920

Step Instructions Section 3-22

Application Examples The following three examples demonstrate the three types of execution con-

trol possible with step programming. Example 1 demonstrates sequential exe-

cution; Example 2, branching execution; and Example 3, parallel execution.

Example 1:

Sequential Execution

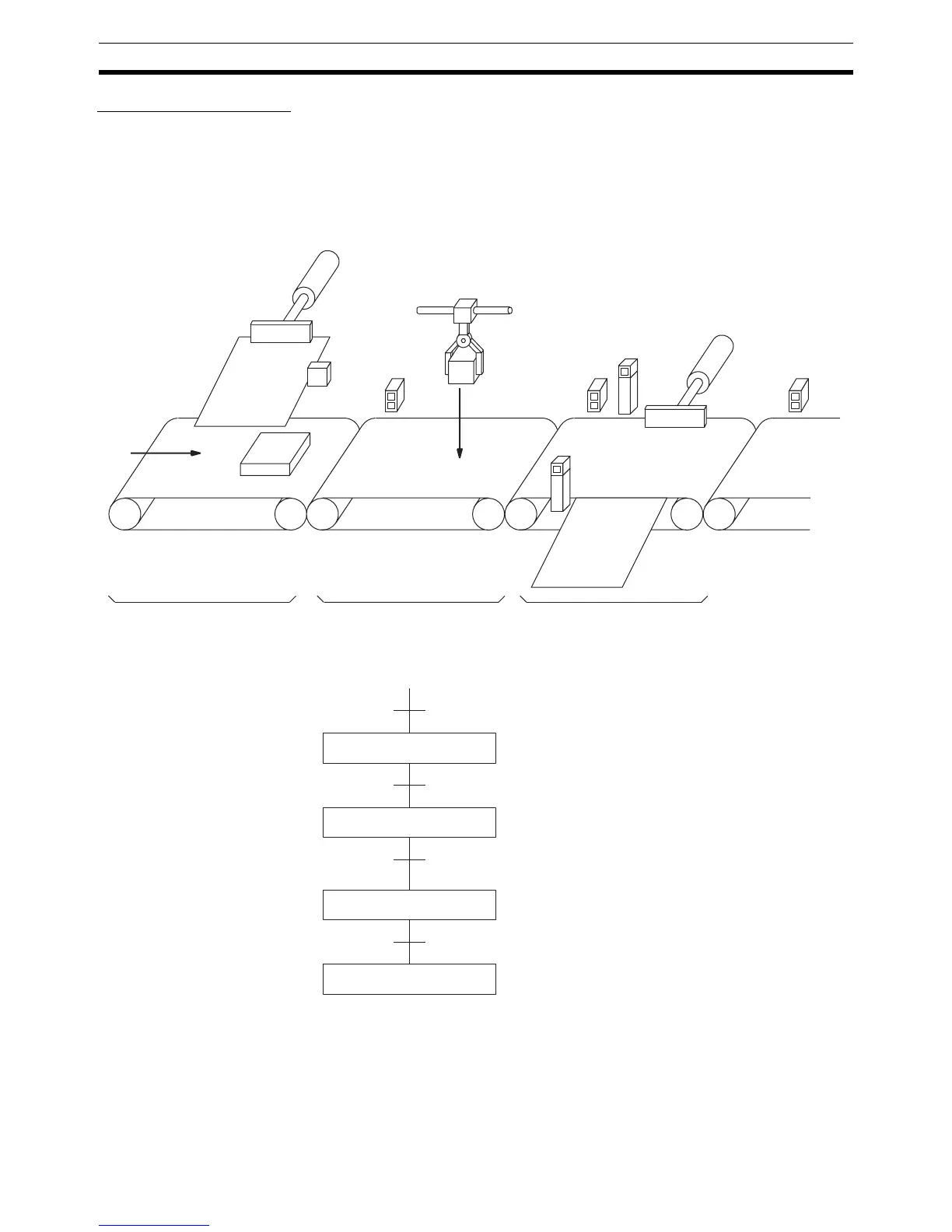

The following process requires that three processes, loading, part installation,

and inspection/discharge, be executed in sequence with each process being

reset before continuing on the next process. Various sensors (SW1, SW2,

SW3, and SW4) are positioned to signal when processes are to start and end.

The following diagram demonstrates the flow of processing and the switches

that are used for execution control.

