System Hardware Features

28 0112-0109 H

revolution per second. From the uniform suspension in the spinner flask

cells are pumped into the Cell Reservoir, where the pipettor head in 96,

384, or 1536 format removes the appropriate amount and cells are

automatically pumped to a specified destination. A protocol in

ScreenWorks Software controls the stir speed and source/destination of

cell suspension activity.

The cell valve selects the source for filling, or the destination for

draining. There are 8 valve positions: flask fill (for filling the reservoir),

flask drain (for draining the reservoir without causing air bubbles),

Waste Bottle A, Waste Bottle B, and Fluid 1–4.

Fluid 1–4 are user specifiable, and can be cleaning solutions, water or

buffer. The user can choose to pump cells back into the cell flask or to

any other fluid bottles. Bottles for Fluid 1 and 2 are automatically

included with the Cell Suspension option.

Cell Reservoir can be washed by either adding the Wash Reservoir

process to the protocol (see Constructing Protocols Using FLIPR Tetra

Processes on page 70), selecting Wash Reservoir in the Instrument

> Manual Operation menu, or manually removing the reservoir and

autoclaving it.

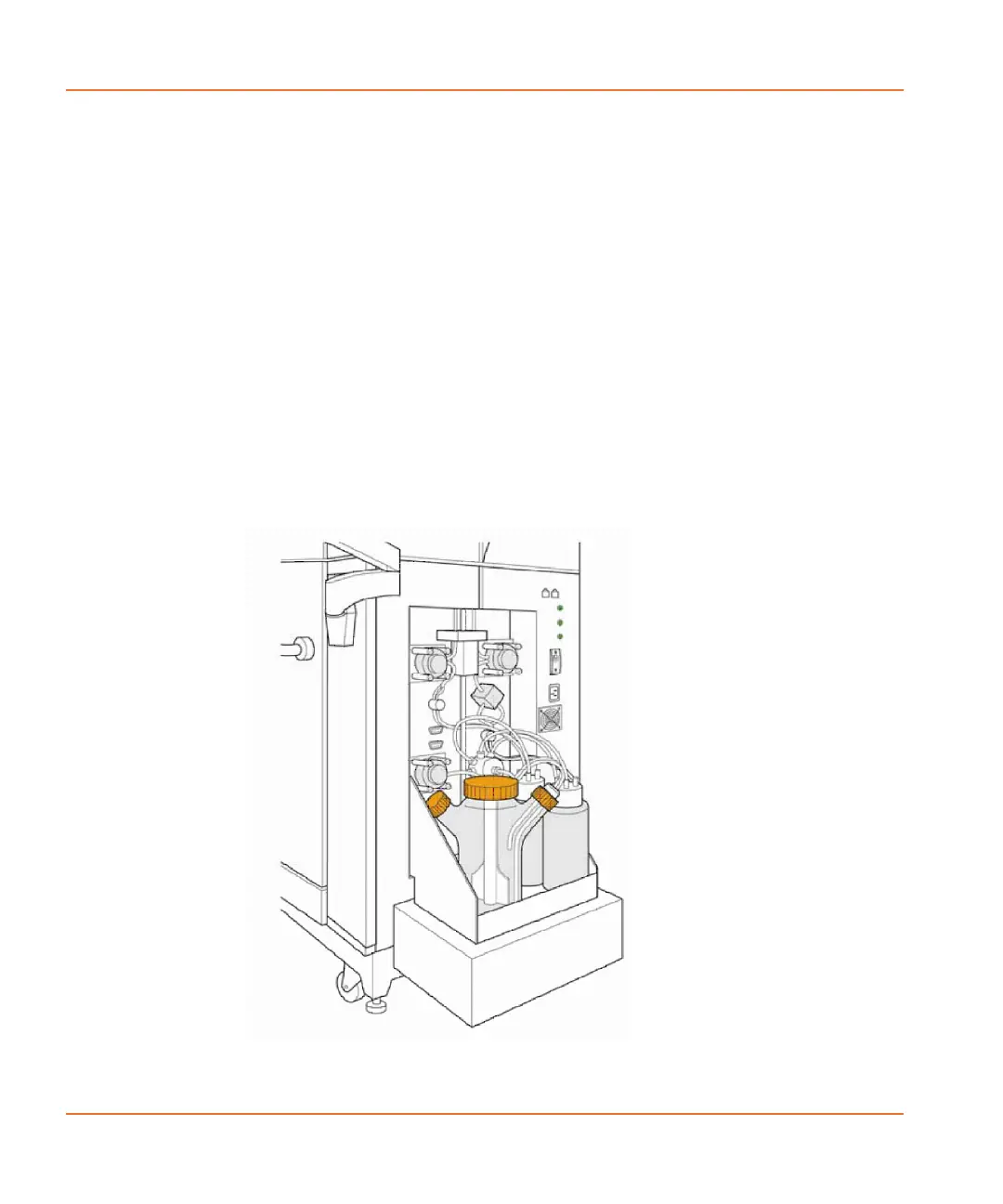

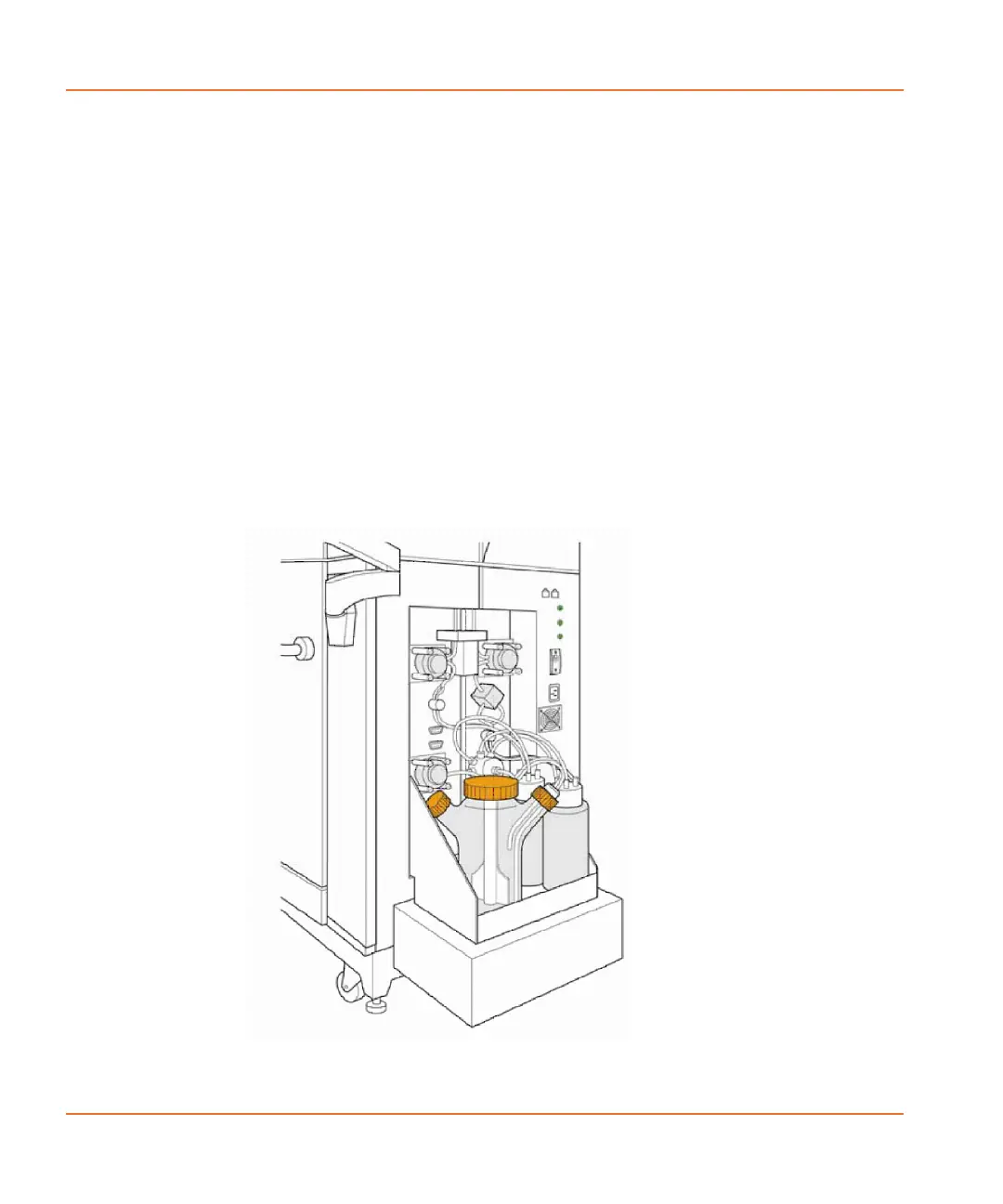

Figure 2-6 Cell Suspension Module.

Loading...

Loading...