THE NEW PIPER AIRCRAFT, INC.

PA-32-301FT / 301XTC

MAINTENANCE MANUAL

PAGE 4

Jun 1/03

5F16

80-10-00

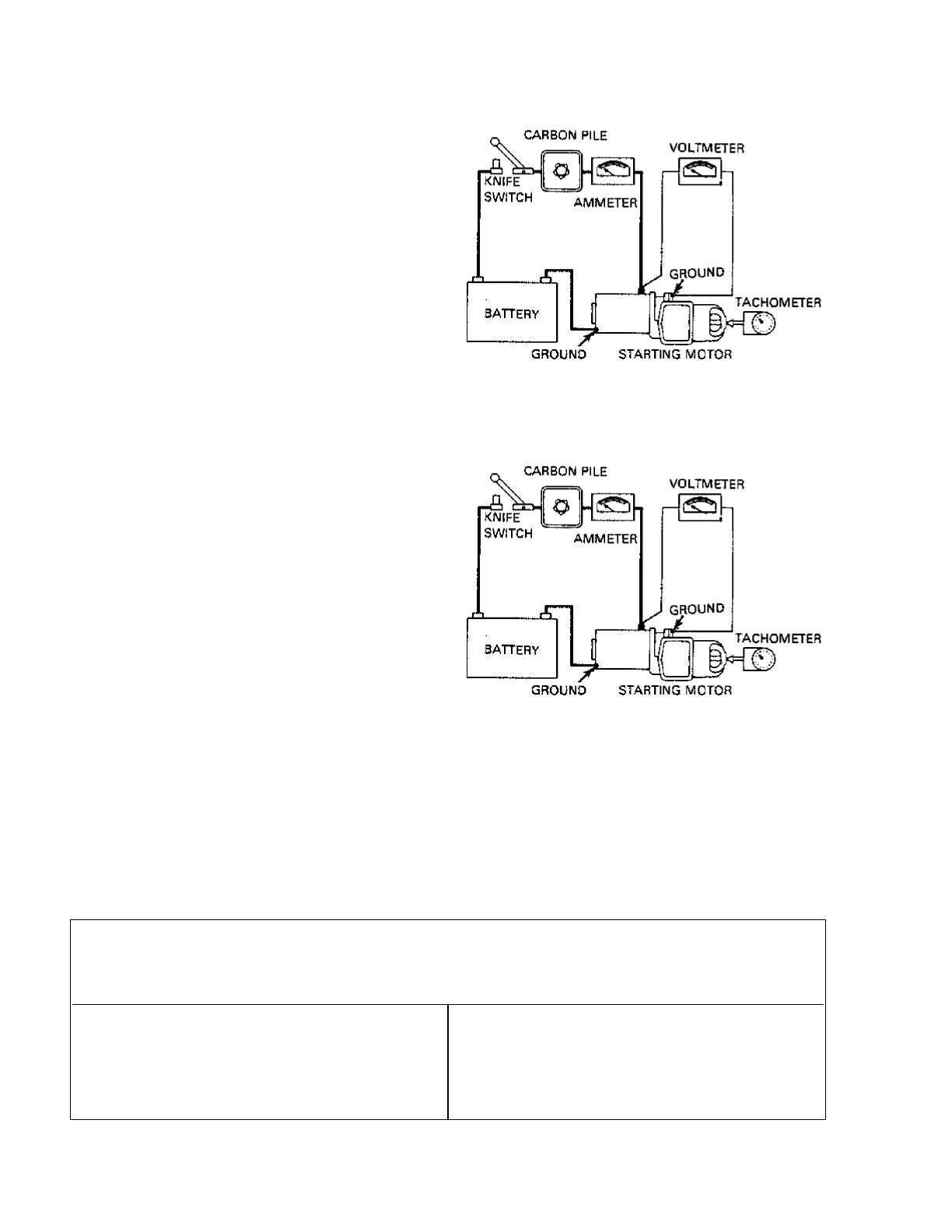

C. Bench Tests (See Figures 2 and 3.)

(1) No-Load Test

(a) Connect as shown in Figure 2.

(b) Current measured on voltmeter

should be within specifications

shown in Chart 2. If current is too

high, check the bearing alignment

and end play to make sure there is

no binding or interference. Two or

three sharp raps on the frame with

a rawhide hammer will often help

to align the bearings and free the

armature.

(c) If the starter passes the No-Load

Test, proceed to the Stall-Torque

Test, below.