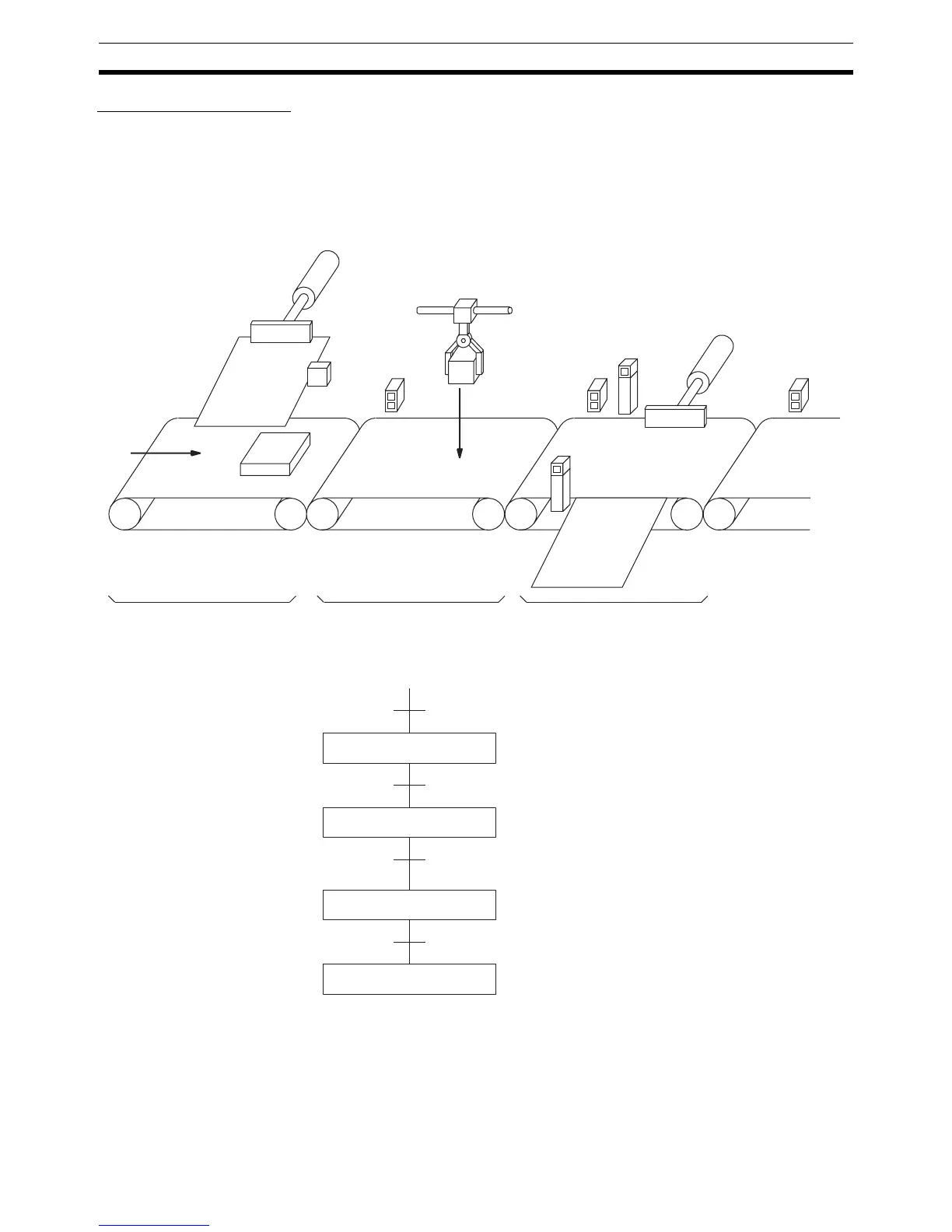

The program for this process, shown below, utilizes the most basic type of

step programming: each step is completed by a unique SNXT(009) that starts

the next step. Each step starts when the switch that indicates the previous

step has been completed turns ON.

SW 1

SW 2

SW 3

SW 4

Solenoid 1

Robot hand

Solenoid 2

Conveyor belt 1

Loading

Conveyor belt 2

Part installation

Conveyor belt 3

Inspection/discharge

Photomicro-

sensor

SW1

SW2

SW3

SW4

Process A

Process B

Process C

Loading

End

Part Installation

Inspection/discharge

Loading...

Loading...