THE NEW PIPER AIRCRAFT, INC.

PA-32-301FT / 301XTC

MAINTENANCE MANUAL

PAGE 12

Jun 1/03

5C18

74-10-00

E. Assembly

NOTE: The following parts MUST BE REPLACED at engine overhaul (refer to Slick Service

Bulletin No. SB-2-80C). Condenser, drive end bearing, bearing cap assembly, impulse

coupling, coil, rotor gear, oil seal, contact point kit and distributor block and gear assembly.

Refer to Slick Part List for part numbers. At each 500 hour inspection replace parts that are

worn or damaged.

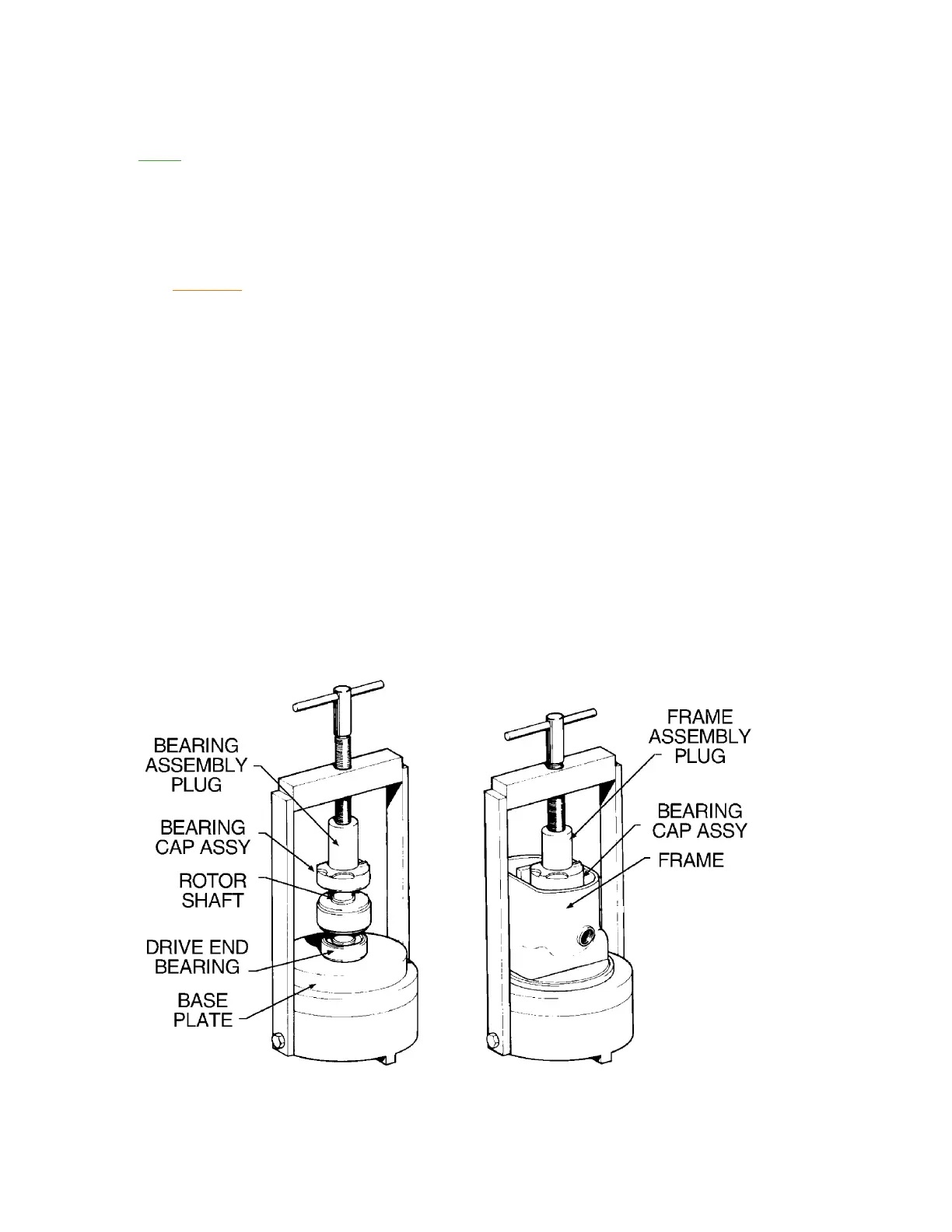

(1) Assemble new bearings onto shaft (see Figure 10.)

CAUTION

: DO NOT ALLOW ROTOR TO COME INTO CONTACT WITH METAL CHIPS OR

FILINGS. ROTOR IS MAGNETIZED.

