777

Data Control Instructions Section 3-18

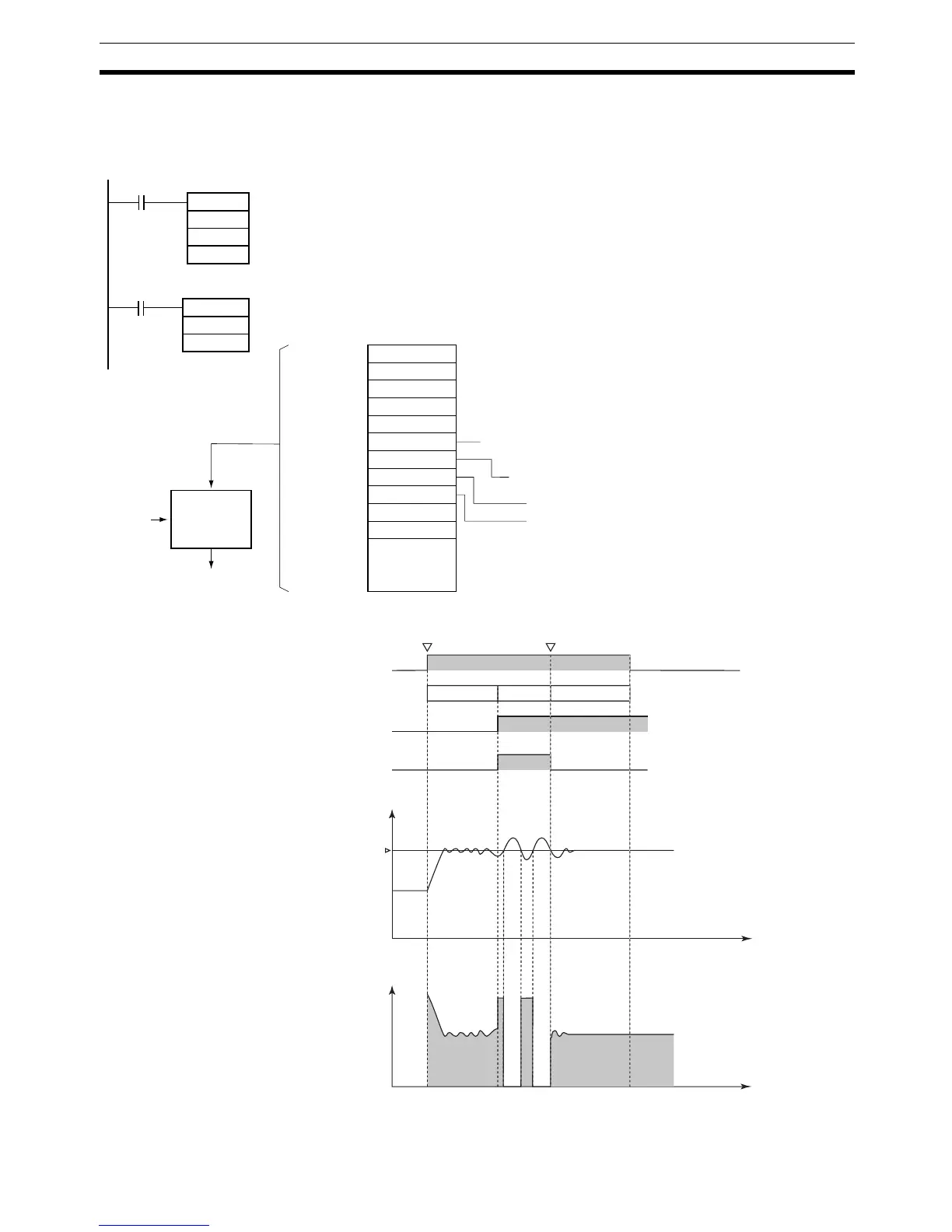

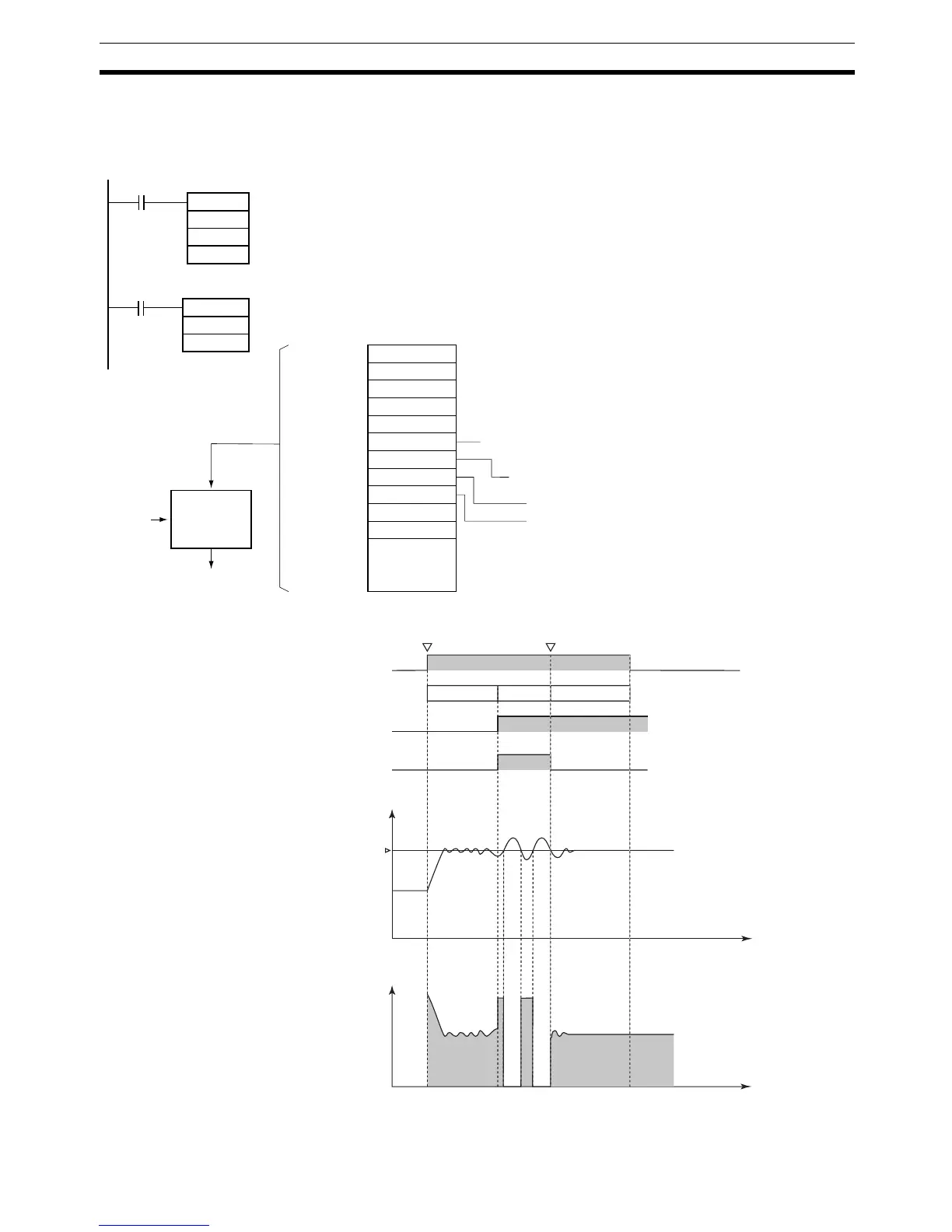

At the rising edge of W 000000 (OFF to ON), SETB(532) turns ON bit 15 of

D00209 (C+9) and starts autotuning. When autotuning is completed, the cal-

culated P, I, and D constants are written to C+1, C+2, and C+3. PID control is

then restarted with the new PID constants.

PIDAT

0010

D00200

0020

000000

S

C

D

C: D00200

C+1: D00201

C+2: D00202

C+3: D00203

C+4: D00204

C+5: D00205

C+6: D00206

C+7: D00207

C+8: D00208

C+9: D00209

C+10: D00210

C+11: D00211

C+40: D00240

012C

0064

04B0

0190

0032

0000

0494

0000

0000

0000

0000

W00000

SETB

D00209

#000F

Work area

Proportional band: 10.0%

Integral time: 120.0 s

Derivative time: 40.0 s

Sampling

period: 0.5 s

Reverse operation (bit 00: 0), PID constant change enable setting =

OFF (bit 01: 0), set value = manipulated variable output 50% (bit

03: 1), 2-PID parameter = 0.65 (bits 04 to 15: 000 hex)

Manipulated variable output range: 12 bits (bits 00 to 03: 4 hex),

Integral/derivative constant: time designation (bits 04 to 07: 9 hex)

Input range: 12 bits (bits 08 to 11: 4 hex),

Manipulated variable output limit control disabled (bit 12: 0)

AT Command Bit OFF (bit 15: 0),

AT Calculation Gain = 1.00 (bits 00 to 11: 000 hex)

Limit-cycle Hysteresis = 0.20%

PID starting integral manipulated variable

designation = start from same integral

manipulated value as manipulated variable

output designation (bit 14: 0 and bit 13: 0)

Parameters

PV:

CIO 0010

MV output: CIO 0020

to

PID calculation

Set value: 300

CIO 000000

W000000

PV

SV

MV

PID control PID control

AT executing

PID control starts.

Calculated PID

constants are set.

Bit 15 of

D00209

Time

Time

Loading...

Loading...