Oki Data CONFIDENTIAL

3. MAINTENANCE MENUS

45762101TH Rev.1

3-27

3.6 Settings after Parts Replacement

The necessary adjustments after the parts exchange are explained as follows.

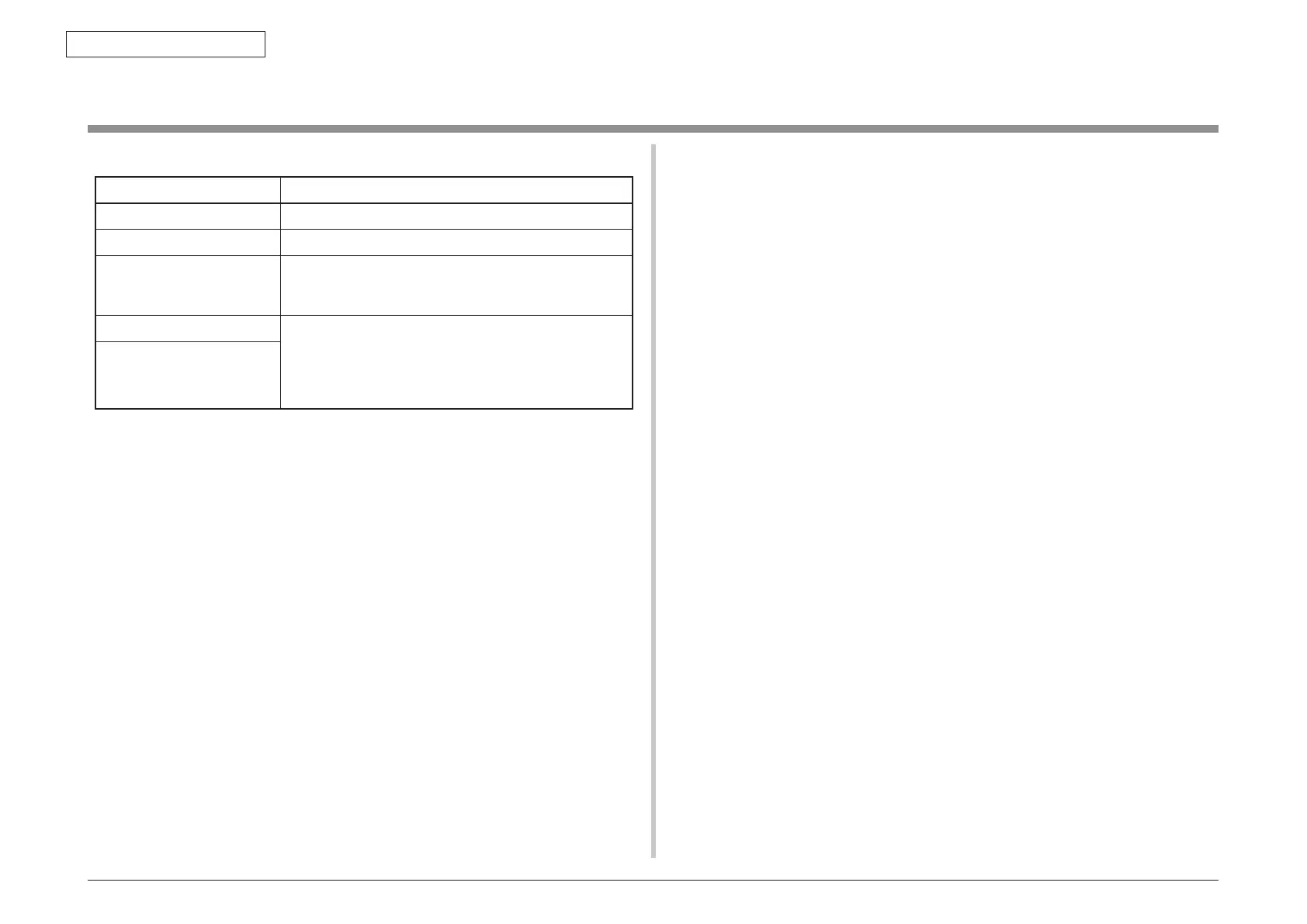

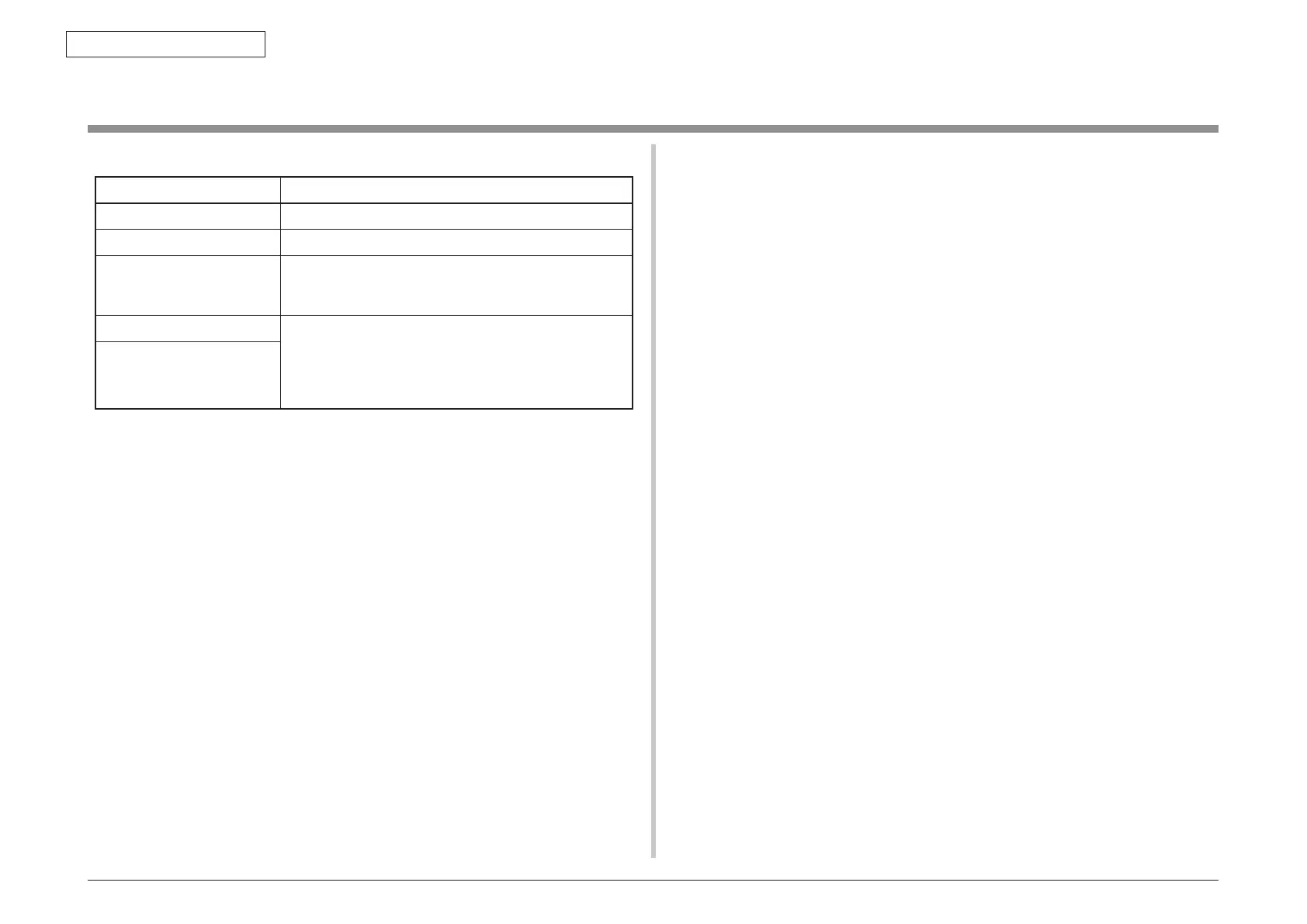

Replaced Part Adjustment

LED Head Not required.

Image Drum Cartridge Not required.

Main (CU/PU board (MRM))

Copy the EEPROM information; utility is required.

Upgrade firmware by Firmware suite. See 6.3 Firm-

ware Information.

SU board (MSU)

Copy the setting parameter of Scanner; utility is

required.

Setup of Country Code for Fax (mandatory).

Upgrade firmware by Firmware suite. See 6.3 Firmware

Information.

Scanner Unit

(Maintenance)

3.6.1 Notes on CU/PU board (MRM) replacement

1. When the EEPROM on a board to remove can be accessed (when SERVICE

CALL 104 [Engine EEPROM Error] or 40 [EEPROM Error] is not displayed):

(1) Remove information from the EEPROM in the PU block, and setting information

from the EEPROM in the CU block, of the board, and temporarily store them

onto an HDD of a computer, by using the board replacement function of

Maintenance Utility (Refer to Maintenance Utility Operating Manual, about

Board Replacement).

(2) By using the board replacement function, copy the information and setting

information into the EEPROM of a board to replace with.

(3) When only the information or setting information can be removed from the

board to replace, copy it into the EEPROM of the replacement board by

using the board replacement function. With the board replacement function,

separately configure the other information, which cannot be removed. Perform

PU-block serial-number setting (Refer to Maintenance Utility Operating Manual,

about Serial number setting), and make a change to the Shipping mode

