THE NEW PIPER AIRCRAFT, INC.

PA-32-301FT / 301XTC

MAINTENANCE MANUAL

PAGE 8

Jun 1/03

5C14

74-10-00

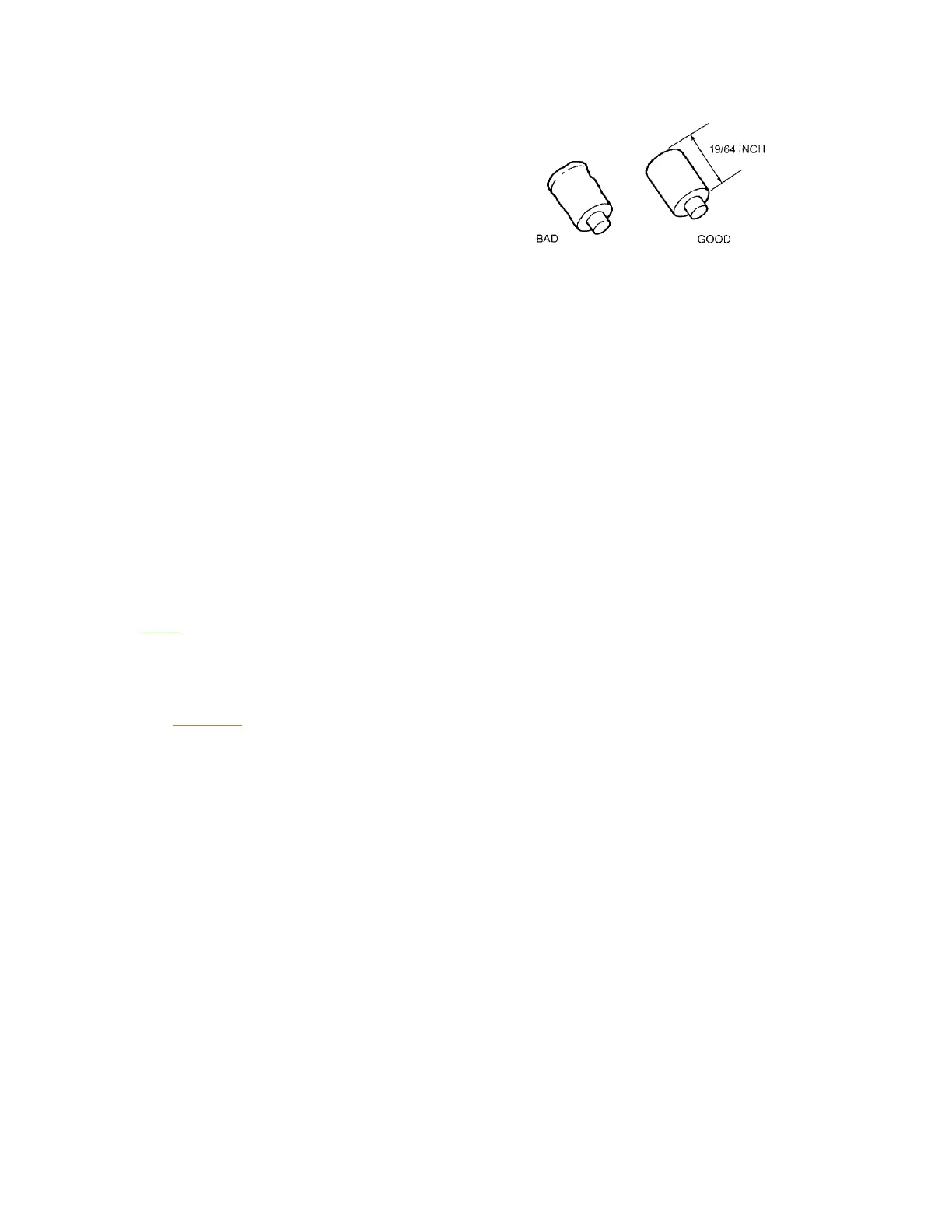

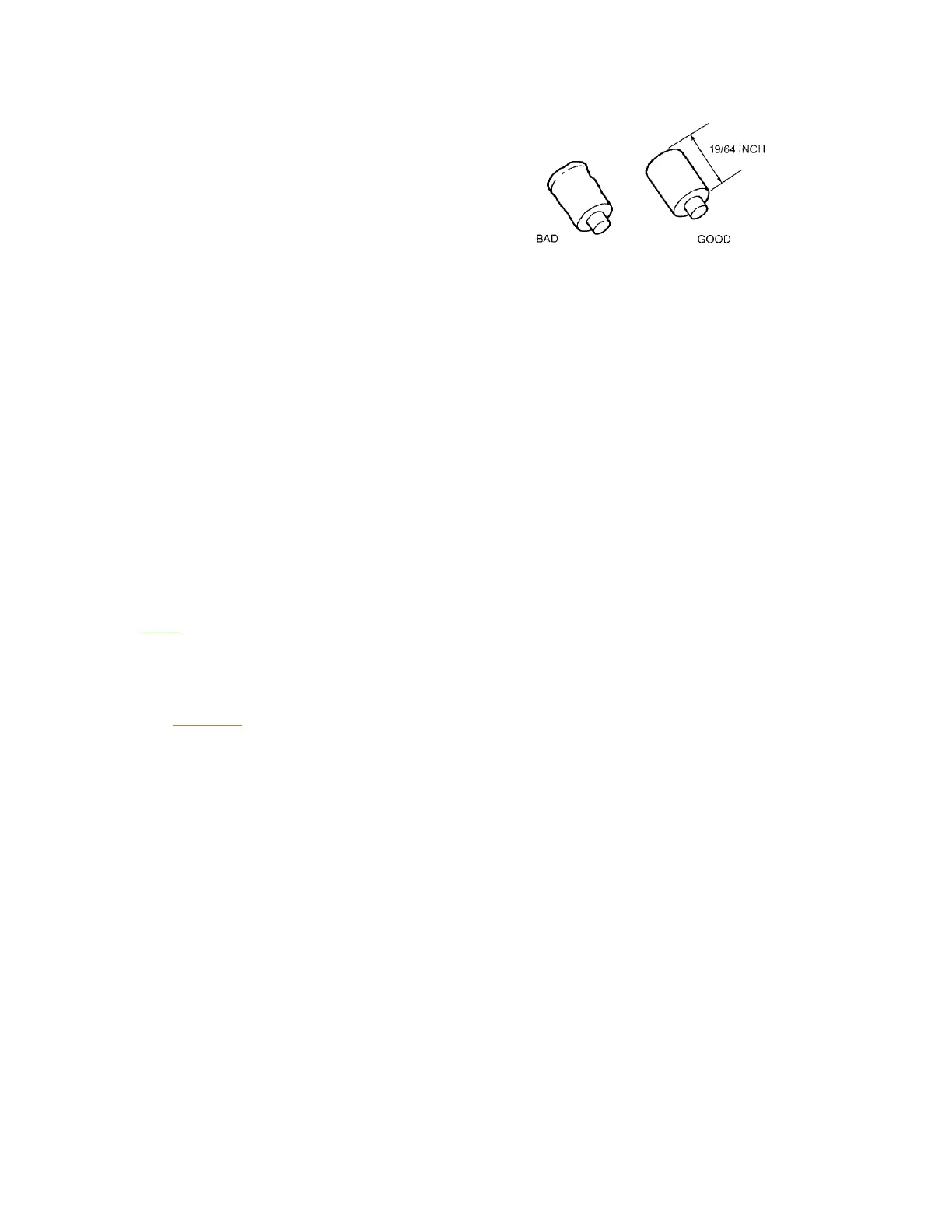

(9) Inspect the carbon brush. Overall

length must be greater than 19/64

(.297) inch and the outside diameter

must be uniform (see Figure 6).

Replace as required.

(10) Inspect the loading spring. Overall free

standing length should be greater than

19/32 (.594) inch. Springs that appear

worn, that have flat spots or are too

short must be replaced.

(11) In 6XT S/N’s 3255001 & up only (i.e. -

pressurized magnetos):

(a) Inspect turbo filter. Look for yellow or red color, condensation, water, or foreign matter in

the filter element. If the filter is contaminated: replace filter; inspect and repair

pressurization system; and remove and inspect magnetos.

(b) Inspect and clean inlet nozzle. Yellow or white particles or any oily film indicates moisture

contamination and possible lack of pressurization. Inspect and repair pressurization

system.

(c) Inspect and clean ofifice vent. Maximum orifice diameter is .025 inch.

(d) Inspect frame gasket for wear. Replace as required. Use only Slick replacement gaskets

as gasket contains a metal mesh to insure proper ground between magneto frame and

housing. Inspect screw gaskets for wear. Replace as required.

(e) Inspect harness cap O-ring for wear. Replace as required.

D. Disassembly (see Figures 7 and 8.)

NO

