THE NEW PIPER AIRCRAFT, INC.

PA-32-301FT / 301XTC

MAINTENANCE MANUAL

PAGE 7

Jun 1/03

4D11

51-00-00

2. Thermoplastic

Repairs

The following procedures will assist in making field repairs to items made of thermoplastic which are

used throughout the airplane. A list of material needed to perform these repairs is given in

Chart 1, along with suggested suppliers of the material. Common safety precautions should be observed

when handling some of the materials and tools used while making these repairs.

A. Surface Preparation:

(1) Surface dirt and paint if applied must be removed from item being repaired. Household

cleaners have proven most effective in removing surface dirt.

(2) Preliminary cleaning of damaged area with perchlorethylene or VM&P Naptha will

generally insure a good bond betweenn epoxy compounds and thermoplastic.

B. Surface Scratches, Abrasion or Ground-in-Dirt: (Refer to Figure 2.)

(1) Shallow scratches and abraded surfaces are usually repaired by following directions on

containers of conventional automotive buffing and rubbing compounds.

(2) If large dirt particles are embedded in thermoplastic parts, they can be removed with a hot air

gun capable of supplying heat in temperature range of 300°F to 400°F. Use care not to

overheat material. Hold nozzle of gun about 1/4 of an inch away from surface and apply heat

with a circular motion until area is sufficiently soft to remove dirt particles.

(3) Thermoplastic will return to its original shape upon cooling.