(Refer to Maintenance Utility Operating Manual, about Factory / Shipping

mode setting), in setting windows when the information cannot be removed.

Configure CU-block serial number information (Refer to Maintenance Utility

Operating Manual, about Serial number setting) when the setting information

cannot be removed.

Note! When removing or writing information from/into the EEPROM by using

Maintenance Utility, use the procedure shown below to place the printer to

the Forced ONLINE mode before accessing the EEPROM. Even in the forced

ONLINE mode, the printer provides an error indication when having an error.

1. The printer displays ONLINE when operating properly, and provides an

error indication when having an error, where the printer is internally online,

being ready to communicate.

2. When the EEPROM on a board to remove cannot be accessed:

When the operator panel displays SERVICE CALL 104 (Engine EEPROM Error)

for, or data cannot be read from the EEPROM of, a board to remove, follow the

following procedure to perform operation by using Maintenance Utility after the

board is replaced with a new one:

(1) [When facing OEL]

(1-1)Set the PU serial number

(Refer to Maintenance utility operation manual, about Serial number

setting)

SAP serial number can be applied to the device. The SAP serial

number is displayed in the highest rung of the serial number label. It

is a 12-digit number including production place (2 digits), production

year (2 digits), sequence number (6 digits) and revision number (2

digits).

• PU serial number is a 10-digit number which is basically the same

as SAP serial number except that it has no the 2-digit revision

number.

• Set on the menu of [Serial number setting].

Loading...

Loading...