45762101TH Rev.1

2-55

2. TROUBLESHOOTING PROCEDURES

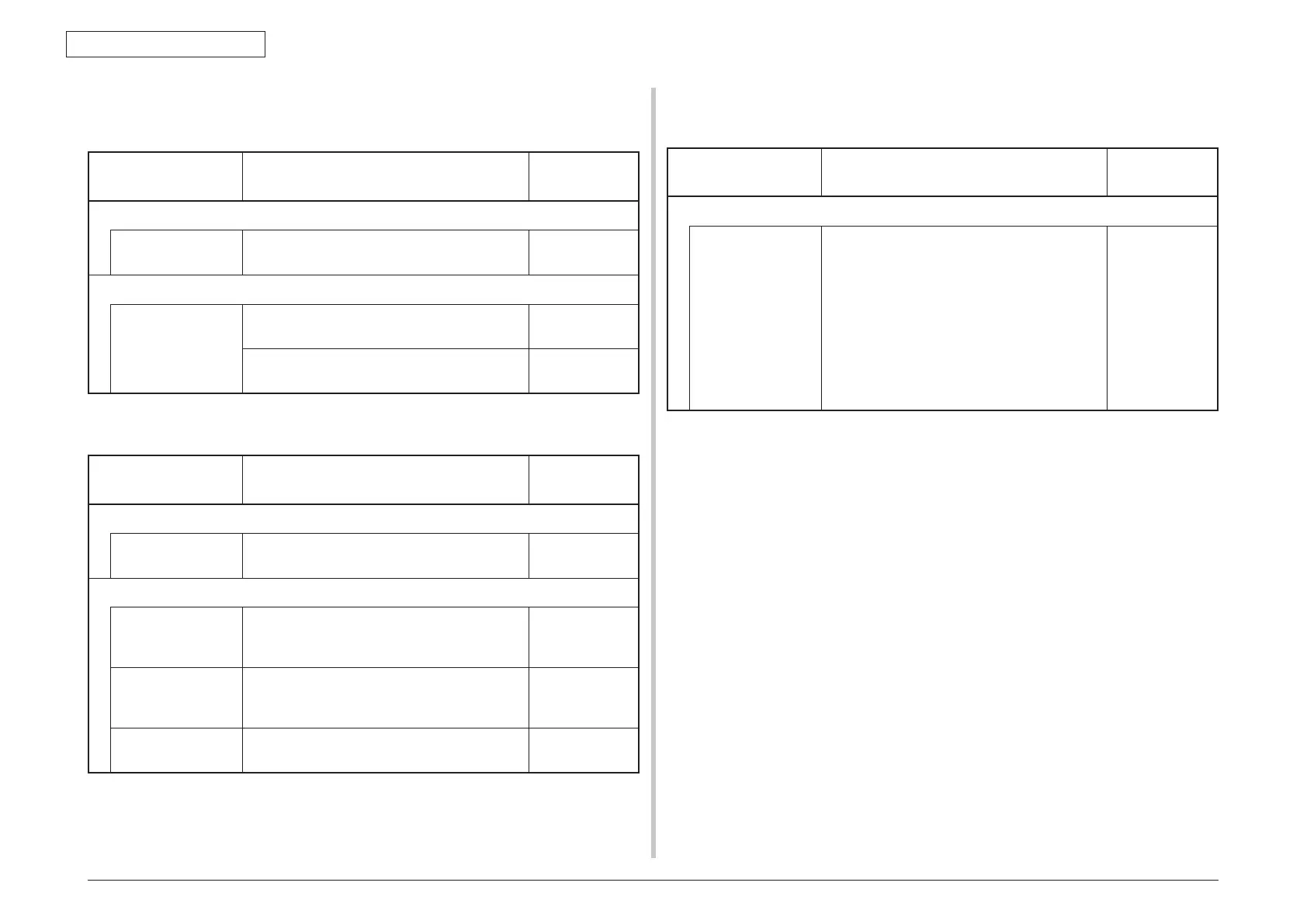

2.5.5. (6) Paper running jam (Error code: 381)

(6-1) Jam occurs immediately after the power is turned on.

Check item Check operation

Actions for NG

results

(6-1-1) Check condition of paper running path

Paper running path

of the ejection unit

Open the rear cover and top cover check if paper

is not jammed in the paper running path.

Remove the

paper

(6-1-2) Check condition of the mechanical parts

Ejecting sensor Does the ejecting sensor lever work normally?

(It moves freely by touching.)

Replace the

ejecting sensor.

Clean a sensor. Replace the main

board.

(6-2) Jam occurs immediately after the paper feed is started.

Check item Check operation

Actions for NG

results

(6-2-1) Check condition of paper running path

Paper running path

of the ejection unit

Open the rear cover and top cover check if paper

is not jammed in the paper running path.

Remove the

paper

(6-2-2) Check condition of the mechanical parts

Paper ejection roller Is the paper ejection roller appropriately

installed?

