THE NEW PIPER AIRCRAFT, INC.

PA-32-301FT / 301XTC

MAINTENANCE MANUAL

PAGE 1

Jun 1/03

4J15

73-10-00

DISTRIBUTION

1. Fuel Injector Maintenance (Refer to Figures 2 and 3.)

In general, little attention is required between injector overhauls. However, it is recommended that the

following items be checked during periodic inspection of the engine:

A. Check tightness and lock of all nuts and screws which fasten the injector to the engine, torquing all

nuts to 135-150 inch-pounds.

B. Seat the pal type locknuts and finger tighten them against the plain nuts. After this has been done

tighten the locknuts an additional 1/3 to 1/2 turn.

C. Check all fuel lines for tightness and evidence of leakage. A slight fuel stain adjacent to the air

bleed nozzles is not cause for concern.

D. Check throttle and mixture control rod ends and levers for tightness and lock.

E. Remove and clean the injector inlet strainer at the first 25 hours of operation and each 50 hour

inspection thereafter. Check the screen for distortion or openings in the strainer. Replace for either

of these conditions. Clean screen assembly in solvent and dry with compressed air. Damaged

strainer O-rings should be replaced. To install the screen assembly, place the gasket on the screen

assembly and install the assembly in the throttle body and tighten to 35-40 inch-pounds torque.