(a) Insert the base plate (T-117) and adapter plate bushing (T-119) into T-125 assembly

fixture.

(b) Place one drive-end bearing and one bearing cap assembly onto the rotor shaft.

(c) Insert the rotor shaft into the adapter plate bushing (threaded end down).

(d) Place the bearing assembly plug (T-101) onto the exposed end of the rotor shaft.

(e) Turn T-handle screw to seat the bearings against the bearing shoulders on the rotor shaft.

(f) Remove the rotor shaft, adapter bushing, adapter plate and bearing assembly plug from

T-125 assembly fixture.

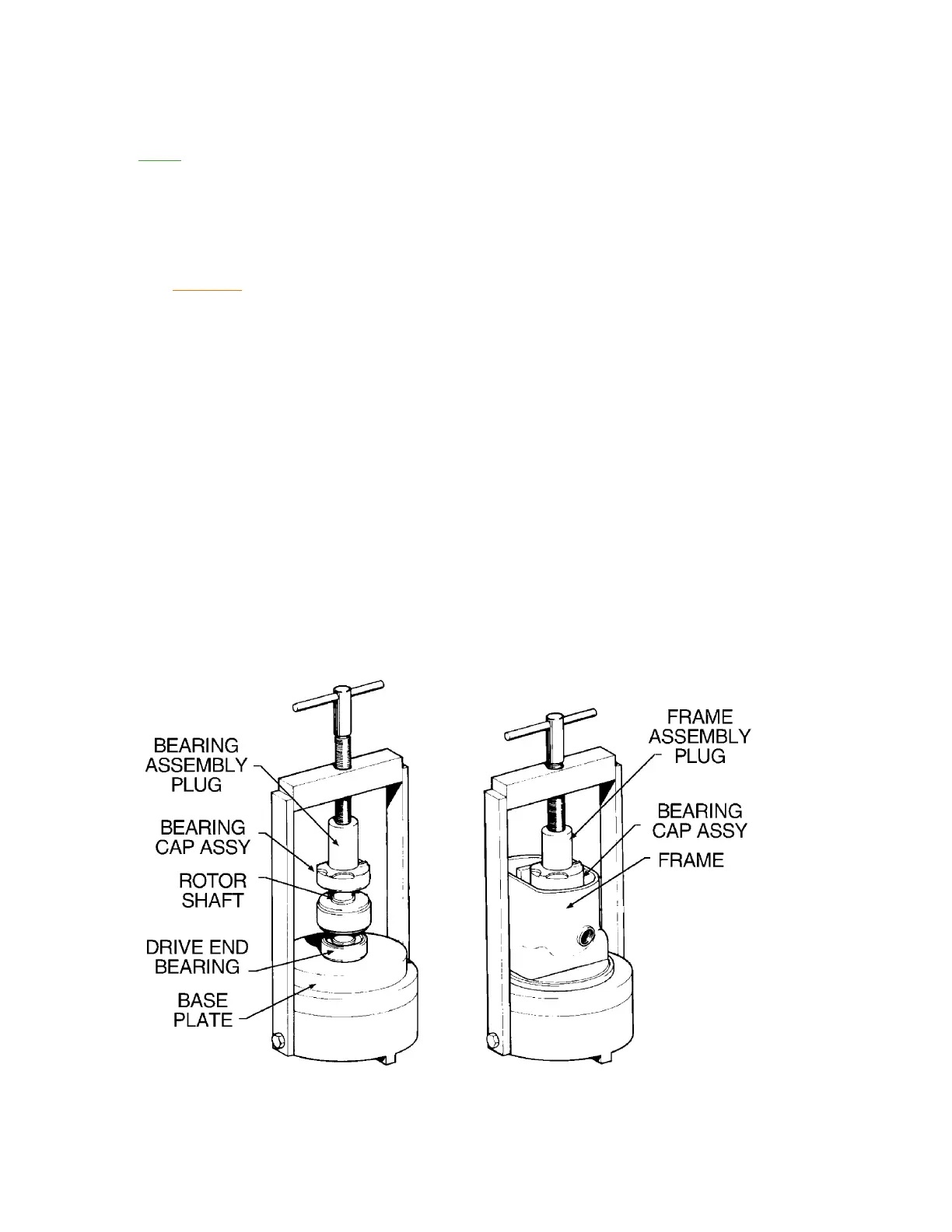

(2) Install rotor shaft assembly (see Figure 10.)

(a) Place magneto frame in T-125 assembly fixture (flange down).

(b) Position rotor shaft assembly in the magneto frame.

(c) Insert rotor and frame assembly plug (T-102) into the T-handle.

Installing Bearings

Figure 10

Loading...

Loading...