THE NEW PIPER AIRCRAFT, INC.

PA-32-301FT / 301XTC

MAINTENANCE MANUAL

PAGE 1

Jun 1/03

5G21

91-10-00

CHARTS

1. T

orque

Requirements

CA

UTION: DO NOT OVERTORQUE FITTINGS.

NOTE: When installing flared fittings, verify that male threads are properly lubricated. Use torque

fittings values in Chart 1.

The torque values given in Chart 2 are derived from oil-free cadmium-plated threads and are

recommended for all airframe installation procedures where torquing is required, unless otherwise noted

in sections where other values are stipulated. Engine torque values are found in the latest revision of

Lycoming SSP-1776, and propeller torque values are found in 61-10-00. Chart 1 lists the torque values

for flared fittings of various sizes and material.

A. Calibrate the torque wrench periodically to assure accuracy, and recheck frequently.

B. Unless otherwise specified, torque all nuts to the applicable torque in Chart 2. If the nut

(or bolt) is listed but not its mating fastener, use the lower torque in Chart 2 for the listed nut (or

bolt).

NO

TE: If normal operation requires movement between any of the components being clamped

together, tighten the nut (or bolt) enough to insure intended operation of the assembly.

C. Bolt and nut threads should be clean and dry unless otherwise specified. If the threads are to be

lubricated, reduce the recommended nut torque given in Chart 2 (plus the friction drag torque) by

50%.

D. For thread sizes 10 through 7/16, add the friction drag torque (in Chart 2) for all self-locking

fasteners. For non-self locking fasteners, assume the friction drag torque to be zero.

