4-22

4-2 Function Mode

4

Functions

PID Function

This function enables process control of such elements as flow rate, air volume, and pressure.

•To use this function, set A071 to 01.

•To switch between enable/disable via the terminal block (external signal), allocate 23 (PID enable/

disable) to the desired multi-function input. Select OFF for enable and ON for disable.

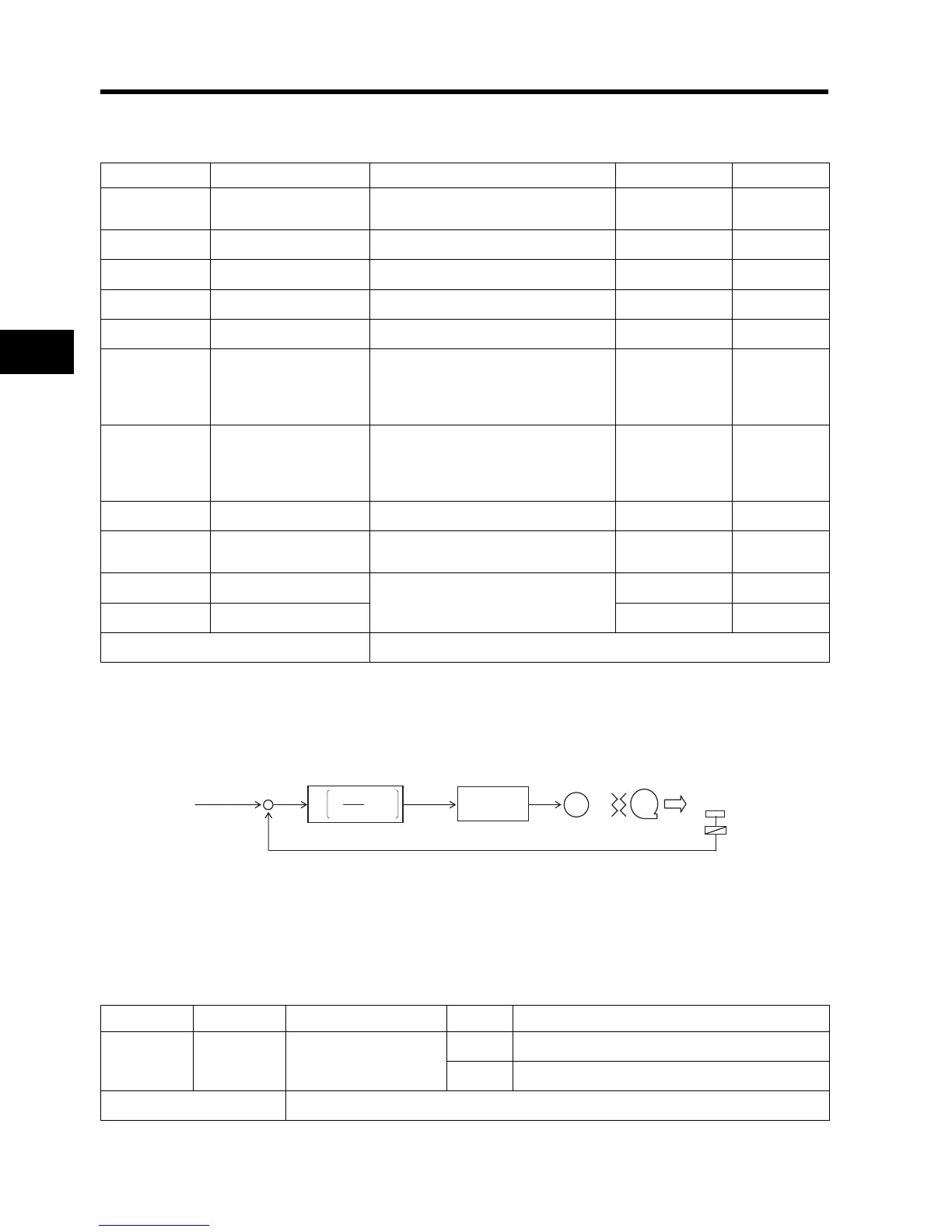

Basic Structure of PID Control (Example)

PID Enable/Disable

The PID enable/disable function disables the PID function temporarily through terminal input. This

overrides the A071 setting to control the motor frequency.

