THE NEW PIPER AIRCRAFT, INC.

PA-32-301FT / 301XTC

MAINTENANCE MANUAL

PAGE 5

Jun 1/03

5C11

74-10-00

B. Removal

CAUTION: ASCERTAIN THAT THE PRIMARY CIRCUIT OF THE ENGINE IS GROUNDED

BEFORE WORKING ON THE ENGINE.

Before removing the magnetos, make sure the magneto switches are OFF.

WARNING: THE MAGNETO IS NOT INTERNALLY GROUNDED, WHEN THE GROUND LEAD IS

DISCONNECTED THE MAGNETO IS HOT. REMOVING THE HARNESS ASSEMBLY

FIRST AND INSTALLING THEM LAST, MINIMIZES THE DANGER OF STARTING

THE ENGINE ACCIDENTALLY WHEN THE GROUND LEAD IS REMOVED FROM

THE MAGNETO.

(1) Turn the engine crankshaft in the normal direction of rotation until the No. 1 cylinder is in the

full-advance firing position.

(2) Remove the harness cap from the magneto. Before doing this, place an index mark on the

harness cap and distributor housing to ensure proper alignment upon reassembly.

(3) Disconnect the P-lead and pressurization tube from magneto.

(4) Remove the nuts, washers and clamps, and remove the magnetos from the engine.

(5) Cover the magneto accessory opening with suitable material to prevent internal engine

contamination.

C. 500 Hour Inspection and Cleaning

Each 500 hours, remove magneto per paragraph B, above, and disassemble magneto, as

necessary, per procedures in paragraph D, below. Inspect and clean magneto as follows:

(1) Inspect ball bearing assembly by rotating rotor shaft. Shaft should rotate freely without binding

or sticking, but should not appear loose. If not, replace bearings.

(2) Inspect rotor for damage or worn keyway. Check rotor surfaces for wear.

(a) Inspect oil seal location on shaft.

(b) Assemble bearings and rotor per paragraph E (1) & (2), below.

