THE NEW PIPER AIRCRAFT, INC.

PA-32-301FT / 301XTC

MAINTENANCE MANUAL

PAGE 13

Jun 1/03

2D1

21-50-00

C. Servicing the System with a Charging Stand (Ref. PPS 50003-3, Rev. C)

CAUTION

: MINERAL OIL AND PAG ARE NOT COMPATIBLE. USE A SEPARATE MANIFOLD

TEST SET AND / OR TEST/CHARGING STAND AND RECOVERY SYSTEM FOR

EACH REFRIGERANT TYPE.

CAUTION: USE RECOVERY UNIT SPECIFICALLY DESIGNED FOR THE TYPE OF

REFRIGERANT USED IN THE AIRCRAFT SYSTEM. UNINTENDED AFFECTS MAY

OCCUR IF REFRIGERANTS ARE COMBINED.

(1) Discharging (Bleeding/Purging) the System (with a Robinair 34700 or similar charging

stand/recovery station) (see Figures 2 and 5) (Required only if system contains refrigerant.)

CAUTION: APPLIES TO ROBINAIR 34700 OR SIMILAR CHARGING/RECOVERY

STATION. SEE OPERATOR'S MANUAL OF STATION BEING USED FOR

DETAILED INSTRUCTIONS FOR DISCHARGING SYSTEM.

NO

TE: The term “Discharge,” as used throughout this section, in no sense implies or

suggests discharging refrigerant to atmosphere. In all cases when discharging, an

enviormentally approved refrigerant recovery station is to be used.

(a) Gain access to service valves by removing rear closeout panel in cabin.

(b) Remove protective caps from service valves.

(c) Connect high side (red) hose to air conditioner high side service valve. On systems

equipped with quick disconnect connections, open coupler valve.

(d) Connect low side (blue) hose to air conditioner low side service valve. On systems

equipped with quick disconnect connections, open coupler valve.

(e) Check the low side gauge (GAUGE 1) and high side gauge (GAUGE 2) to determine that

there is pressure in the system. If there is no pressure, there is no refrigerant in the

system to recover.

(f) Check that the oil drain valve is closed.

(g) Open both the low side and high side valves on control panel.