TE: Use of the Slick T-100 Assembly and Timing Kit (Figure 7) is strongly recommended. The

tools contained in this kit will greatly facilitate magneto disassembly/assembly and help

prevent damage to parts.

(1) Remove impulse coupling:

CA

UTION: THE SHELL OF THE IMPULSE COUPLING ASSEMBLY IS UNDER

CONSIDERABLE SPRING TENSION.

(a) Remove cotter pin, nut, washer and bushing; and drive gear, where applicable.

(b) Firmly holding the shell of the impulse coupling assembly, gently pull shell of impulse

coupling assembly out enough to clear the latching ears of the impulse hub assembly.

(c) Turn shell to release spring tension. Remove shell and attached impulse spring.

(d) Engage T-106 hub puller into grooves in the hub assembly. Tighten T-106 puller bolt to

remove impluse coupling hub assembly.

(2) Remove Woodruff key by prying key from rotor shaft using pliers.

(3) Remove distributor housing assembly

(a) Remove three long screws and single short screw from distributor housing.

(b) Separate distributor housing from magneto frame.

(c) Disconnect condenser lead from contact breaker assembly.

(4) Remove the distributor block assembly by removing two screws and remove distributor bearing

bar, distributor gear and distributor block from the housing.

(5) Remove condenser. When removing the condenser from the distributor housing, carefully

rotate the condenser wire counterclockwise in the same direction as the condenser to

eliminate twisting the condenser lead.

Carbon Brush Assembly

Figure 6

Loading...

Loading...