Troubleshooting

216 0112-0109 H

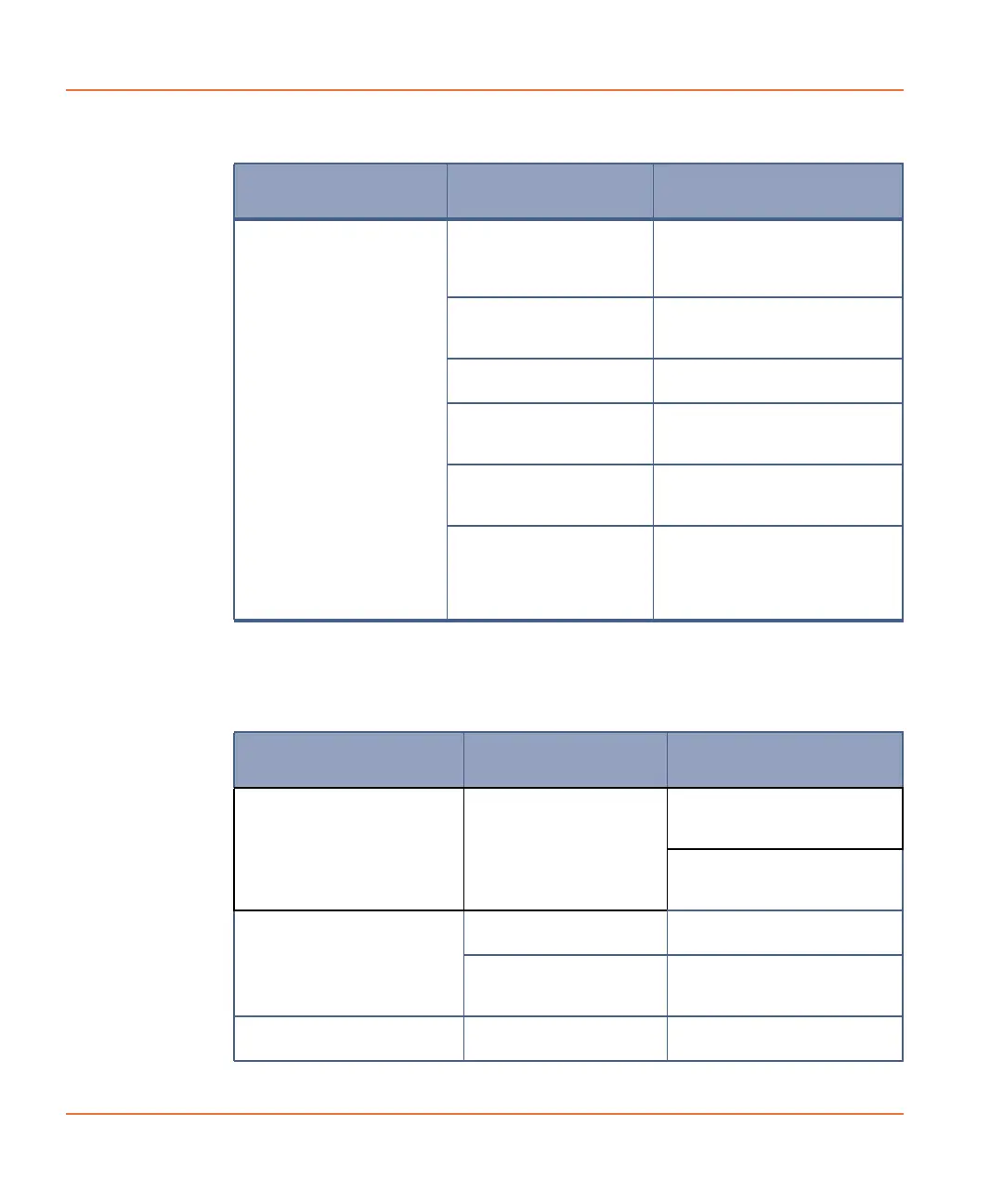

Troubleshooting the Tip Washer

Standard deviation for

the signal test is

greater than 5% and

fluorescence counts

may or may not be in

the correct range.

Instrument was

calibrated with yellow

boat.

If instrument was calibrated

using the yellow boat, the

standard deviation can be

5% or less.

Camera not fully

cooled down.

Wait approximately 10

minutes for the camera

temperature to cool down.

Optical correction out

of specifications.

Perform Flat-Field

calibration.

Plate is not aligned

properly in Read

position.

Make sure plate is properly

aligned and indexed in the

Read position.

Optics is dirty or

failing.

Contact Technical Support

at

+1-800-635-5577.

Calibration plate

failure— plate is dirty

or scratched.

Clean calibration plate with

lens paper. DO NOT use lab

wipes. If cleaning does not

work, replace the calibration

plate.