Install the paper

ejection roller

appropriately.

Paper ejection

spring

Is the paper ejection spring appropriately

installed?

Install the paper

ejection spring

appropriately.

Cover-Assy Rear or

fuser unit Assy.

Replace Cover-Assy Rear. Replace fuser

unit Assy.

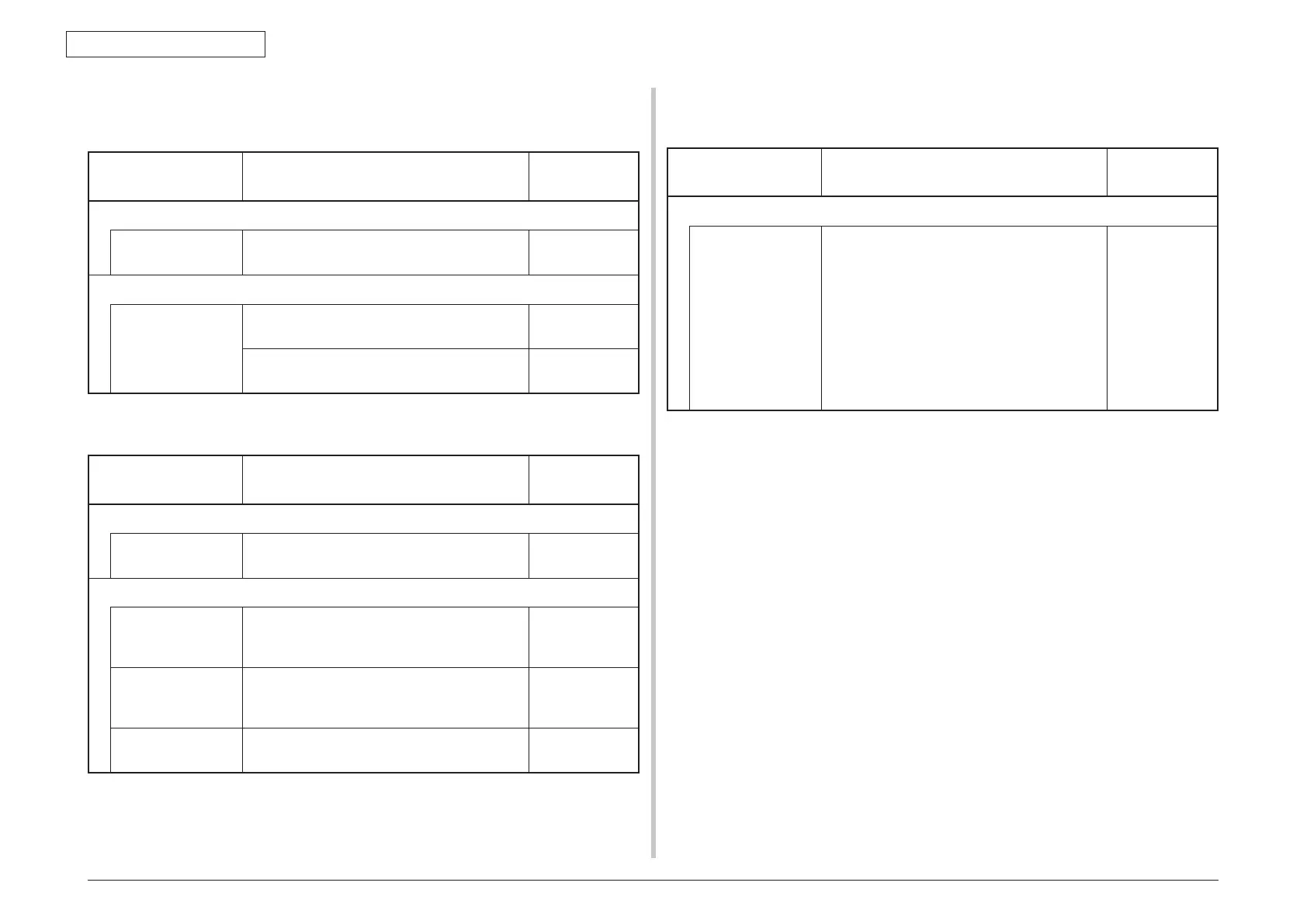

2.5.5. (7) Two-sided printing jam (Error code: 372)

(7-1) Two-sided printing jam.

Check item Check operation

Actions for NG

results

(7-1-1) Check condition of the paper running path

Paper running path

of the Duplex unit

Check if paper is jammed or not in the paper

running path.

Open the front cover and check if any paper

remains in the Duplex feeder or not.

Open the rear cover and check if any paper

remains in the paper reversing path or not.

Remove the Duplex unit. Check if any paper

exists in the Duplex insertion slot or not. Open

the cover of the Duplex paper running path and

check if any paper remains inside of the Duplex

unit.

Remove the

jammed paper.

Loading...

Loading...