Do you have a question about the Mitsubishi FX3U-20SSC-H and is the answer not in the manual?

| Number of Axes | 2 |

|---|---|

| Maximum Output Pulse Frequency/Speed | 200 kHz |

| Compatible PLC | Mitsubishi FX3U |

| Positioning Command | Absolute/Relative |

| Power Supply Voltage | 5V DC (supplied from main unit) |

| Dimensions | 90 x 55 x 87 mm (W x H x D) |

Critical safety precautions for installation to prevent severe injury or death from incorrect handling.

Safety precautions to prevent medium or slight personal injury or physical damage from incorrect handling.

Safety precautions for wiring to prevent medium or slight injury or damage from incorrect handling.

Safety measures for startup and maintenance to prevent severe injury or death.

Details about registered trademarks and company product names.

Information on UL, cUL, and EC directive compliance, including EMC directives.

Explains how to use the manual and its relationship with other manuals.

Lists related manuals for PLC units, programming, and servo amplifiers.

Defines generic terms and abbreviations used throughout the manual.

Explains how to navigate and understand the manual's structure.

Provides a general overview of the positioning block and its features.

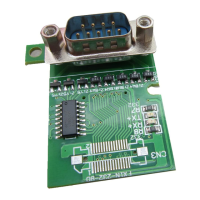

Details the physical dimensions and identifies key parts of the unit.

Explains the function and status indications of the unit's LEDs.

Provides a general overview of the system configuration with a block diagram.

Explains how to connect the 20SSC-H to a PLC and the maximum connectable units.

Lists the PLC models compatible with the 20SSC-H.

Covers general specifications such as dielectric withstand voltage and insulation resistance.

Specifies the external and internal power supply requirements.

Outlines performance aspects such as control axes and backup capabilities.

Details the electrical specifications for all input signals.

Shows pin assignments for input and power connectors.

Describes the procedure for mounting the unit onto a DIN rail.

Details the procedure for direct mounting using screws.

Lists required cables, connectors, and wire sizes for system connections.

Instructions for correctly wiring the power supply.

Instructions for connecting input signals to the unit.

Guides on connecting the SSCNET III cable.

Describes the unit's memory structure and its role in operations.

Outlines the procedures for transferring data between system components.

Critical notes and guidance for setting positioning and servo parameters.

Describes the general principles and relationships in positioning operations.

Explains the function and handling of rotation limit switches.

Describes how the STOP command functions during positioning operations.

Explains how to configure sudden stop behavior based on various conditions.

Details dynamic changes to operation speed and target address.

Details selecting acceleration/deceleration times for positioning operations.

Explains configuring ring operation for current address.

Covers various other functions available with the 20SSC-H.

Provides important cautions related to positioning operations.

Explains the process and types of mechanical zero return operations.

Covers the JOG operation mode for manual control.

Describes manual pulse generator operation.

Summarizes functions available for each positioning operation type.

Explains the 1-speed positioning operation procedure.

Details the interrupt 1-speed constant quantity feed operation.

Covers the 2-speed positioning operation, including target addresses and speeds.

Describes the interrupt 2-speed constant quantity feed operation.

Explains how to perform an interrupt stop during positioning.

Details the variable speed operation mode.

Covers multi-speed operation, especially in table operations.

Explains linear interpolation for coordinated axis movement.

Details linear interpolation with interrupt stop functionality.

Describes circular interpolation for curved path movements.

Explains the reciprocal movement instruction for back-and-forth motion.

Overview of table operation, including applicable functions.

Guides on setting table information via sequence program or FX Configurator-FP.

Shows BFM number allocation for table operation information.

Outlines the step-by-step procedure for executing table operations.

Explains continuous pass operation for sequential interpolation.

Lists positioning parameters for setting speed and units.

Covers various parameters for servo amplifier configuration.

Explains how to monitor operating conditions and data.

User-specified data for controlling the positioning system.

Explains how to read and write data to the buffer memory.

Lists device assignments for inputs and outputs.

Explains mechanical zero return for X-axis and Y-axis.

Explains the 1-speed positioning operation.

Describes an example sequence program.

Explains how to check the status of the unit's LEDs.

Lists and explains error codes and actions.

Diagnosing PLC main unit issues via LED indicators.

Lists monitor data BFMs, descriptions, and references.

Details control data BFMs, settings, and references.

Lists table information items, BFM numbers, and descriptions.

A comprehensive list of positioning parameters.

A detailed list of servo parameters.

General version information.

Explains how to check the product's version.

Details the history of version upgrades and added functionalities.