Table 9-6 Troubleshooting the Yellow Plate (cont’d)

Symptom or Error

Message

Possible Causes Solutions

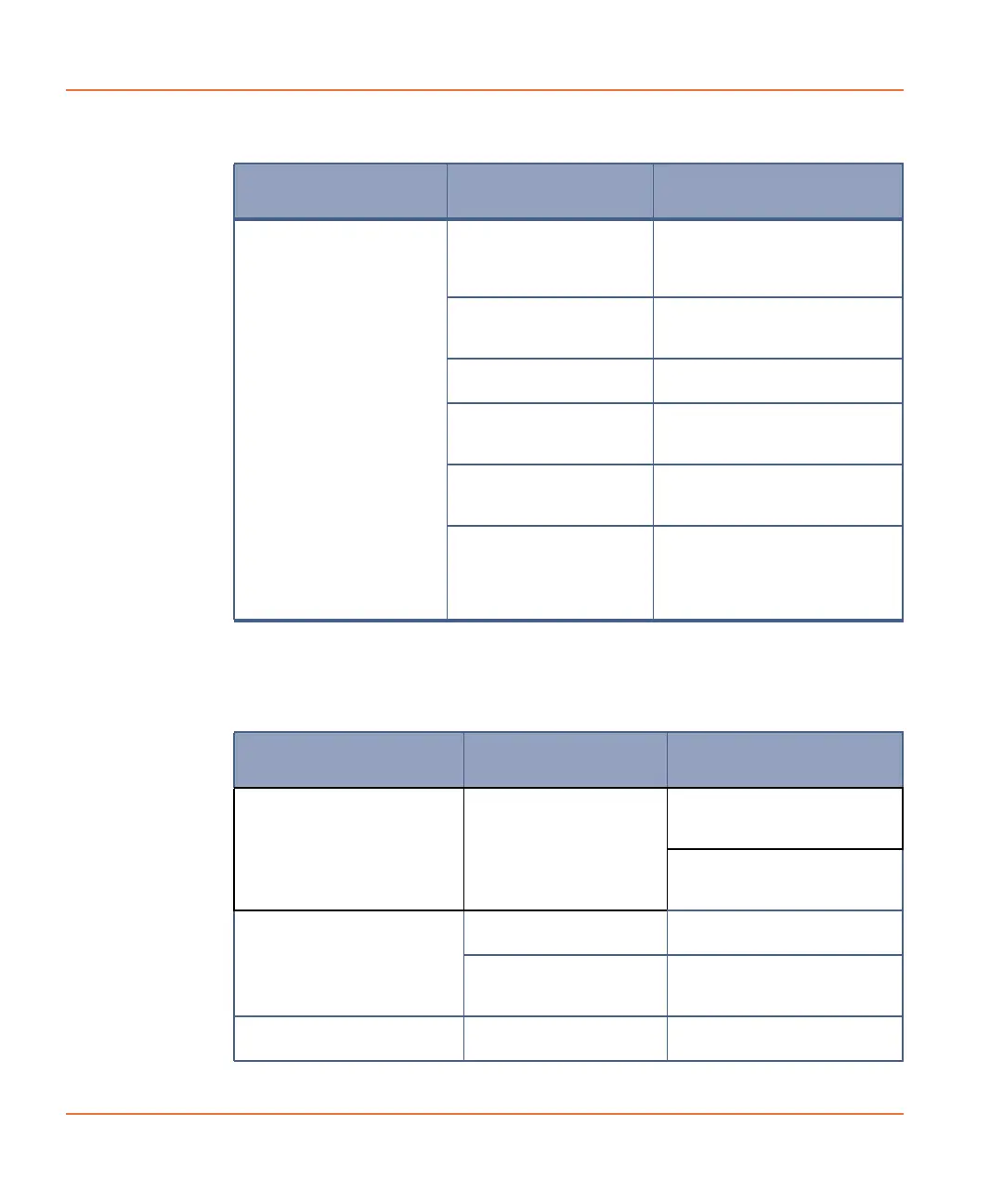

Table 9-7 Troubleshooting the Tip Washer

Symptom or Error

Message

Possible Causes Solutions

221: “Tip wash reservoir

format (96/384/1536)

does not match pipettor

head. Please install

matching reservoir and

select Reset.”

Pipettor head and tip

washer reservoir top

do not match (e.g., a

384 Pipettor head with

a 96-well reservoir

top).

Install appropriate

pipettor head to match tip

wash reservoir top.

Install appropriate tip

wash reservoir top to

match pipettor head.

222: “Tip wash reservoir

top not detected. Please

install matching reservoir

and select Reset.”

No reservoir top is

installed.

Install appropriate tip

wash reservoir top.

Tip wash reservoir top

is not properly

installed.

Tip wash reservoir top

connectors may not be

properly connected.

223: “Check Waste Bottle

A - sensor indicates full.”

Waste bottle A is full

with tip wash solvent.

Empty tip wash solvent

from waste bottle A.

Loading...

Loading...