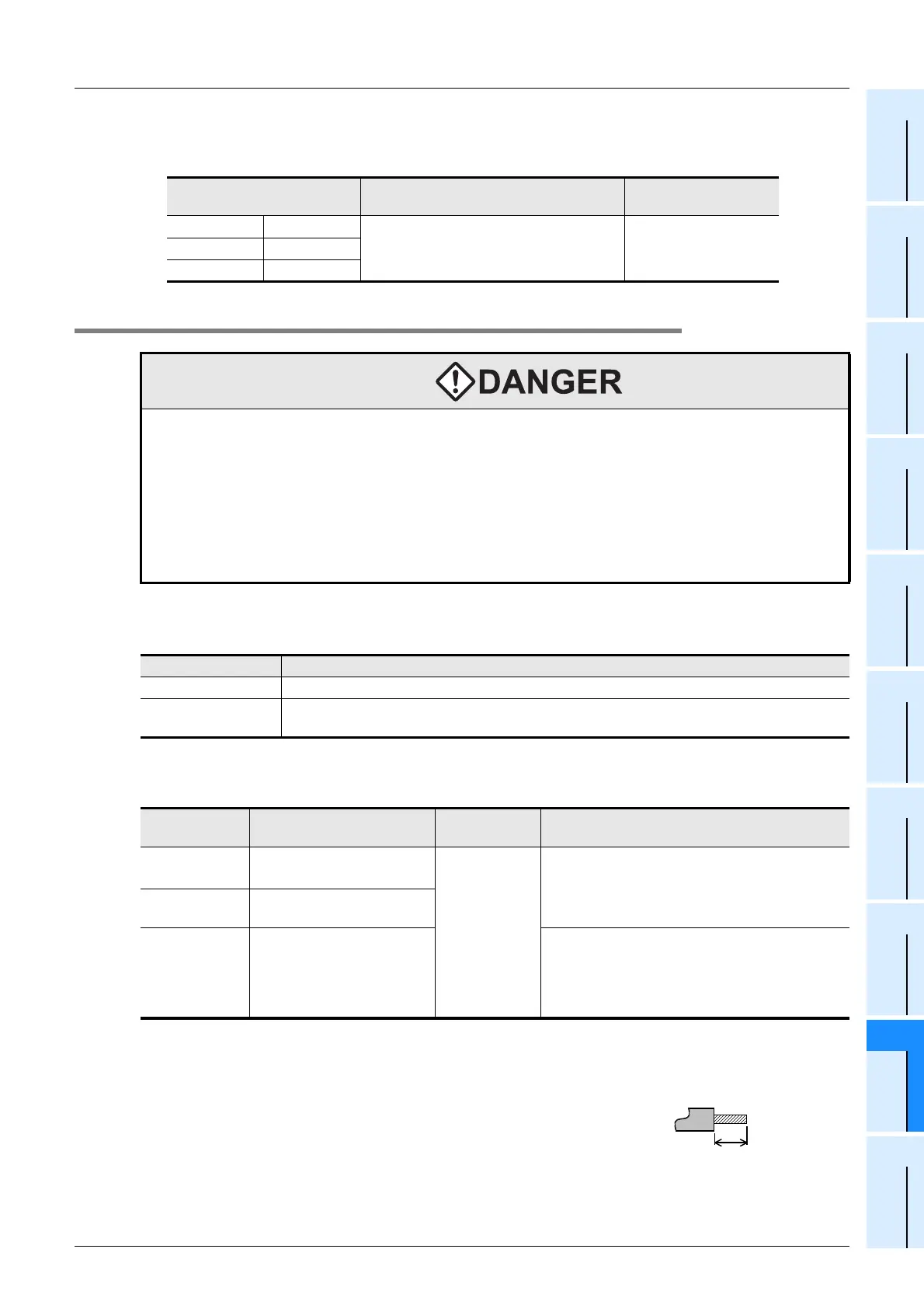

Bar terminal with

insulating sleeve

0.3 mm

2

to 0.5 mm

2

(AWG22 to 20)

(Refer to the following outline

drawing of bar terminal.)

• Bar terminal with insulating sleeve

(recommended product)

AI 0.5-8WH (Phoenix Contact)

• Caulking tool

CRIMPFOX UD6 (Phoenix Contact)

9mm

(0.36")

•

Stranded wire/solid wire

Loading...

Loading...