THE NEW PIPER AIRCRAFT, INC.

PA-32-301FT / 301XTC

MAINTENANCE MANUAL

PAGE 1

Jun 1/03

2G1

24-30-00

D.C.

GENERATION

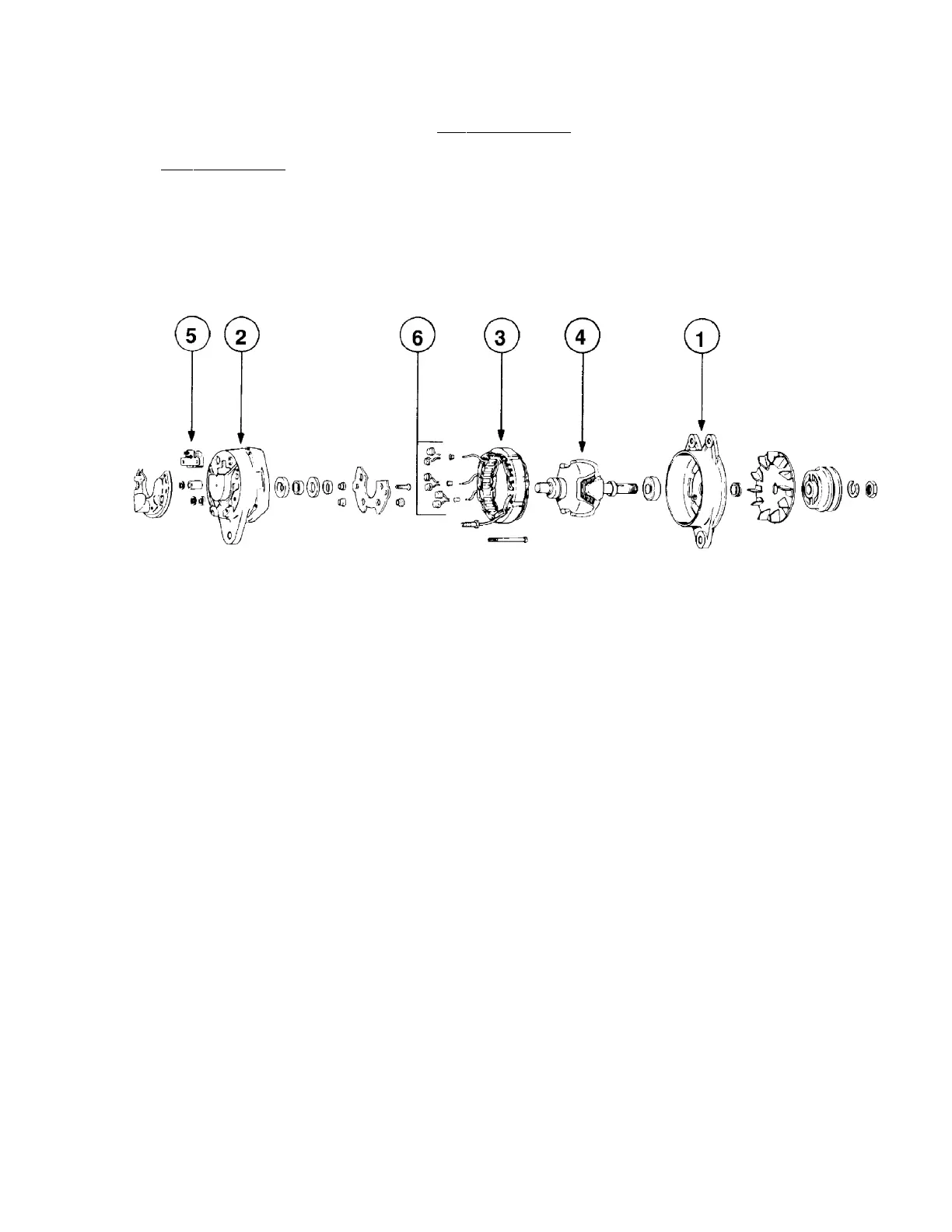

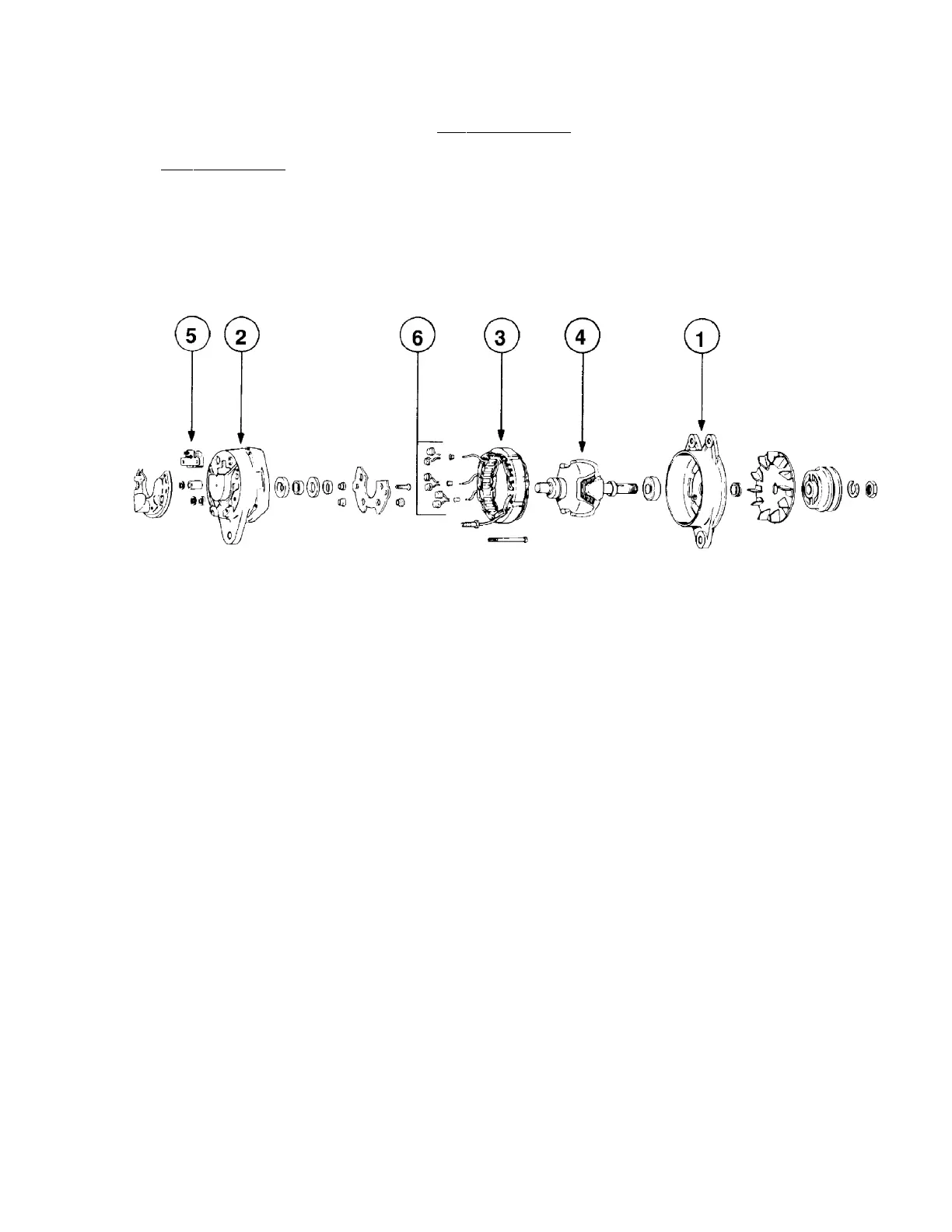

1. Alternator System (90 Amp Electrosystems. Inc.) (See Figure 1.)

A. Description

The principal components of the alternator are the front housing, fan and pulley, rear housing and

terminal identification, stator core and coil assembly, rotor core and coil, brushes and holder

assembly and rectifier assembly.

Exploded View of Electrosystems Alternator

Figure 1

(1) The front housing (1) is a die-cast aluminum part which meets design requirements for a

lightweight, non-magnetic material. This casting incorporates the bosses used to attach the

assembly to its mounting bracket. It also provides the supporting surface for the rotor shaft

front bearing and vendor identification data stamped into the front housing.

The fan and pulley are attached to the rotor shaft with a nut and lock-washer. The forward end

of the shaft is threaded to accept the nut.

(2) The rear housing (2) is also a die-cast aluminum part which supports the rotor shaft rear

bearing and provides mounting bosses for the rectifier assembly. The housing contains the

various electrical connections and openings for cooling airflow. (Refer to Figure 2 for Terminal

identification.)

(3) The stator core and coil assembly (3) consists of a number of steel stampings riveted together

to form the stator core which contains 36 equally spaced vertical slots to accommodate the

stator coil windings. (Refer to Figure 3.)

(4) The rotor core and coil assembly (4) consists of the rotor shaft, two slip rings, two rotor halves

and the coil assembly. The shaft is supported at each end by bearings. The front bearing (ball-

type) is a slip fit on the shaft and is retained in the front housing with a retainer. The rear

bearing (needle-type) is pressed into the rear housing. The slip rings, core and coil assembly

are press-fitted to the shaft with a rotor half enveloping each end of the coil.

The rotor core and coil assembly turns inside the stator core and coil assembly with a very

narrow air gap between the two assemblies, thus developing maximum magneto induction.

Loading...

Loading...