UM-PRORUNNER_Mk5-1.2-EN-US 61

Maintenance vertical conveyor

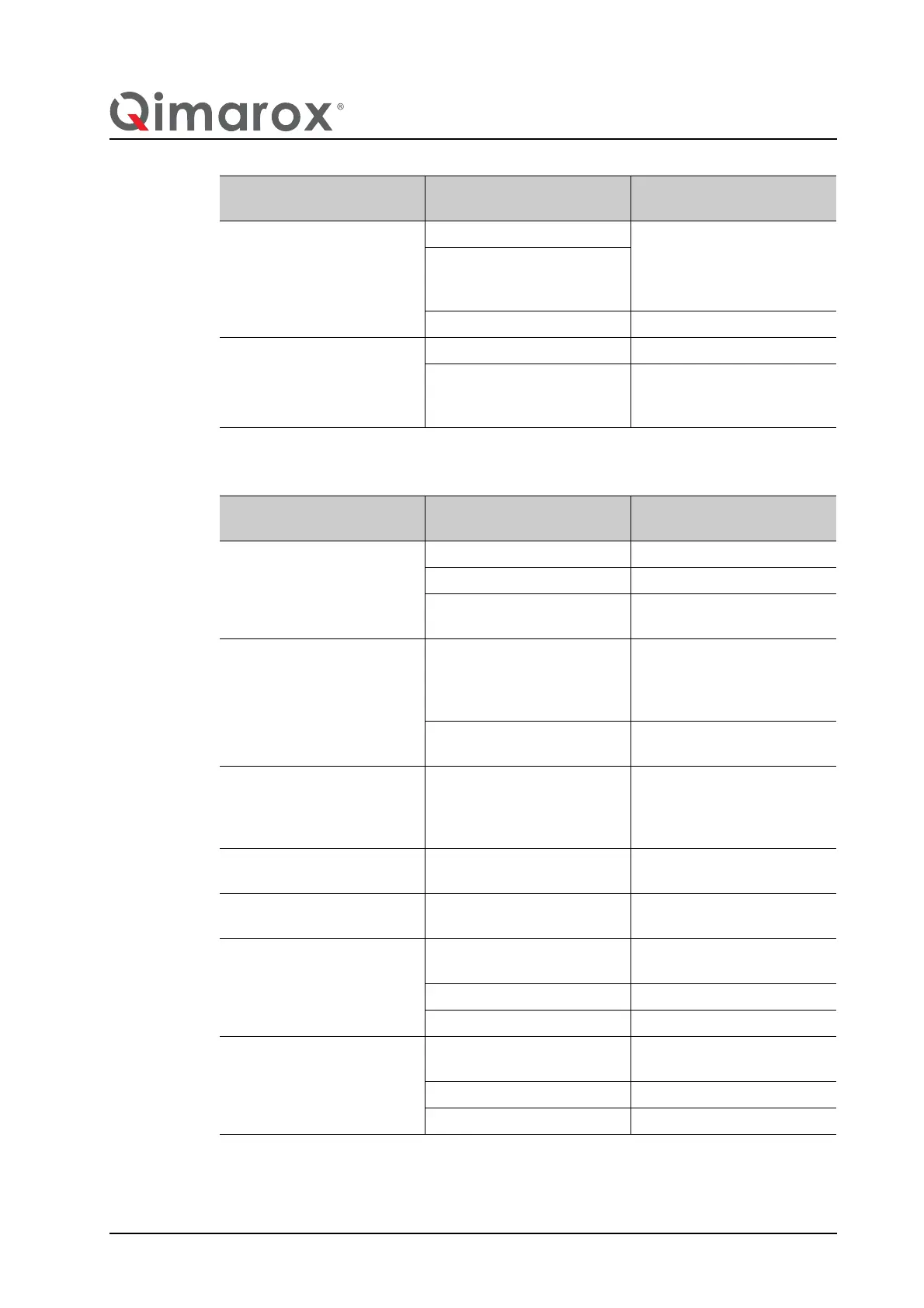

7.2.4 Monthly maintenance

/i

Product carriers Check for damage. Replace the product carrier.

Refer to section 7.8.3.

Check if the fastening bolt on

the carrying shaft is present

and has been correctly fixed.

Clean. Refer to section 7.3.

Curve plates Check for dirt. Clean. Refer to section 7.3.

Check for visible deformation of

the running surface.

Replace the curve plate. Refer

to section 7.8.6 (bottom side) or

section 7.8.7 (upper side).

