THE NEW PIPER AIRCRAFT, INC.

PA-32-301FT / 301XTC

MAINTENANCE MANUAL

PAGE 17

Jun 1/03

5C23

74-10-00

F. Testing

Complete Magneto Reassembly, above. Verify that the T-118 Timing Pin has been removed.

(1) Mount the magneto on a suitable test stand in the same relative position as installed on the

engine.

(2) Install a Slick High-Temperature Ignition Harness on the magneto and connect each output

lead to a 5mm spark gap.

CAUTION: DO NOT OPERATE THE MAGNETO UNLESS THE IGNITION HARNESS IS

INSTALLED AND THE OUTPUT LEADS ARE CONNECTED TO THE 5MM GAP.

(3) Impulse Coupling

(a) Rotate the test stand drive pulley in the same direction of rotation stated on the magneto

data plate.

(b) The impulse coupling should engage the stop pin in the magneto frame below

approximately 200 RPM. If the impulse coupling pawls slip past the stop pin or engage

intermittently, the impulse coupling is not operating properly.

(4) Coming-in Speed

(a) Determine the lowest speed at which the magneto can be turned and still spark all 5mm

gaps without missing.

(b) The test gap must fire consistently at 200 RPM on non-impulse coupled magnetos and

350 RPM on impulse coupled magnetos.

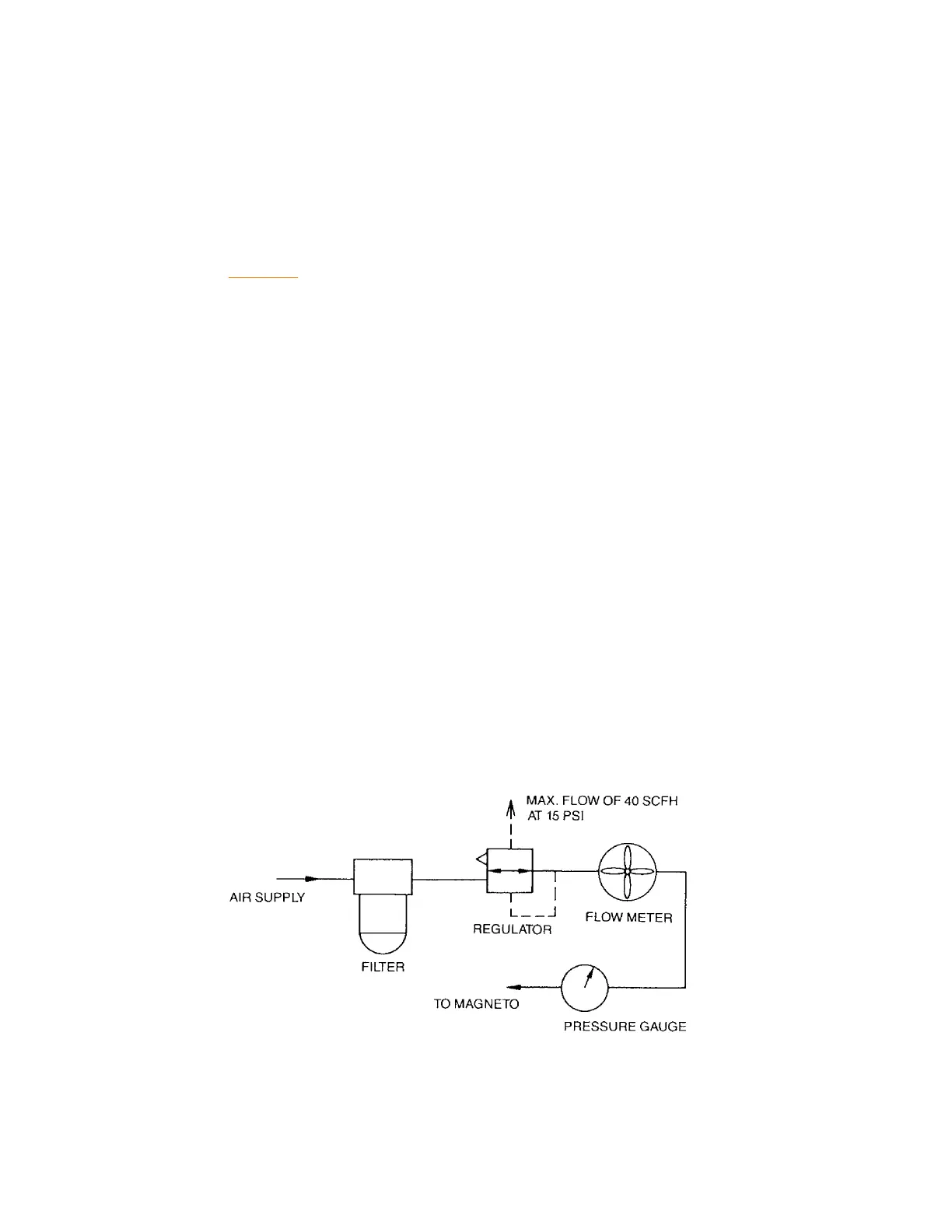

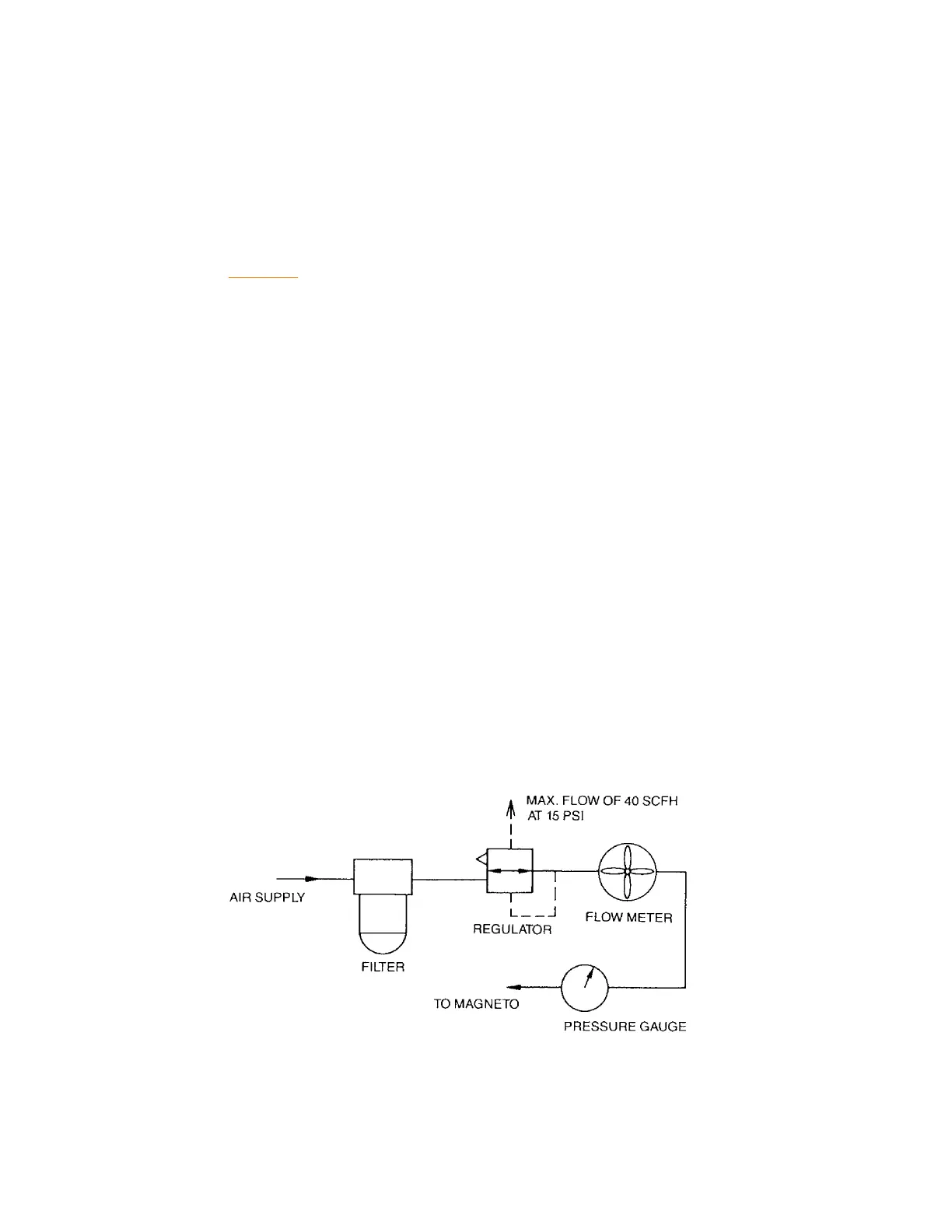

(5) Pressure Testing - In 6XT S/N’s 3255001 & up only (i.e. - pressurized magnetos)

After magneto reassembly, install a pressurized harness cap and apply 15 psi filtered air to the

inlet nozzle of the magneto (see Figure 15). Air flow at 15 psi is not to exceed 40 standard

cubic feet per hour (SCFH). If flow is excessive, reposition gaskets and retorque housing and

harness cap screws. Screws should be torqued to 21-25 in-lbs. for 6300 series magnetos.

Testing should be conducted with magneto at room temperature.

Pressurized Magneto Pressure Testing

Figure 15

Loading...

Loading...