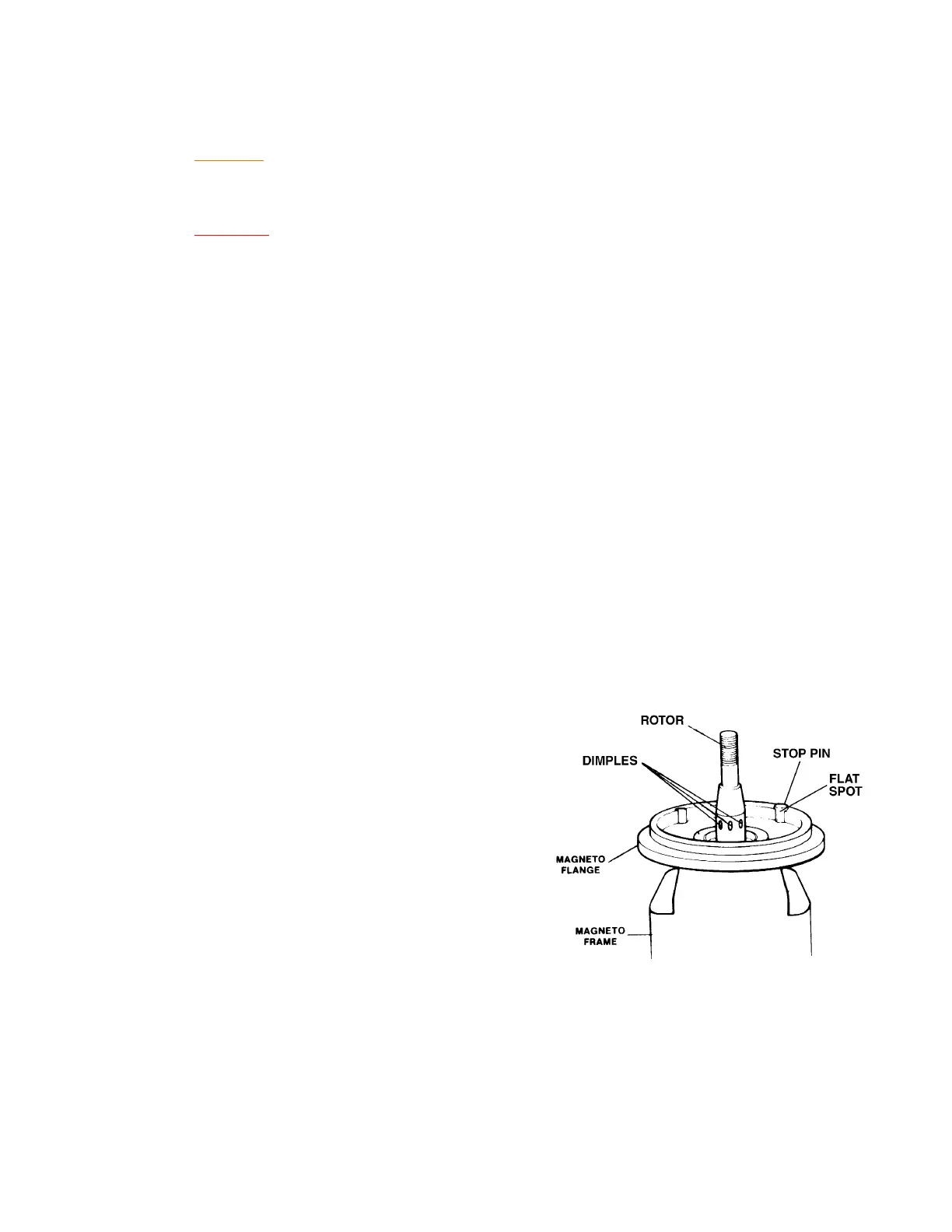

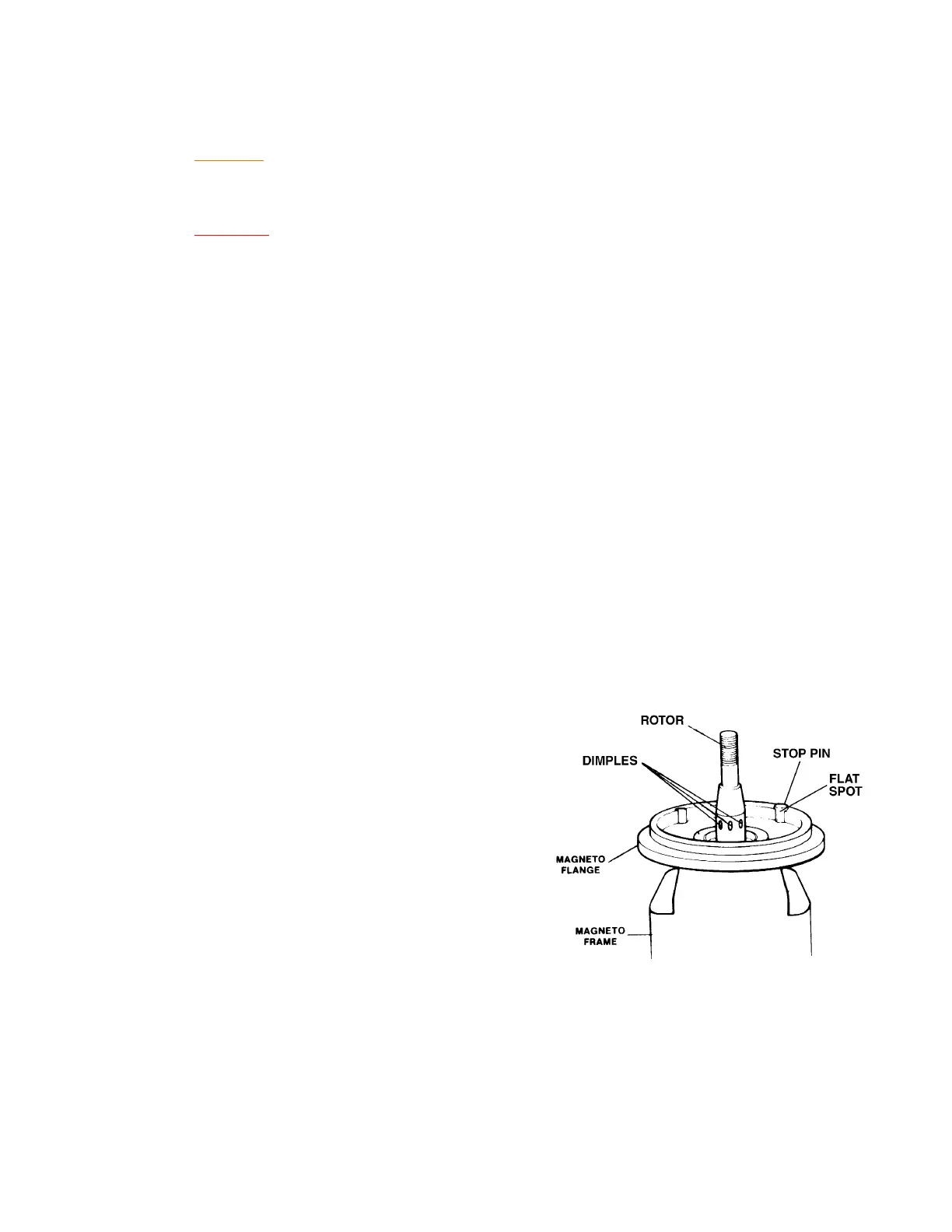

(c) In the left magnetos only (i.e. - impulse

coupled), inspect magneto rotor shaft

at impulse coupling (see Figure 2). If

the heel of the pawl has struck the

shaft and caused the shaft to dimple in

excess of .006 inch per side, the rotor

shaft must be replaced.

(3) In the left magnetos only (i.e. - impulse

coupled), clean and inspect the impulse

coupling:

(a) Clean to bare metal to ensure a

reliable inspection. Use a suitable

degreasing solvent to remove all oil or

sludge buildups.

(b) Inspect impulse coupling shell and hub

for cracks, rust or corrosion. Replace

impulse coupling, if found.

(c) Inspect hub shaft and keyway for

deformation or damage. Replace

impulse coupling, if found.

Rotor and Stop Pin

Figure 2

Loading...

Loading...