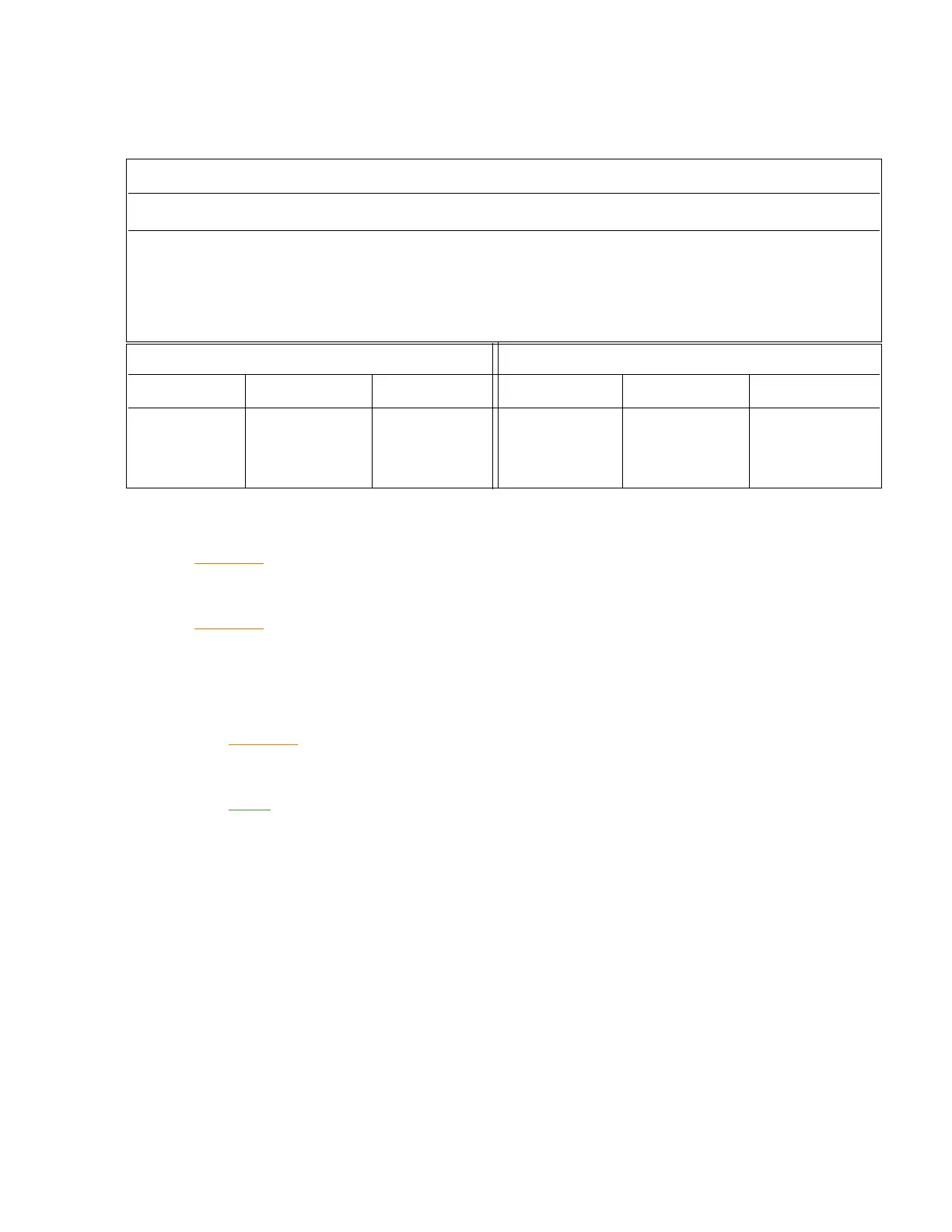

ALUMINUM TUBING

Metal Tube O.D. Thread and Fitting Size Ft./Lb.

1/4 7/16 5-7

3/8 5/8 11-13

1/2 3/4 15-20

5/8 7/8 21-27

3/4 1-1/16 28-33

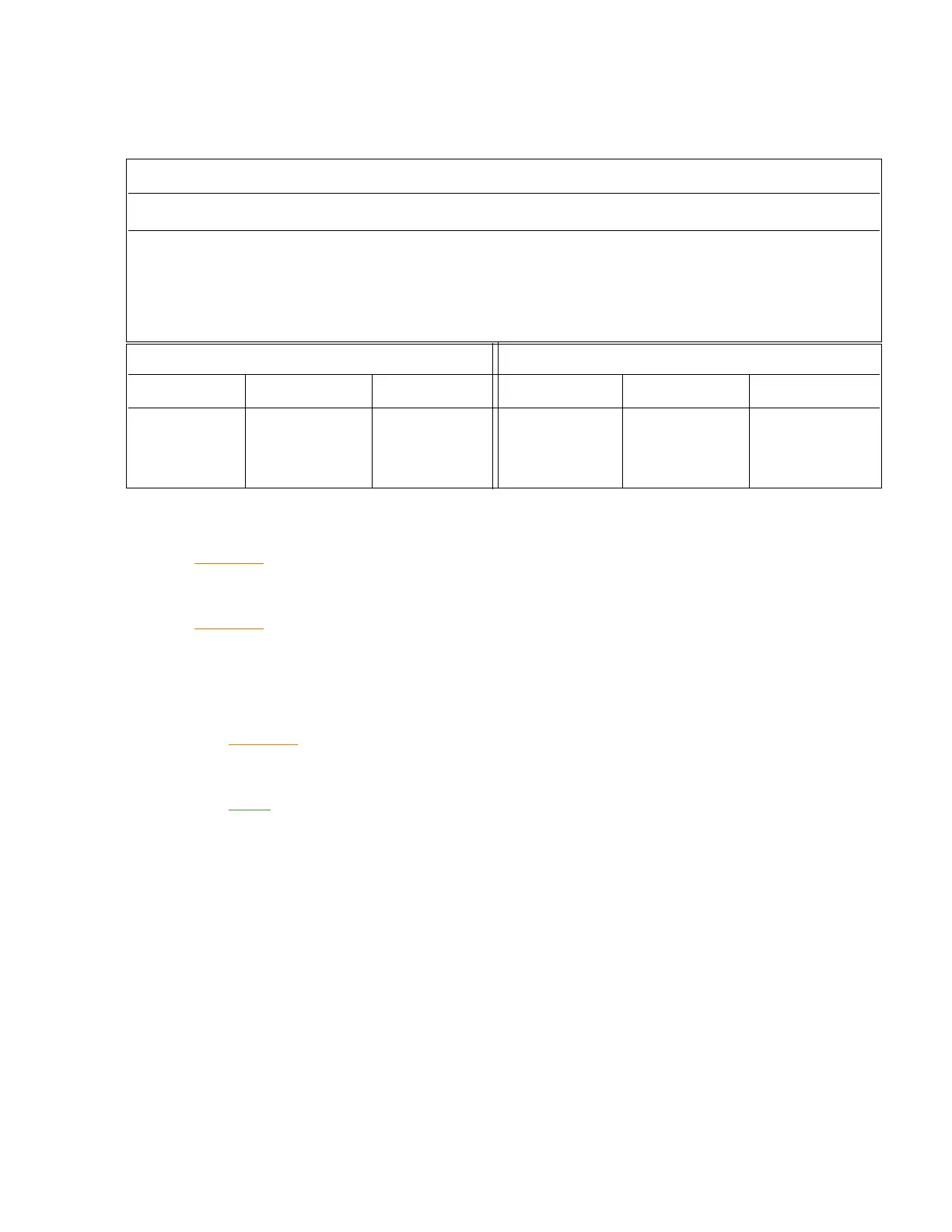

FLARE CONNECTIONS O-RING CONNECTIONS

Tube OD Thread size Ft./Lb. Tube OD Thread size Ft./Lb.

3/8 5/8 18-20 3/8 5/8 11-13

1/2 3/4 36-39 1/2 3/4 15-20

5/8 7/8 52-57 5/8 7/8 21-27

CHART 3

RECOMMENDED TORQUE SPECIFICATIONS

Loading...

Loading...