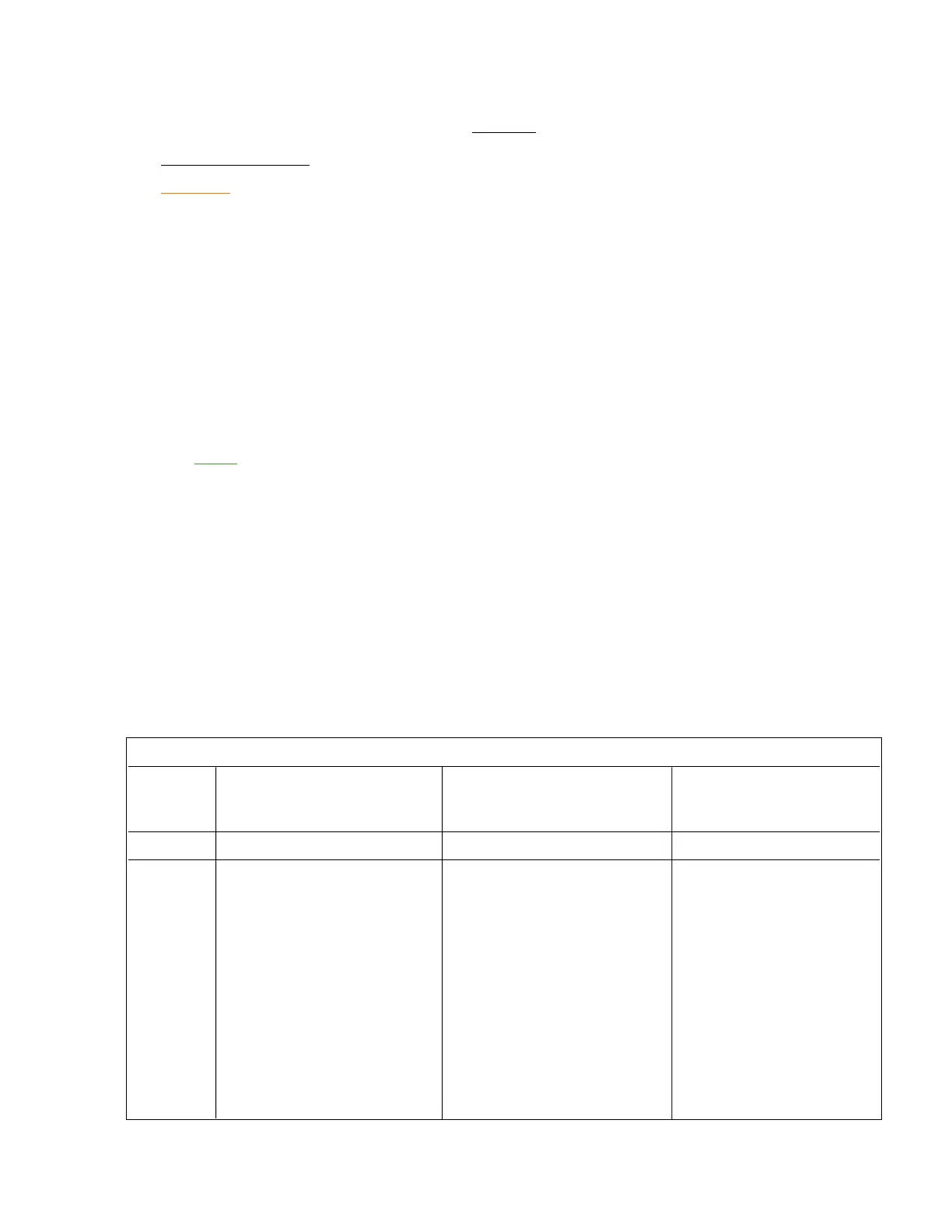

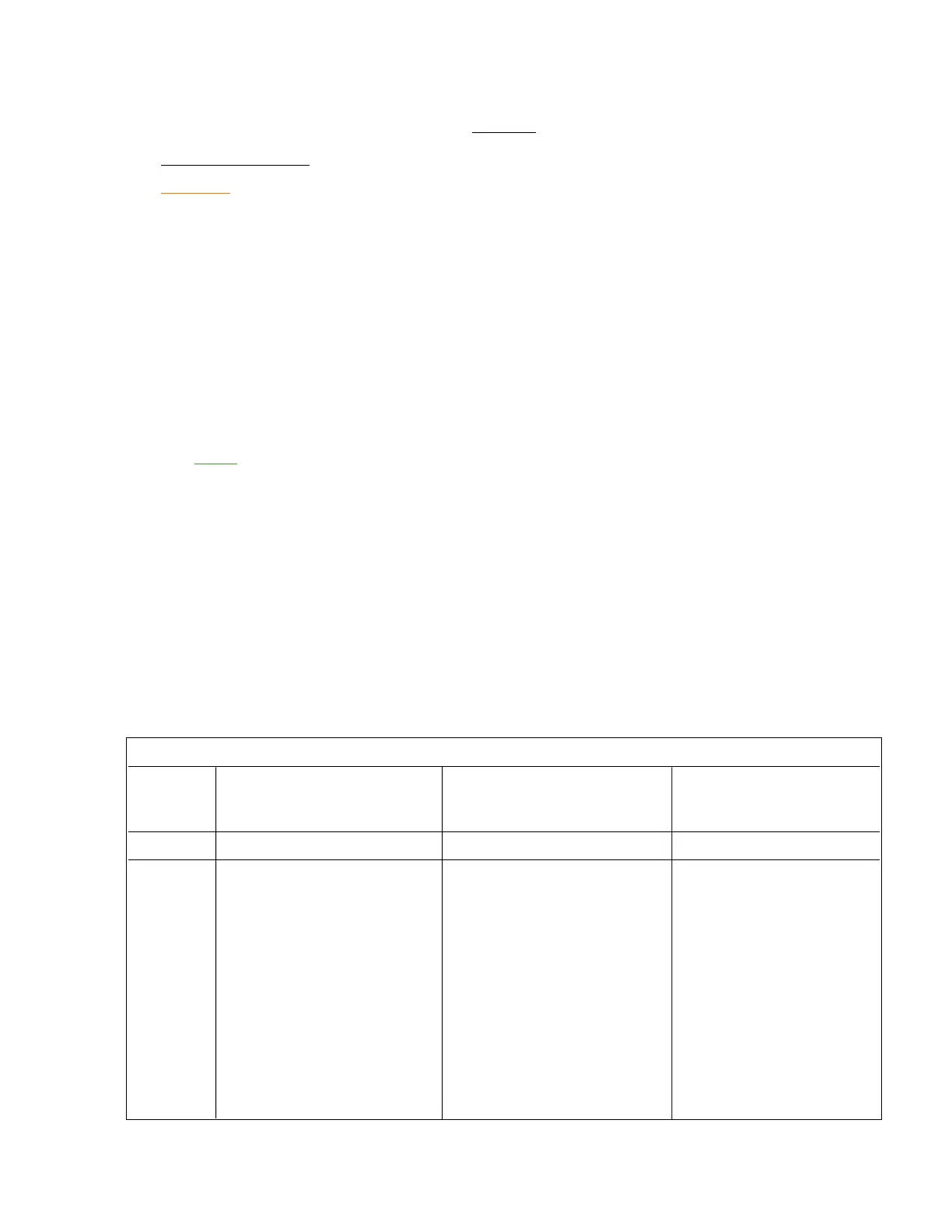

TORQUE — INCH-POUNDS

TUBING ALUMINUM - ALLOY STEEL TUBING HOSE END FITTING

OD TUBING FLARE - AND FLARE AND

INCHES 10061 OR AND 10078 AND 10061 HOSE ASSEMBLIES

MINIMUM MAXIMUM MINIMUM MAXIMUM MINIMUM MAXIMUM

1/8 ——— ——— ——— ——— ——— ———

3/16 ——— ——— 90 100 70 100

1/4 40 65 135 150 70 120

5/16 60 80 180 200 85 180

3/8 75 125 270 300 100 250

1/2 150 250 450 500 210 420

5/8 200 350 650 700 300 480

3/4 300 500 900 1000 500 850

1 500 700 1200 1400 500 1150

1-1/4 600 900 ——— ——— ——— ———

1-1/2 600 900 ——— ——— ——— ———

1-3/4 ——— ——— ——— ——— ——— ———

2 ——— ——— ——— ——— ——— ———

CHART 1

FLARE FITTING TORQUE VALUES

Loading...

Loading...