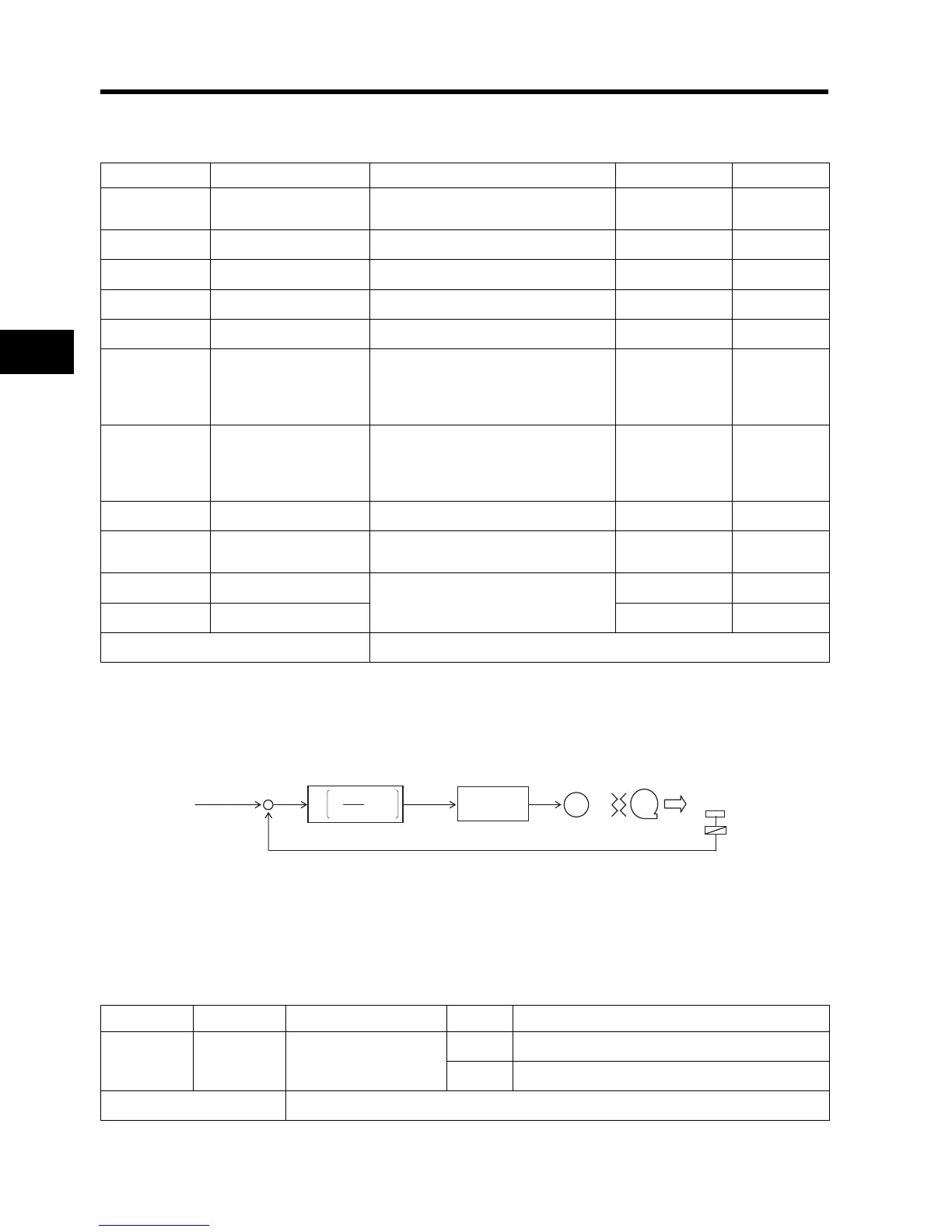

Parameter No. Function name Data Default setting Unit

A071 PID selection

00: Disabled

01: Enabled

00 ⎯

A072 PID P gain 0.2 to 5.0 1.0 ⎯

A073 PID I gain 0.0 to 150.0 1.0 s

A074 PID D gain 0.00 to 100.0 0.0 s

A075 PID scale 0.01 to 99.99 1.00 Time

A076 PID feedback selection

00: OI

01: O

02: RS485 communication

03: Operation function output

00 ⎯

A077 Reverse PID function

00: Deviation = Target value -

Feedback value

01: Deviation = Feedback value -

Target value

00 ⎯

A078 PID output limit function 0.00 to 100.0 0.0 %

C044

PID deviation excessive

level

0. to 100. 3.0 %

C052 PID FB upper limit

0.0 to 100.0

100 %

C053 PID FB lower limit 0.0 %

Related parameters d004, A001, A005, C001 to C005, C021, C026

fs

M

=

+

-

Deviation ε

ε: Deviation

sT

sT

K

d

i

p

1

1

Target value

0 to 10 V

4 to 20 mA

+

·

·

+

Control

value

Feedback 0 to 10 V

4 to 20 mA

Normal control

of the Inverter

Transducer

Sensor

Kp: Proportional gain Ti: Integral time Td: Derivative time s: Operator

Data Symbol Function name Status Description

23 PID PID enabled/disabled

ON Disables the PID function.

OFF Does not affect the PID function.

Related parameters

C001 to C005

Loading...

Loading...