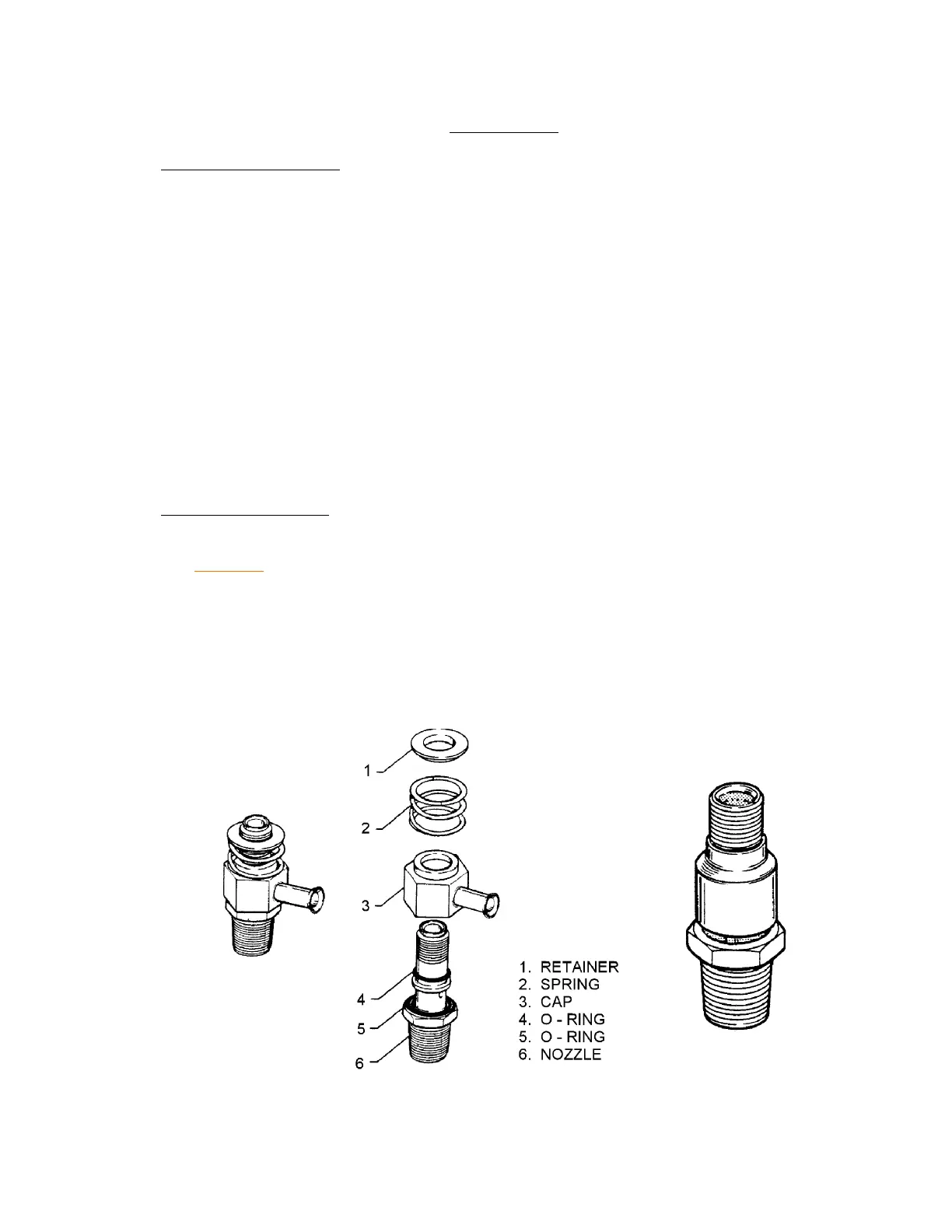

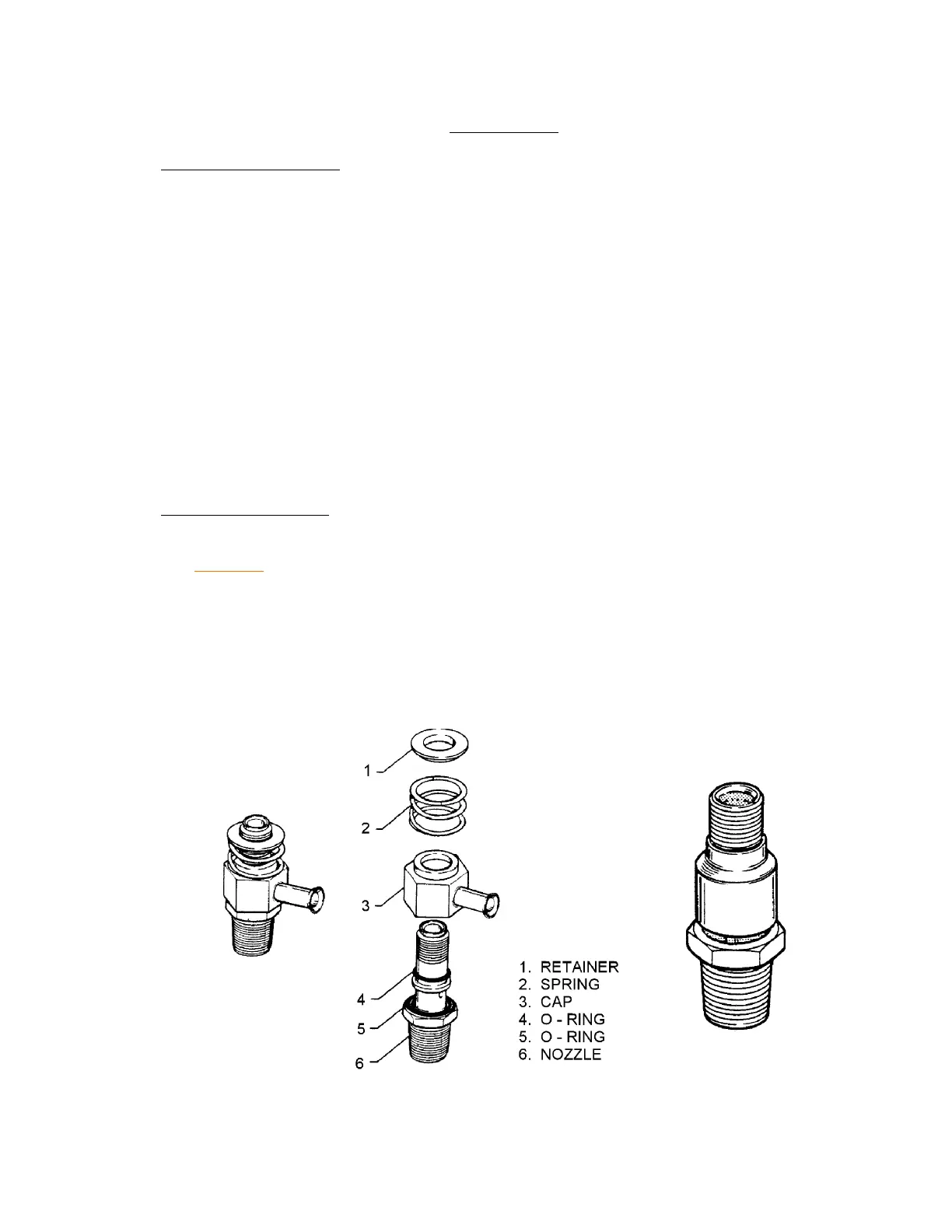

2. Fuel Nozzles (Air Bleed) (Refer to Figure 1.)

A. Removal

CAUTION: THE FUEL NOZZLES MUST BE CAREFULLY REMOVED, OR THE CYLINDERS MAY

BE DAMAGED.

(1) Remove the lower engine cowl.

(2) Disconnect the fuel line from the nozzle.

(3) Carefully remove the nozzle, using the correct size deep socket.

(4) Clean and inspect the nozzle as given in the next paragraph.

Fuel - Air Bleed Nozzles

Figure 1

Loading...

Loading...