UM-PRORUNNER_Mk5-1.2-EN-US 95

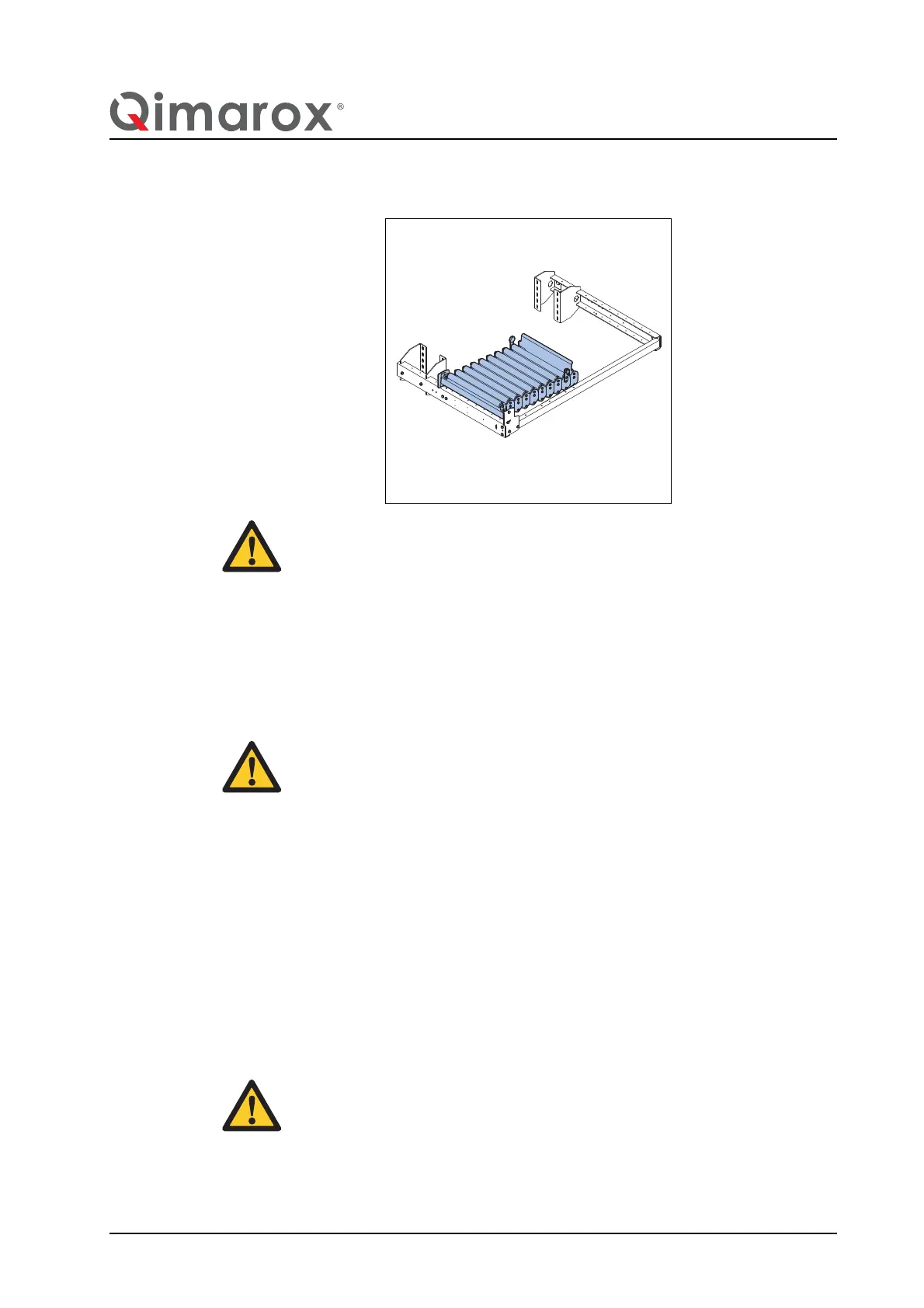

Maintenance gravity roller conveyor

10 Maintenance gravity roller conveyor

10.1 Specific safety regulations

For optimum functioning of the machine the various machine parts must be regularly

maintained. In this way defects and inaccuracies of the machine are prevented.

WARNING

• The maintenance as described in this chapter is based on 2000 running

hours per year. Adjust the maintenance frequency to the actual number of

running hours per year.

• If required, Qimarox can carry out the maintenance activities.

DANGER

• Only a qualified maintenance engineer is allowed to carry out mainte-

nance activities on the machine. Refer to section 3.2.

• Switch the machine off using the main power supply switch before

starting any maintenance or repair activities. Secure the main power

supply switch with a padlock.

• Do not use any corrosive and inflammable solvents or cleaning

agents on the machine that contain TRI, PER, TETRA or FCHC. Read

the instructions on the packaging when use is made of chemical sub-

stances (cleaning agents).

• After having completed maintenance activities, always put all safety

provisions that have been removed in place again.

• Make sure that the machine has always run empty before carrying

out any activities. No products must be present in the machine.

• Take the appropriate measures for safely working at heights.

WARNING

Avoid parts made of rubber or plastic, such as cables and gaskets, from

making contact with oil, solvents or other chemicals.

Loading...

Loading...