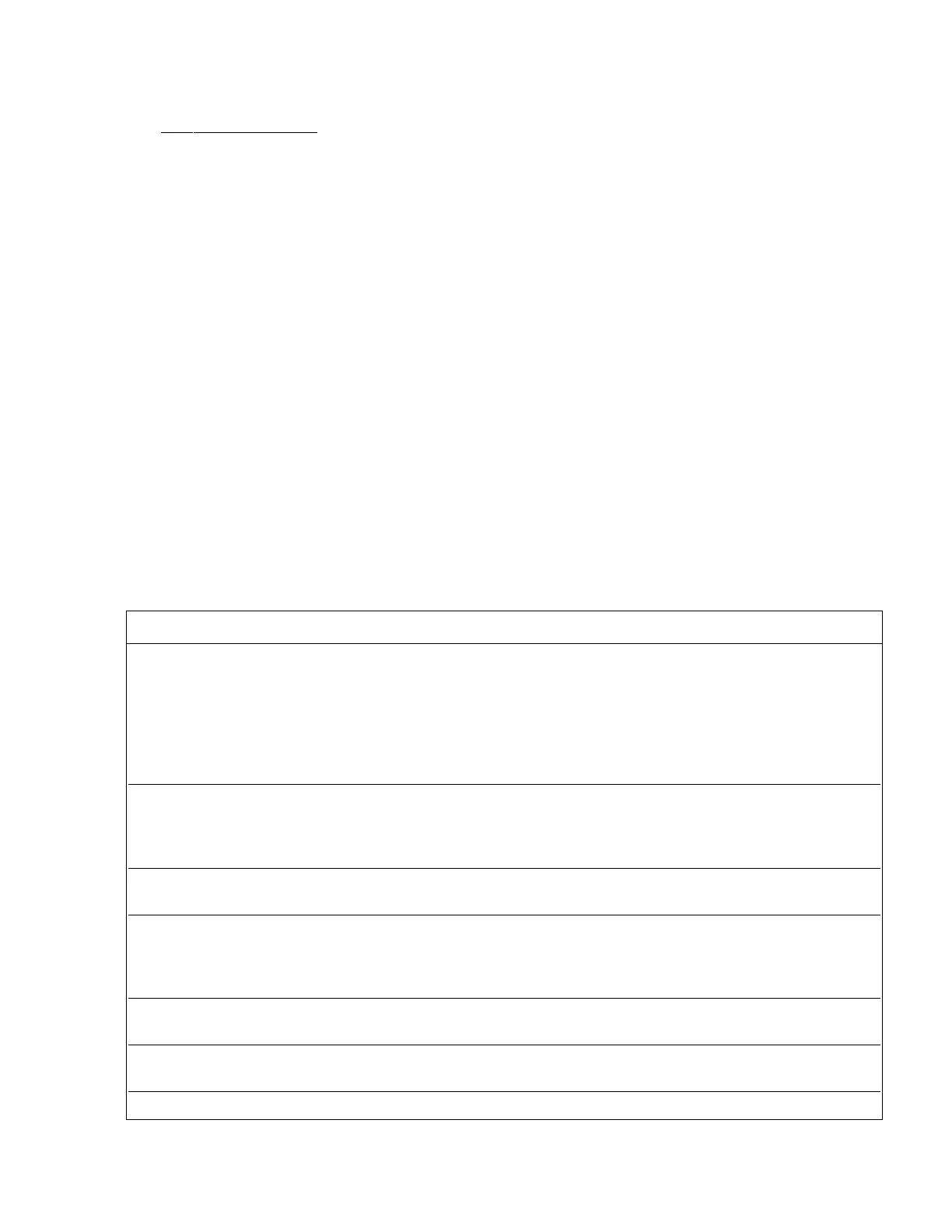

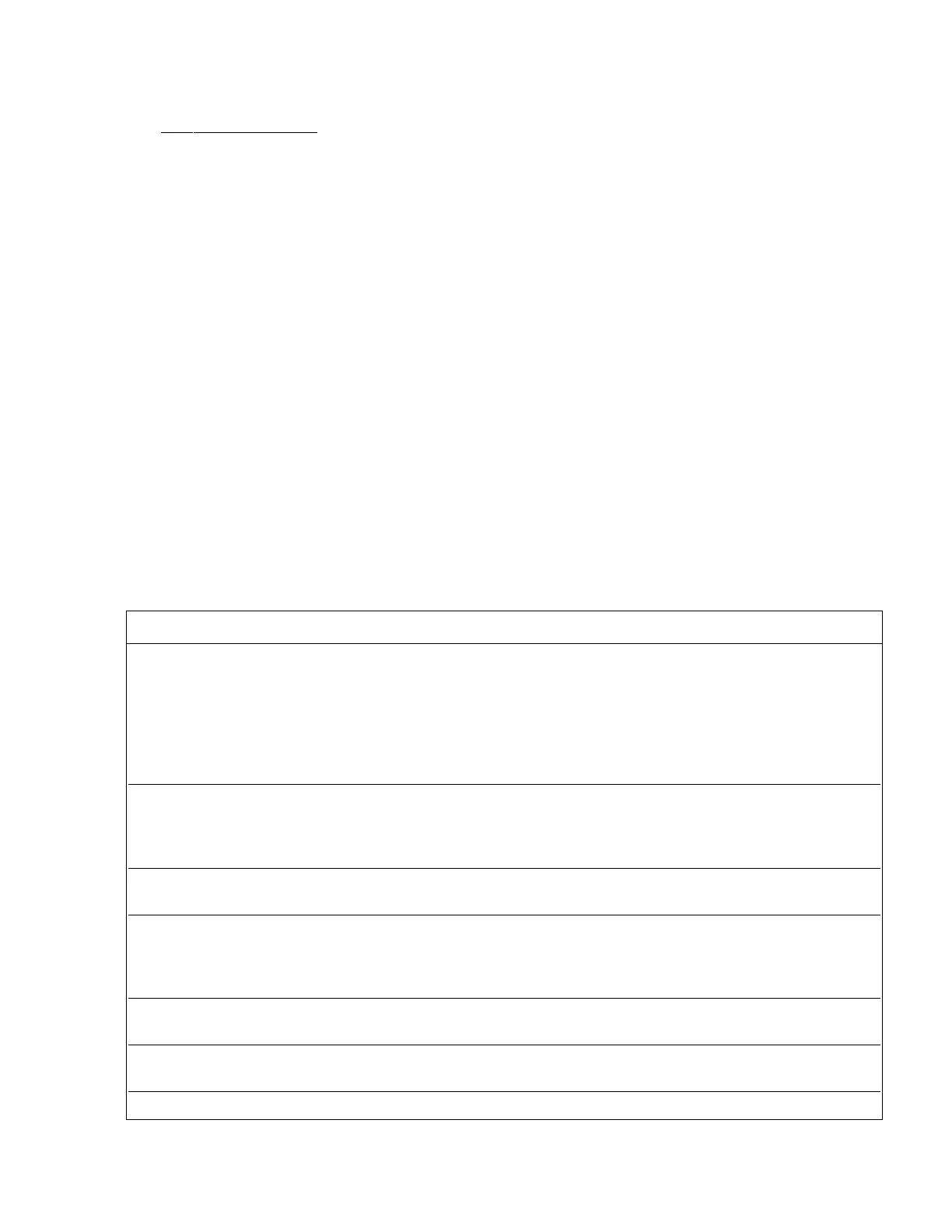

CHART 1

THERMOPLASTIC REPAIR LIST OF MATERIALS

Item Description Source

Buffing and Rubbing Automotive Type - DuPone DuPont Company

Compounds #7 Wilmington, DE 1998

Ram Chemical #69 x 1 Ram Chemicals

Gardena, CA 90248

Mirror Glaze #1 Mirror Bright Polish Co., Inc.

Irvin, CA 92713

Cleaners Fantastic Spray Local Suppliers

Perchlorethylene

VM&P Naptha (Lighter Fluid)

ABS-Solvent Cements Solarite 11 Series Solar Compounds Corp.

Linden, NJ 07036

Solvents Methylethyl Ketone Local Suppliers

Methylene Chloride

Acetone

Epoxy Patching Compound Solarite #400 Solar Compounds Corp.

Linden, NJ 07

Hot Melt Adhesives Stick From 1/2 in. dia. Sears Roebuck & Co., or

Polyamids and Hot Melt Gun 3 in. long most hardward stores

Hot Air Gun Temp. Range 300° to 400°F Local Suppliers

Loading...

Loading...