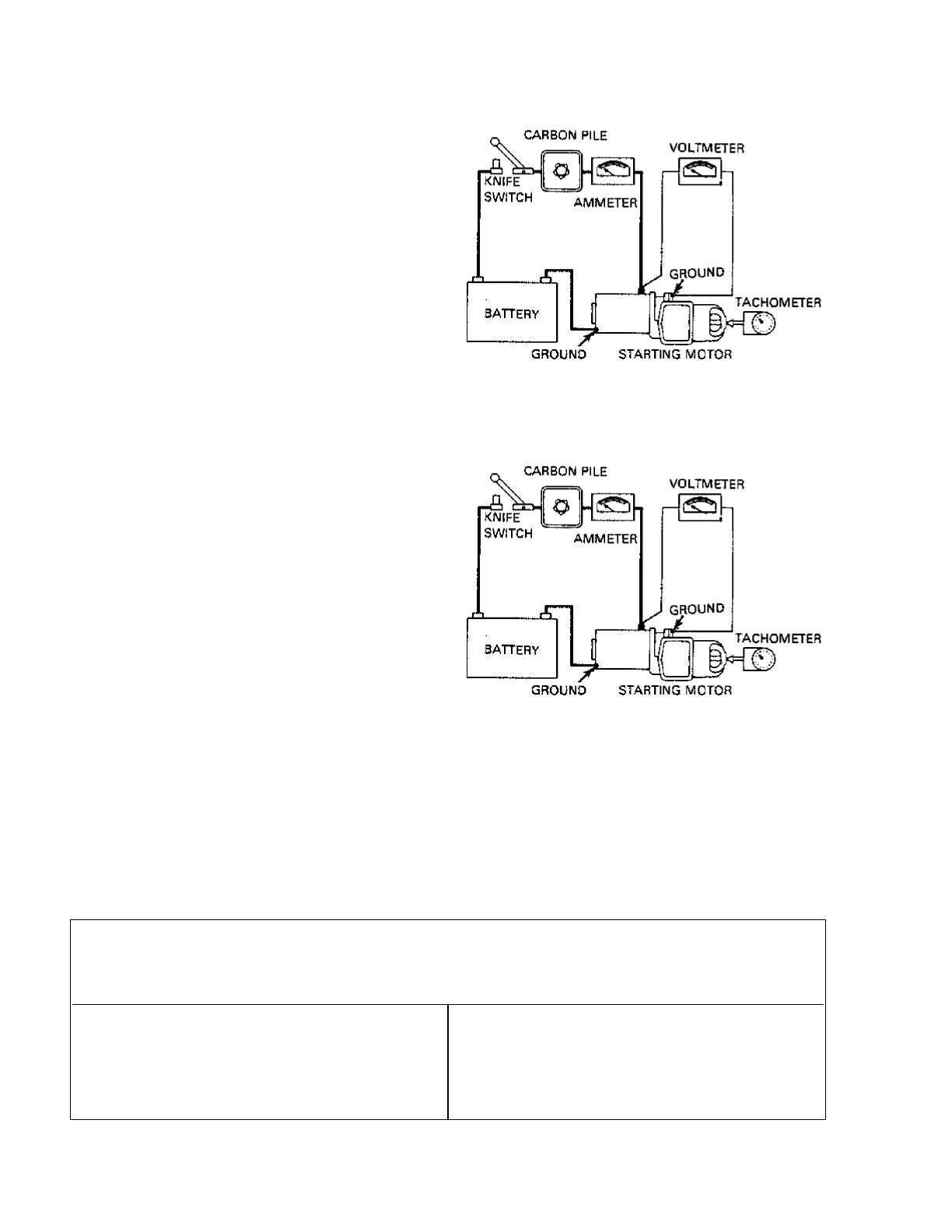

(2) Stall-Torque Test

To see if the starter is producing its

rated cranking power.

(a) Make test connections and set-up

as shown in Figure 3.

(b) Current measured on voltmeter

should be within specifications

shown in Chart 2.

(3) If torque and current are not within

specifications, overhaul or replace the

starter.

No-Load Test Set-up

Figure 2

Stall-Torque Test Set-up

Figure 3

Brush Tension (oz.)

Minimum 32

Maximum 48

No-Load Test (75 °F) Stall-Torque Test

Volt 23 Amps 270

Maximum Amps 40 Minimum Torque (Ft. Lbs.) 27

Minimum RPM 1000 Approximate Volts 18

CHART 2

SKY-TEC STARTER MODEL 149-12PM SERVICE TEST SPECIFICATIONS

Loading...

Loading...