Maintenance vertical conveyor

62 UM-PRORUNNER_Mk5-1.2-EN-US

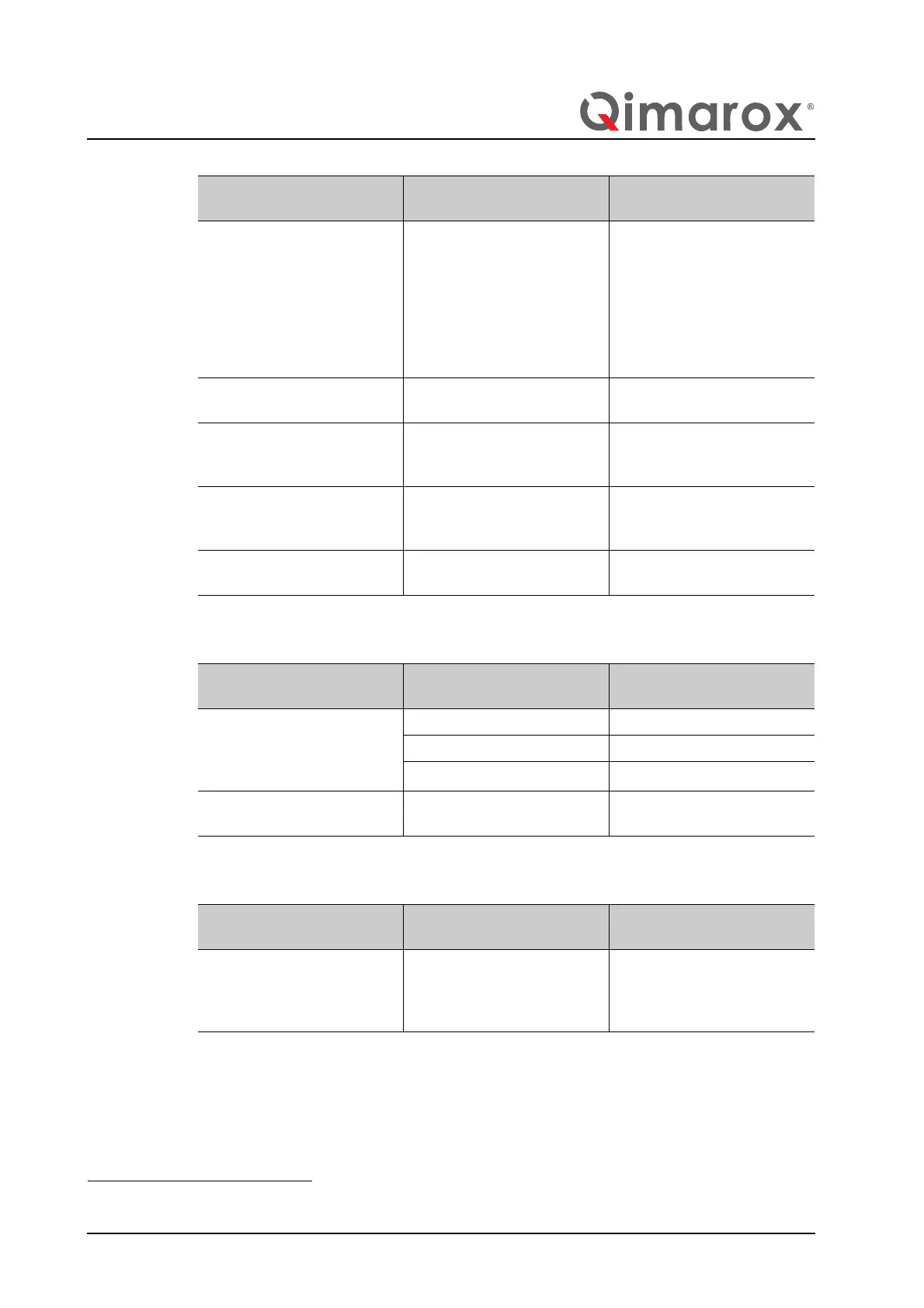

7.2.5 6-monthly maintenance

/i

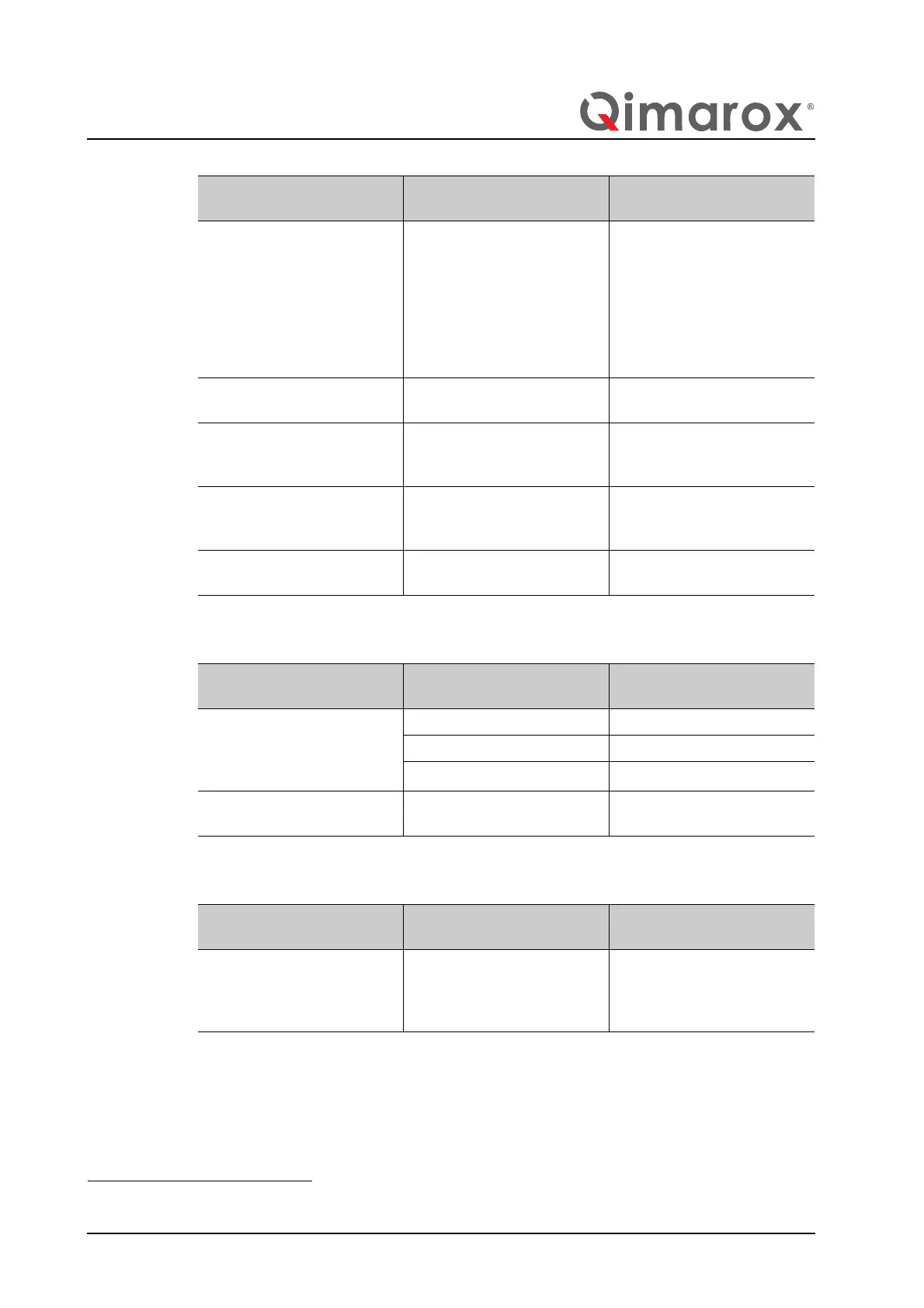

7.2.6 2-yearly maintenance

1

/i

Clamping bush for drive

sprocket wheel

Check if the socket screws are

fixed.

Tighten the socket screws to

the following torques:

• shaft diameter ≤ 40 mm:

17 Nm

• shaft diameter ≤ 65 mm:

41 Nm

• shaft diameter ≤ 95 mm:

83 Nm

Cabling Make sure that all cables are

securely fastened.

Connect the cables again if

necessary.

Adjusting rings of the guides Check if the adjusting rings are

fastened tightly and look for vis-

ible damage.

Replace the adjusting ring.

Refer to section 7.8.4.

Adjusting rings of the tension

wheel

Check if the adjusting rings are

fastened tightly and look for vis-

ible damage.

Replace the adjusting ring.

Refer to section 7.8.2.

Locking rings of the trolleys. Check the locking for presence

and for being fixed well.

Replace the locking ring (Star-

lock). Refer to section 7.8.2.

Item Task Action when required by the

check

Item Task Action when required by the

check

Motor reductor

Follow the instructions in the

manual of the manufacturer of

the motor reductor.

Check the oil level. Refill the oil.

Check the oil for contamination. Change the oil.

Check the air gap of the brake. Adjust the air gap.

All bolt connections Check all bolt connections. Tighten bolts using the correct

tool and torque.

1 Or after 10,000 running hours, whichever comes first.

Item Task Action when required by the

check

Motor reductor

Follow the instructions in the

manual of the manufacturer of

the motor reductor.

Change the oil.

Loading...

Loading...