UM-PRORUNNER_Mk5-1.2-EN-US 117

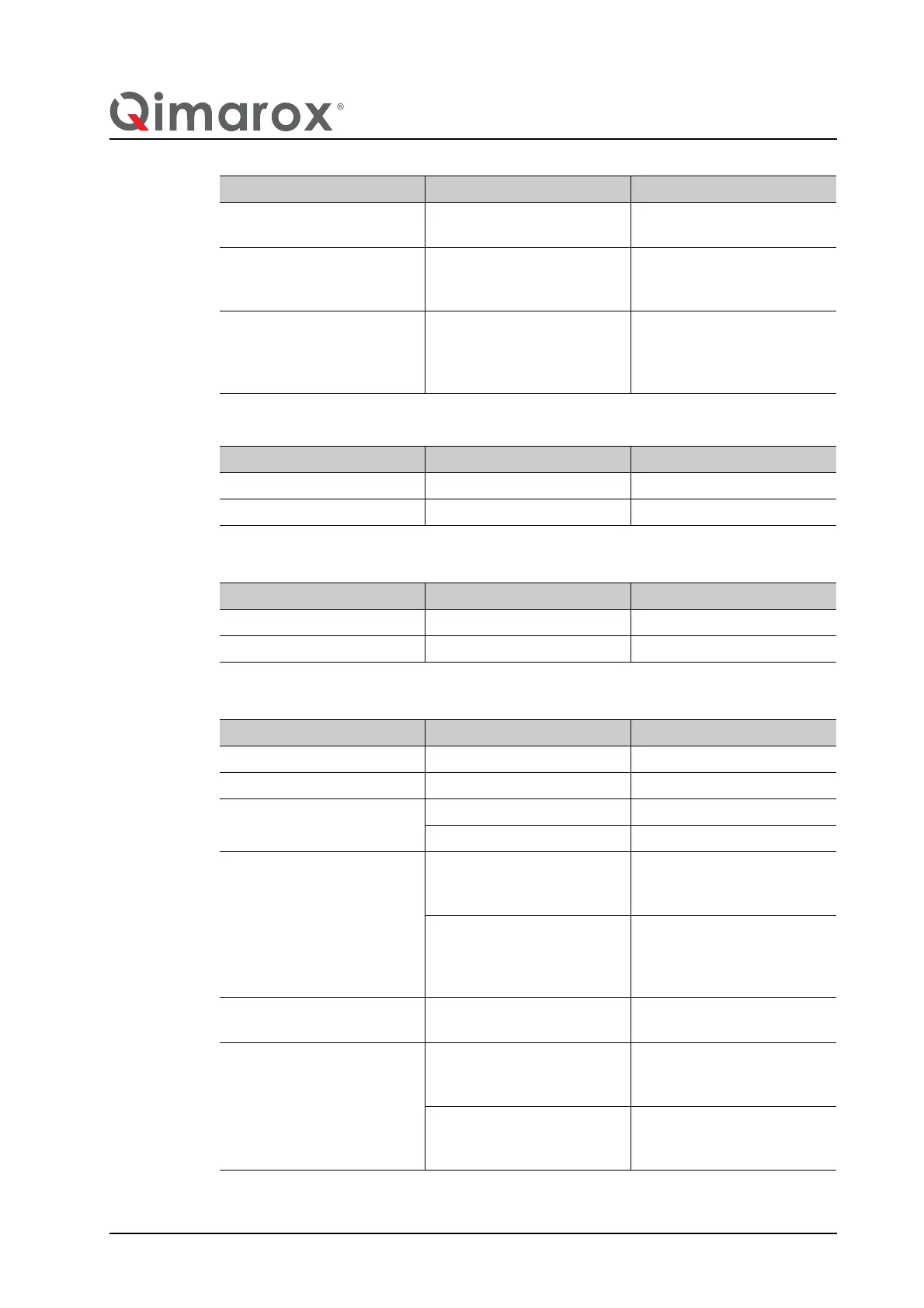

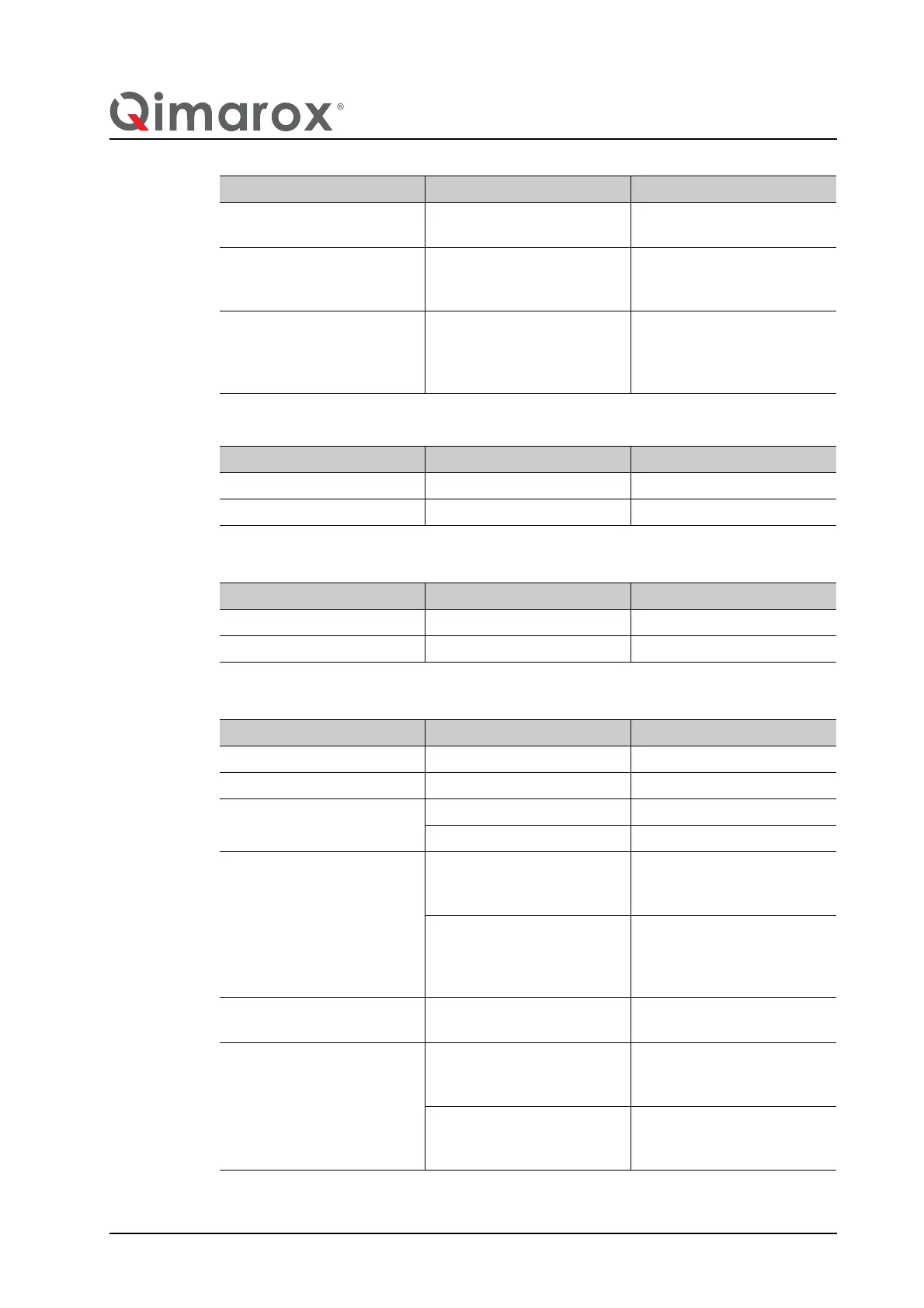

Troubleshooting

13.4 Gravity roller carrier

13.5 Gravity wheel carrier

13.6 Driven roller carrier

Use of energy (motor current)

too high and wear of drive belt.

The drive belt has been ten-

sioned too tightly.

Lower the tension of the belt.

The drive belt does not run in

line over the drive return

wheels.

Align the drive belt.

Use of energy (motor current)

too high and high temperature

of the bearing housing (some-

times accompanied by sound).

Ball bearing, ball bush or

returnroller is blocked.

Check the ball bearing, ball-

bush or return roller and

replace if necessary.

Problem Possible cause Solution

Roller is not running. Bearing is damaged. Replace roller.

Roller is making noise. Bearing is damaged. Replace roller.

Problem Possible cause Solution

Wheel is not running. Bearing is damaged. Replace wheel.

Wheel is making noise. Bearing is damaged. Replace wheel.

Problem Possible cause Solution

Roller is not running. Bearing is damaged. Replace roller.

Roller is making noise, Bearing is damaged. Replace roller.

RollerDrive does not run. No power supply. Check 24 VDC power supply.

Plug not connected properly. Check cable connection.

RollerDrive is rotating in the

wrong direction or at the wrong

speed.

Wrong DriveControl settings on

the speed and rotational direc-

tion Dip switches.

Change setting on DriveCon-

trol.

Wrong voltage at speed setting

pin (if the RollerDrive is not

operated with the recom-

mended InterrollDriveControl).

Check the voltage of the speed

setting pins on the motor plug.

Abnormal noise coming from

the RollerDrive.

Motor or gearbox is damaged. Replace the RollerDrive.

Interrupted RollerDrive opera-

tion.

Damaged motor cable. Check motor cable for dam-

age.If the motor cable is dam-

aged, replace the RollerDrive.

RollerDrive overloaded. See "Overload protection

device", in the Interroll docu-

mentation.

Problem Possible cause Solution

Loading...

Loading...