THE NEW PIPER AIRCRAFT, INC.

PA-32-301FT / 301XTC

MAINTENANCE MANUAL

PAGE 16

Jun 1/03

2D4

21-50-00

6 If there is a pressure drop, find leak(s) by applying a soap solution to all connections.

7 Tighten/re-tighten fittings as necessary to stop leak(s). If leaks are due to damaged

or worn components, proceed with refrigerant recovery/system discharge, perform

repairs or component replacement and repeat leak detection procedure.

(g) Using HFC-134a refrigerant:

1 Ensure that there is at least one pound of refrigerant in the charging cylinder.

2 Open the high pressure control valve and the refrigerant control valve on the

charging stand. Allow one pound of refrigerant to enter the system.

3 Close the high pressure control valve and the refrigerant control valve.

CAUTION

: IT IS RECOMMENDED THAT A THICK SOLUTION OF SOAP AND

WATER BE USED TO CHECK FOR LEAKS INSTEAD OF THE

PROPANE LEAK DETECTOR THAT IS PROVIDED WITH SOME

BRANDS OF CHARGING STANDS.

4

Locate leak(s) using an electronic leak detector designed to detect HFC134a

refrigerant. Or, use soap and water in a thick solution.

5 If no leaks are found, proceed to step (h).

6 Tighten/re-tighten fittings as necessary to stop leak(s). If leaks are due to damaged

or worn components, proceed with refrigerant recovery/system discharge, perform

repairs or component replacement and repeat leak detection procedure.

(h) Recover remaining refrigerant from system using the Robinair 34700 (or other approved)

charging station (see Discharging the System, above). Any quantity of oil recovered from

aircraft must be measured and an equal amount of new oil (i.e. - PAG with HFC134a)

must be added to system before recharging.

(i) Evacutate the system, see below.

(3) Evacuating the System

NOTE: Perform a Leak Detection check, above, before evacuting the system.

If the system has been operated in a discharged condition or anytime the system has been

open to atmospheric pressure, the receiver-dehydrator must be replaced and the system

evacuated to remove any trapped air and moisture which has entered it. A vacuum pump

capable of pulling 29 inches of mercury or better should be used. As the pressure in the air

conditioning system is lowered, the boiling temperature of the water (moisture) that may be

present is also lowered. This then forces any moisture, in the form of water vapor, out of the

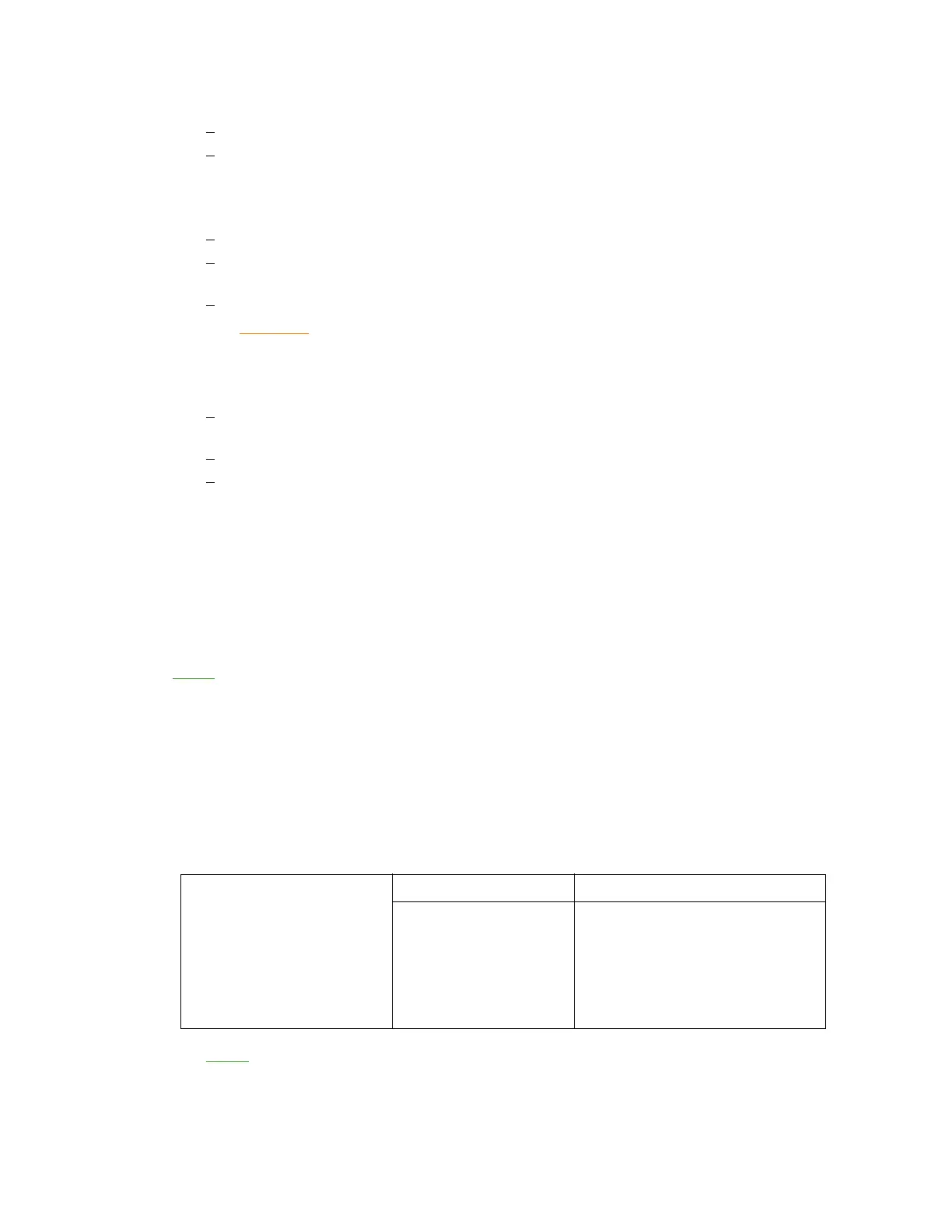

system. Chart 4 demonstrates the effectiveness of moisture removal under a given vacuum.

CHART 4

SYSTEM VACUUM

NO

TE: Compound gauge reading will be approximately one inch lower, numerically, for

each 1000 feet elevation above sea level.

COMPOUND GAUGE

READING IN INCHES

OF MERCURY VACUUM

System Vacuum

27.95

28.74

29.53

29.76

29.84

29.88

Temperature °F

101

84

52

29

15

1

Loading...

Loading...