Item Task Action when required by the

check

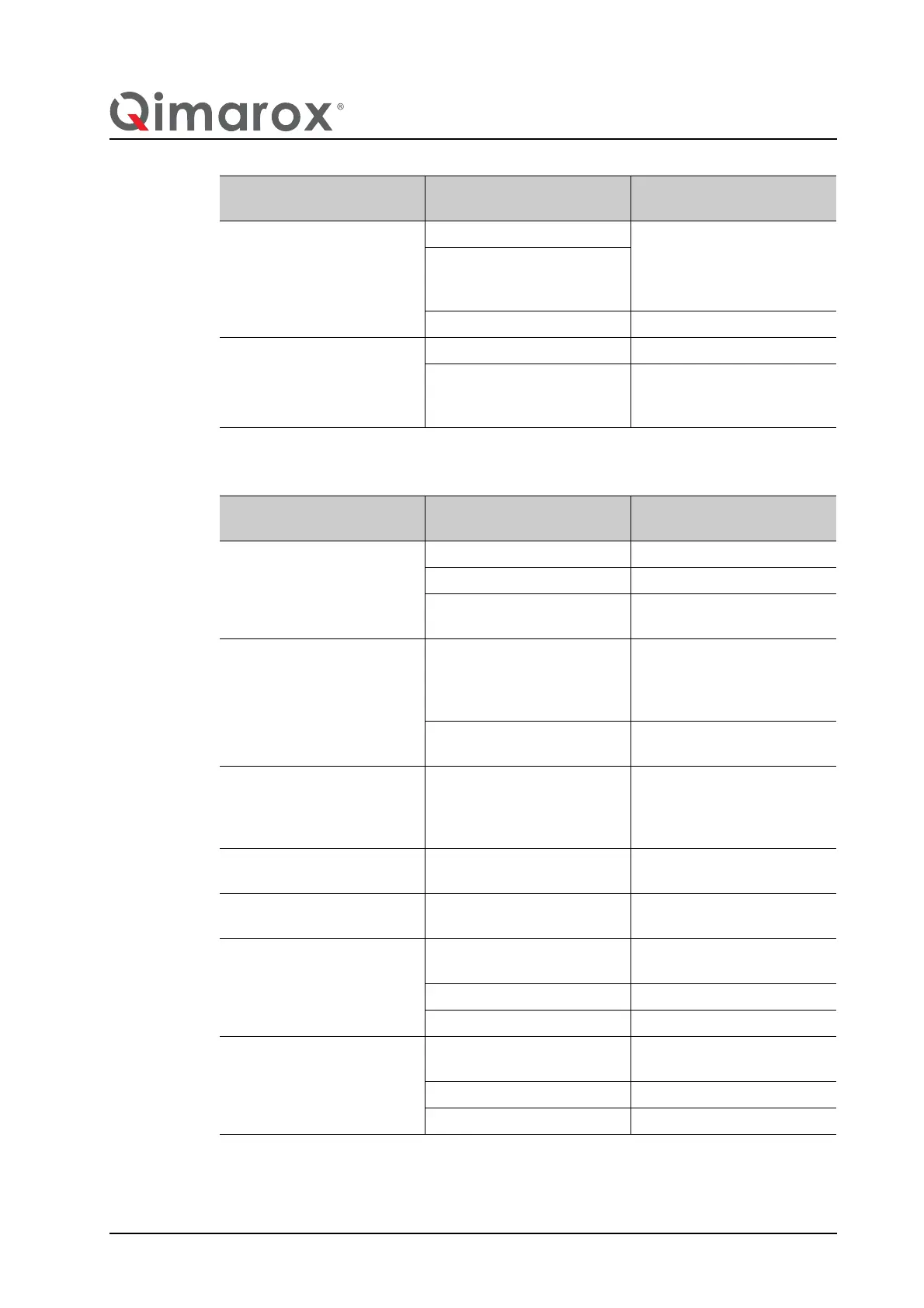

Item Task Action when required by the

check

Motor reductor

Follow the instructions in the

manual of the manufacturer of

the motor reductor.

Check the seals for leakage. Replace the seals.

Check for visible damage. Replace the damaged parts.

Check for running sounds. Replace the motor reductor.

Refer to section 7.8.12.

Chain Tighten the chain. Refer to sec-

tion 7.7.

Replace the chain if the training

device is at the end of the set-

ting range. Refer to section

7.8.8.

Lubricate the chain. Refer to

section 7.4.1.

Sprocket wheel and slide bear-

ings

Check for slack. Refer to sec-

tion 7.5.

Replace the slide bearings of

the tensioning wheel when

there is too much slack. Refer

to section 7.8.9.

Bearings of the wheels of the

trolley

Check for slack. Refer to sec-

tion 7.8.2.

Replace the wheels. Refer to

section 7.8.2.

Bearings of the wheels of the

guide

Check for slack. Refer to sec-

tion 7.6.

Replace the wheels. Refer to

section 7.8.5.

Photocells Check for visible damage. Replace the photocell if neces-

sary.

Check for loose parts. Fasten loose parts.

Clean. Refer to section 7.3.

Inductive sensors Check for visible damage. Replace the sensor if neces-

sary.

Check for loose parts. Fasten loose parts.

Clean. Refer to section 7.3.

Loading...

Loading...